Static pressure tong-type fire door cleaning method and cleaner thereof

A cleaning method and cleaning device technology, which are applied in the field of metallurgical industry, can solve the problems of shortening the normal service life of blast furnaces, affecting normal production, and low cleaning efficiency, so as to achieve large direct and indirect economic benefits, reduce shutdown maintenance rates, and reduce maintenance The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

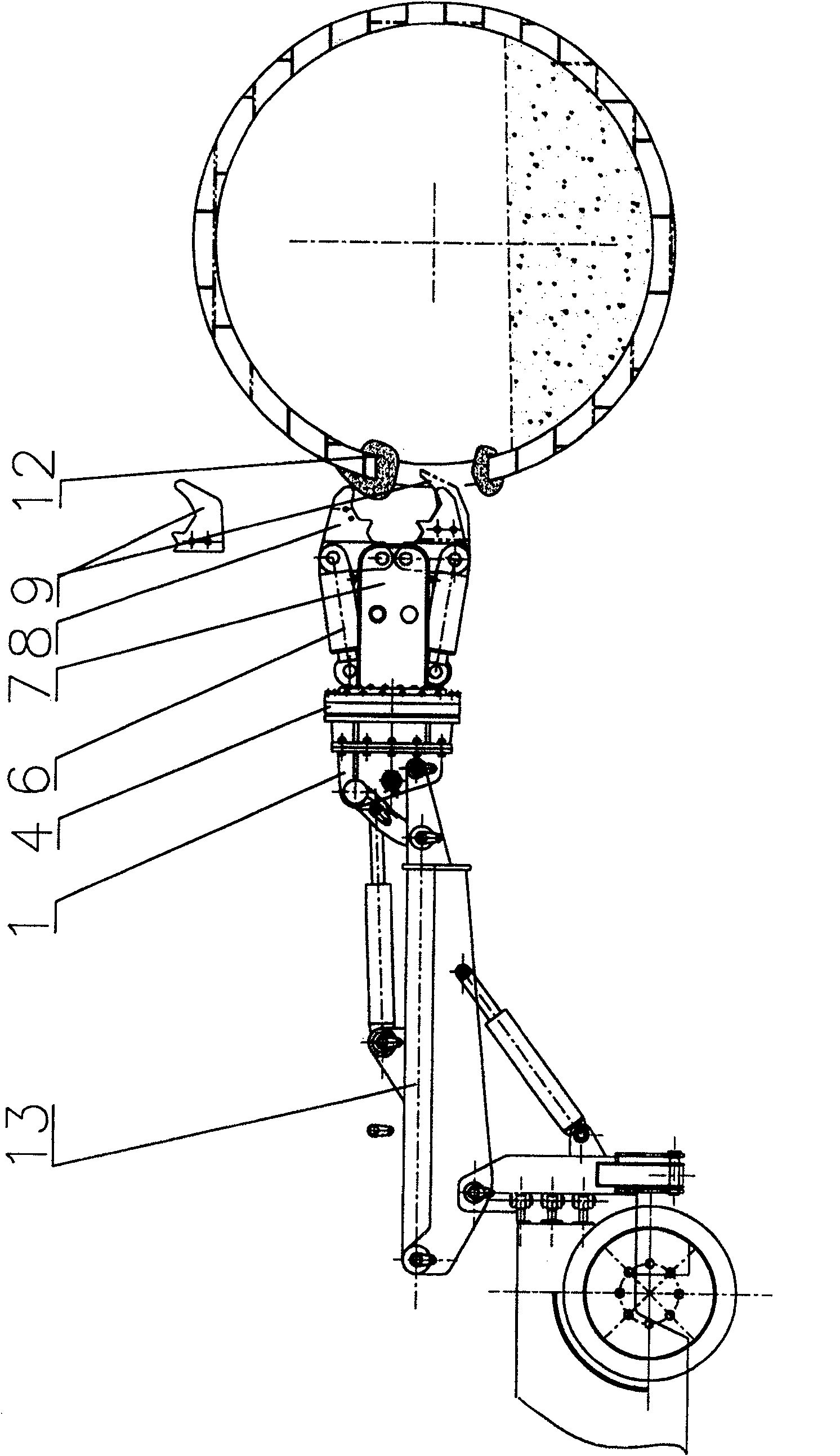

[0021] The method for cleaning the static pressure pliers-type furnace mouth of the present invention is to first clamp the slagging of the furnace mouth with a 360-degree rotatable tongs, and then use the thrust of the hydraulic cylinder to close the tongs, and the clamped slag is received by the oil cylinder. Huge thrust, crushing and crushing, low noise, no vibration and impact, small dust and high efficiency during cleaning.

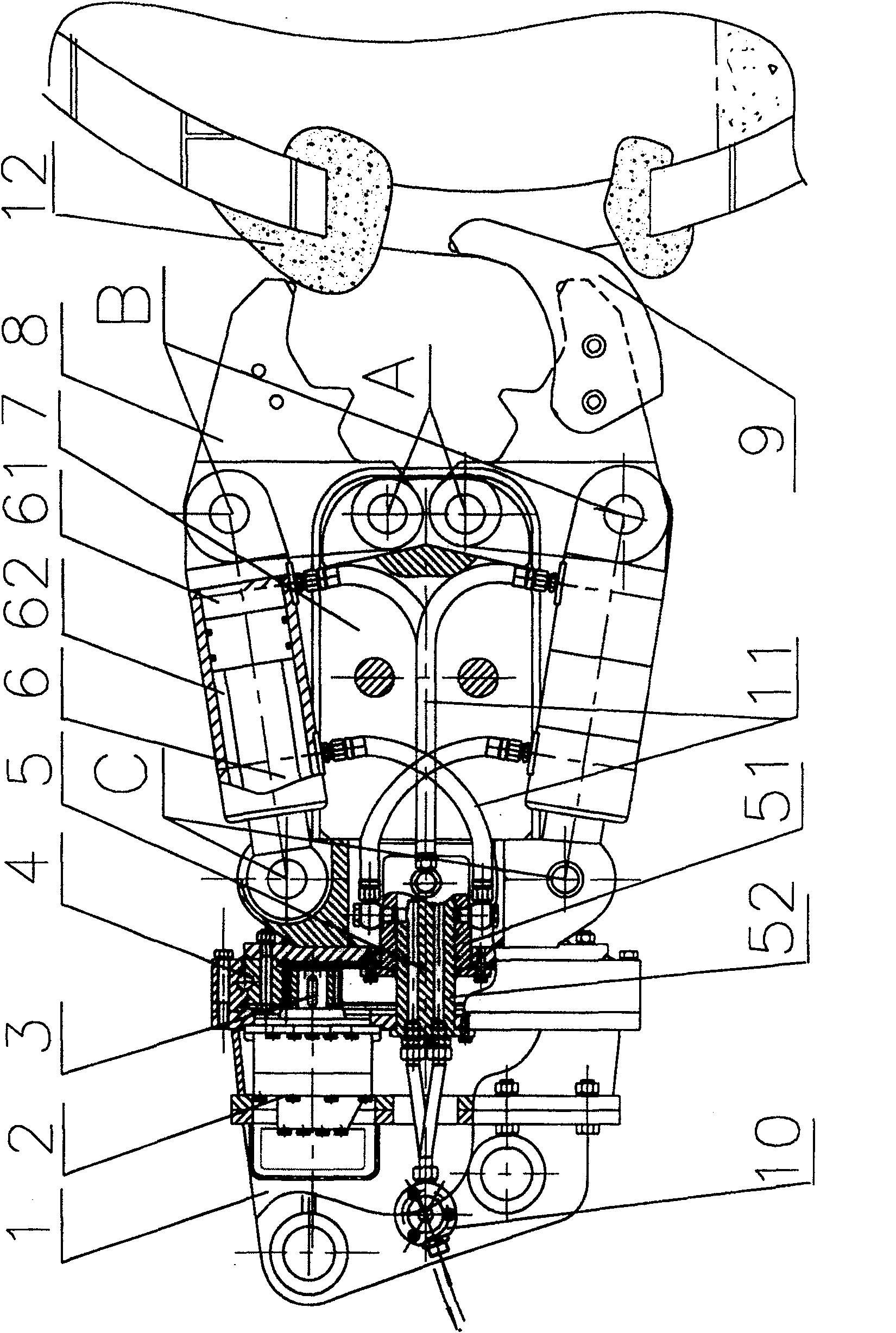

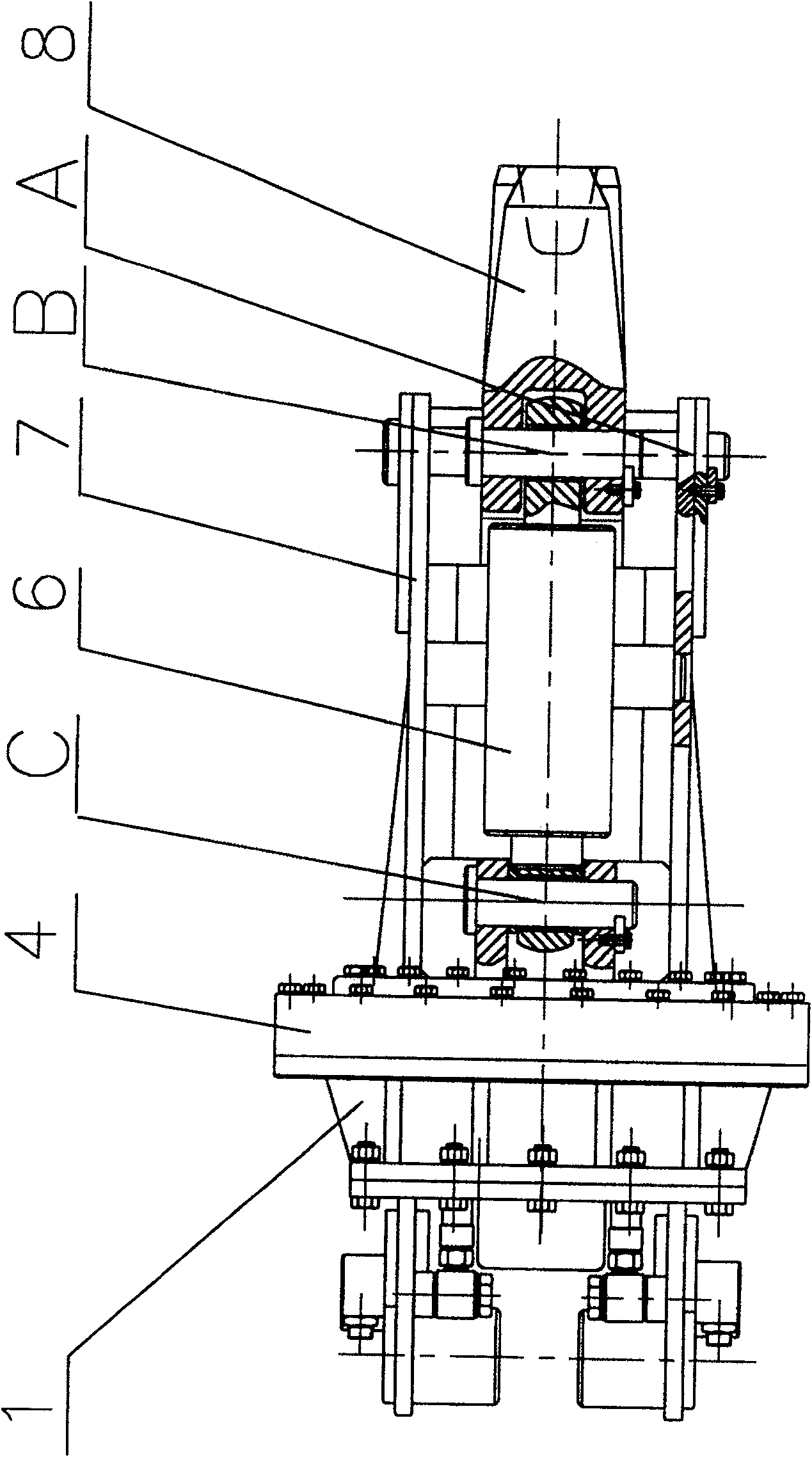

[0022] Such as figure 1 , 2 As shown, the static pressure pliers-type furnace mouth cleaner designed for the above method includes an upper connecting seat 1, an oil motor 2, a pinion 3, a slewing bearing 4, a central swivel joint 5, an oil cylinder 6, a bracket 7 and a clamp 8 , the oil motor 2 is fixed on the stop coupling seat 1, the output shaft of the oil motor 2 is provided with a pinion 3, the slewing bearing 4 is composed of a relatively rotatable outer ring and an inner gear ring, the outer ring of the slewing bearing 4 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com