Equipment for directly growing sapphire fairing

A technology of sapphire and fairing, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of sapphire fairing processing difficulty, low processing accuracy, and high production cost, so as to reduce the workload of subsequent processing, The effect of high processing precision and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

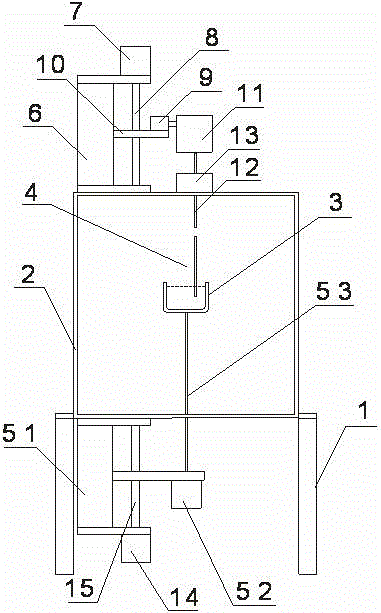

[0024] Example: see figure 1 , a device for directly growing sapphire fairings, including a frame 1, a furnace body 2, a crucible 3, and a capillary guide mold 4, the furnace body 2 is installed on the frame 1, and the crucible 3 is installed in the furnace body 2. During specific implementation, the equipment also includes a control system, through which the furnace temperature of the furnace body 2 can be controlled, the moving speed of the lateral movement mechanism and the longitudinal movement mechanism, and the rotational speed of the torque motor and the rotating assembly, so that the formed fairing The blank is closer to the fairing to reduce subsequent processing, thereby improving the production speed and efficiency of the sapphire fairing.

[0025] A rotating assembly is arranged below the frame 1, and the rotating assembly includes a fixed frame 51, a rotating motor 52 and a transmission rod 53, the transmission rod 53 is vertically arranged, one end of which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com