A method for preparing carbon fiber composite automotive parts

A technology of auto parts and composite materials, which is applied in the field of auto parts manufacturing, can solve the problems of small annual consumption of carbon fiber composite materials, lack of mass connection technology, difficulty in large-scale production, etc., and achieve semi-automatic or automatic production. The effect of strong design and easy control of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

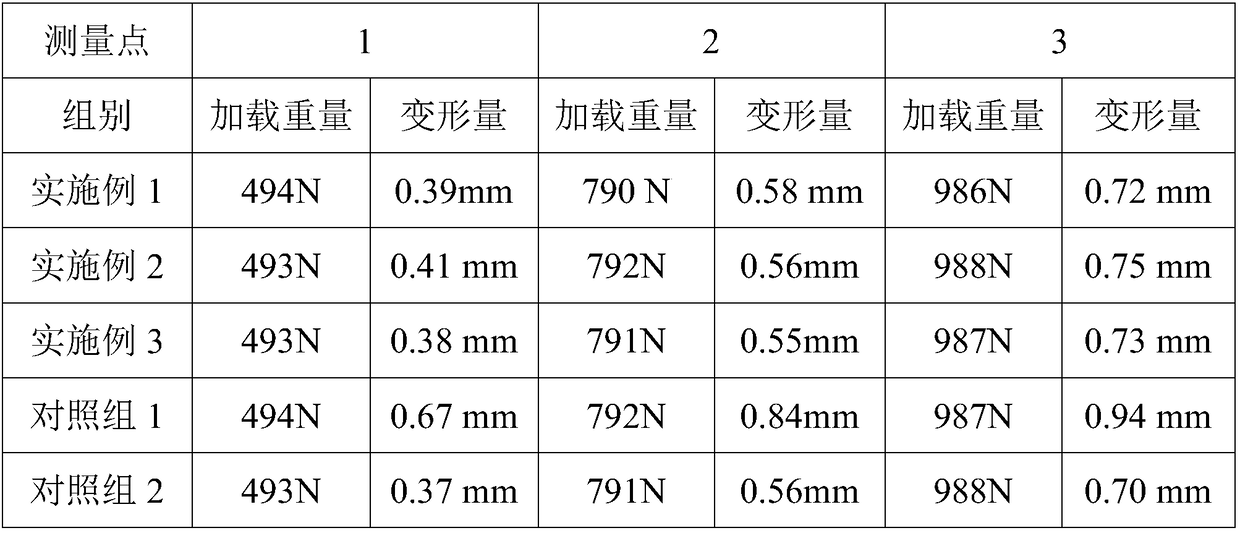

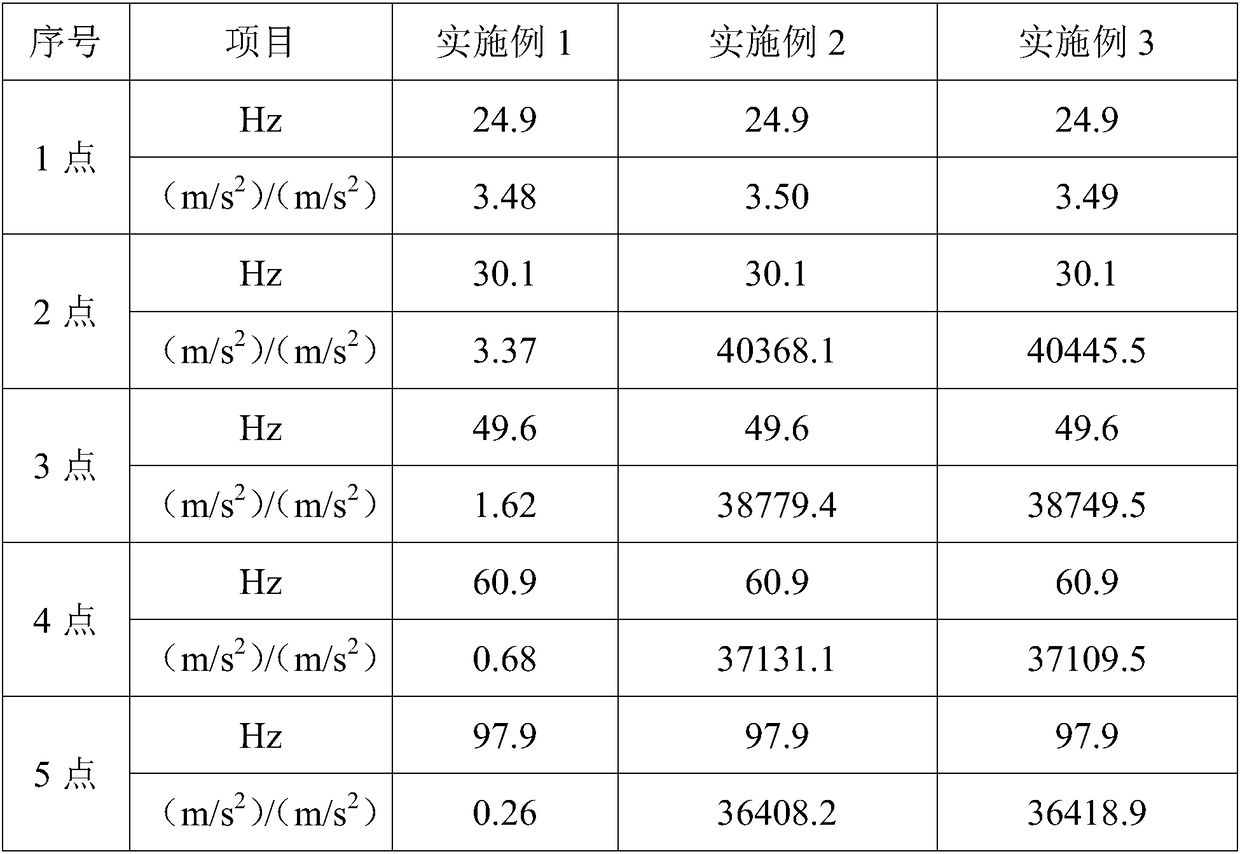

Examples

Embodiment 1

[0030] A method for preparing carbon fiber composite auto parts, comprising the following steps:

[0031] 1) Preparation of carbon fiber fabric:

[0032] 1.1) The polyacrylonitrile precursor is subjected to high-temperature carbonization treatment under the protection of an inert gas, so that all polar groups are cracked and escaped, and the carbon content on the surface of the carbon fiber is ≥ 92%;

[0033] 1.2) Using the anodic oxidation method, put the carbonized carbon fiber in step 1.1) into the electrolytic solution for 10 minutes and electrolyze it for 10 minutes, use a graphite plate or metal plate as the cathode, use the carbon fiber as the anode, and use organic acid, inorganic acid, salt or alkali As an electrolyte solution, hydrophilic groups are introduced on the surface of carbon fibers;

[0034] 1.3) use 5wt% (NH 4 ) 2 HPO 4 The solution was boiled for 15 minutes, rinsed three times with deionized water, and dried in an oven at 120°C for 3 hours;

[0035]1...

Embodiment 2

[0045] A method for preparing carbon fiber composite auto parts, comprising the following steps:

[0046] 1) Preparation of carbon fiber fabric:

[0047] 1.1) The polyacrylonitrile precursor is subjected to high-temperature carbonization treatment under the protection of an inert gas, so that all polar groups are cracked and escaped, and the carbon content on the surface of the carbon fiber is ≥ 92%;

[0048] 1.2) Using the anodic oxidation method, put the carbonized carbon fiber in step 1.1) into the electrolyte solution for electrolysis for 15 minutes, use graphite plate or metal plate as cathode, carbon fiber as anode, and organic acid, inorganic acid, salt or alkali As an electrolyte solution, hydrophilic groups are introduced on the surface of carbon fibers;

[0049] 1.3) use 5wt% (NH 4 ) 2 HPO 4 The solution was boiled for 22 minutes, washed three times with deionized water, and dried in an oven at 120°C for 3 hours;

[0050] 1.4) The carbon fibers treated in step 1...

Embodiment 3

[0060] A method for preparing carbon fiber composite auto parts, comprising the following steps:

[0061] 1) Preparation of carbon fiber fabric:

[0062] 1.1) The polyacrylonitrile precursor is subjected to high-temperature carbonization treatment under the protection of an inert gas, so that all polar groups are cracked and escaped, and the carbon content on the surface of the carbon fiber is ≥ 92%;

[0063] 1.2) Using the anodic oxidation method, put the carbonized carbon fiber in step 1.1) into the electrolytic solution for 20 minutes and electrolyze it for 20 minutes, use a graphite plate or metal plate as the cathode, use the carbon fiber as the anode, and use organic acid, inorganic acid, salt or alkali As an electrolyte solution, hydrophilic groups are introduced on the surface of carbon fibers;

[0064] 1.3) use 5wt% (NH 4 ) 2 HPO 4 The solution was boiled for 30 minutes, rinsed three times with deionized water, and dried in an oven at 120°C for 3 hours;

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com