Process Method for Closed Die Forging of Middle Input Shaft of Loader

A closed die forging and process method technology, applied in the field of machining, can solve the problems of high mold manufacturing cost, poor working environment, poor precision, etc., and achieve the effects of high production efficiency, good surface quality, and long mold life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

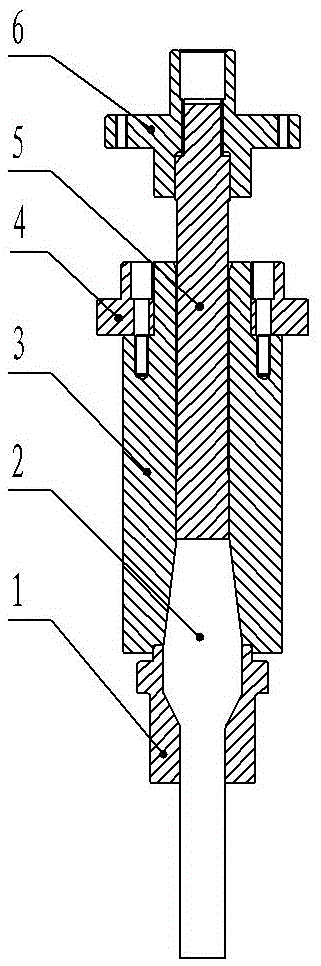

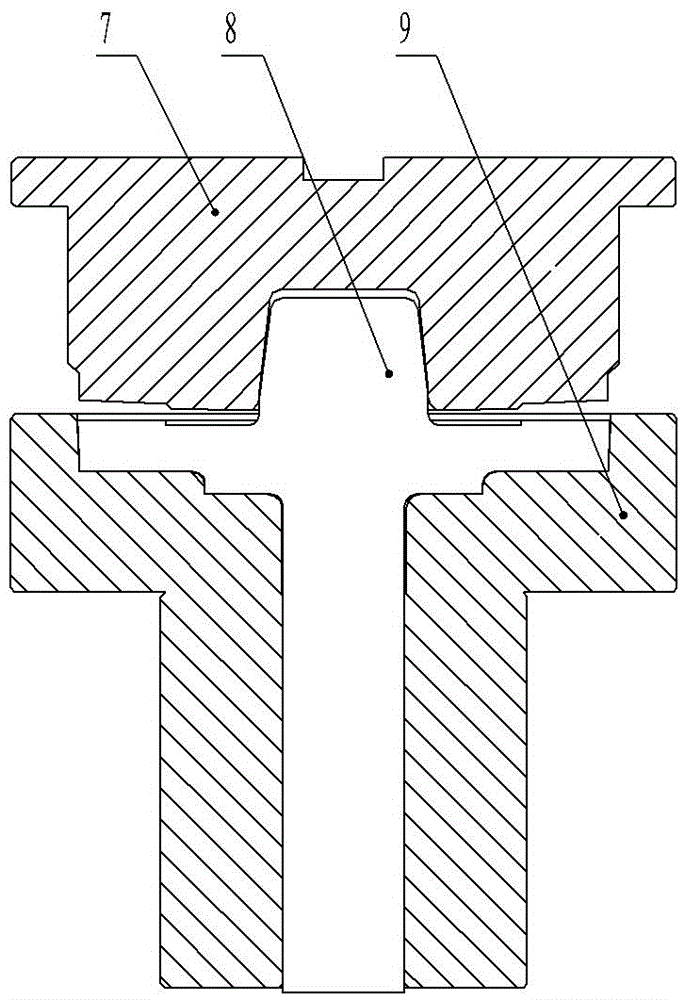

[0019] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail: as Figure 1~Figure 2 as shown,

[0020] A process method for closed die forging of an intermediate input shaft of a loader, comprising the following steps:

[0021] A. Cutting: Use a band saw to saw the round steel into a round bar of the size required by the process;

[0022] B. Heating: Put the round bar sawed in step A into the intermediate frequency furnace for heating, and the heating temperature is controlled at 1150°C±50°C;

[0023] C. Billet making: Put the heated round bar into the pre-upsetting machine for pre-upsetting. The pre-upsetting adopts the pre-upsetting die, and the final forging temperature is controlled at 1050 ° C ± 50 ° C;

[0024] D. Forming: Move the billet prepared in step C to a rotary rolling machine for rotary rolling, and the forming mold is a rotary rolling die, and the final forging temperature is controlled at 900°C~950°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com