Sewage preprocessing multifunctional solid-liquid separator

A solid-liquid separator and sewage pretreatment technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, filtration and separation, etc. It can solve the problems of inconvenient sludge discharge, single function, and power consumption for operation. Achieve the effect of simple maintenance and repair, simple process, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

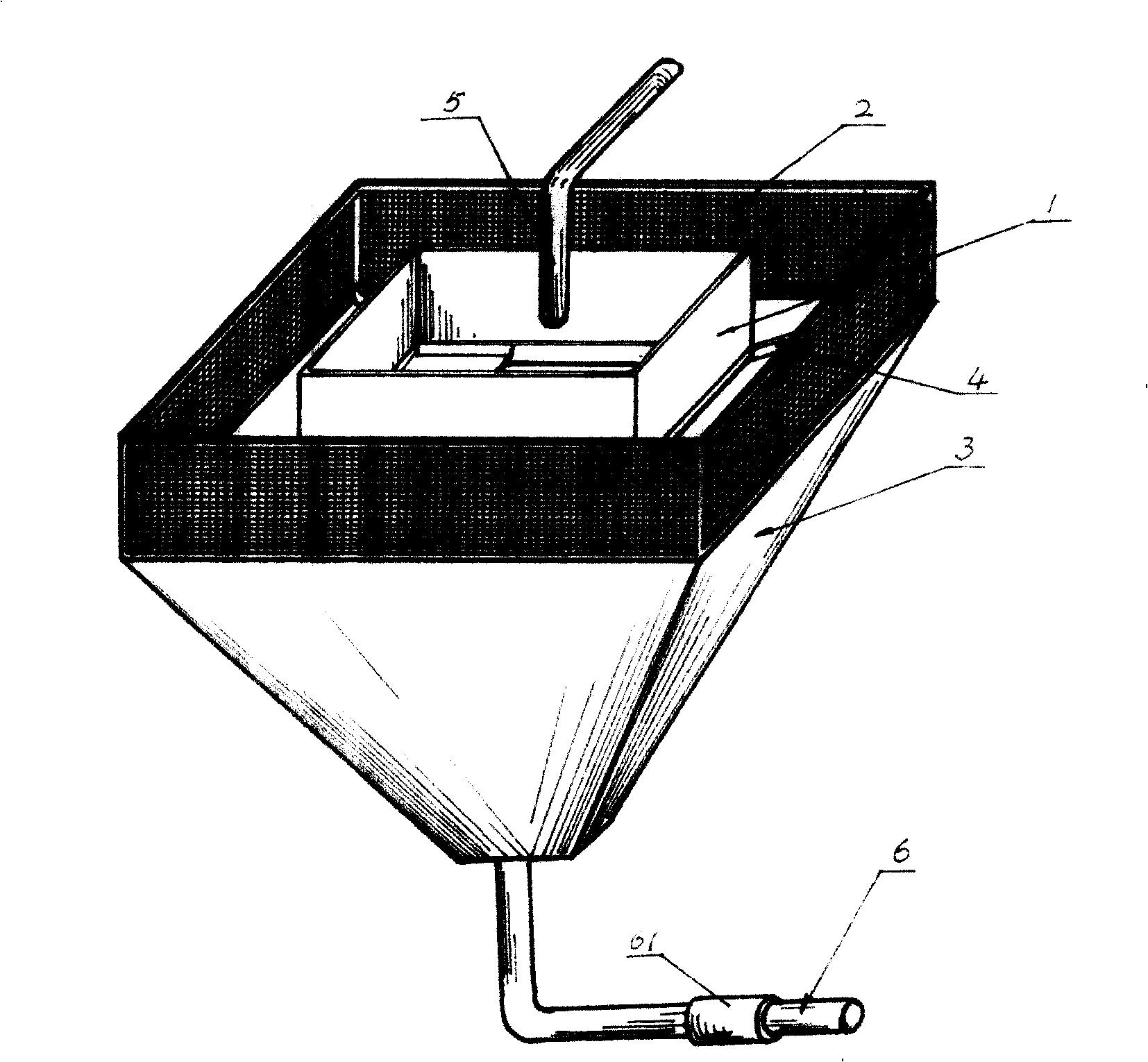

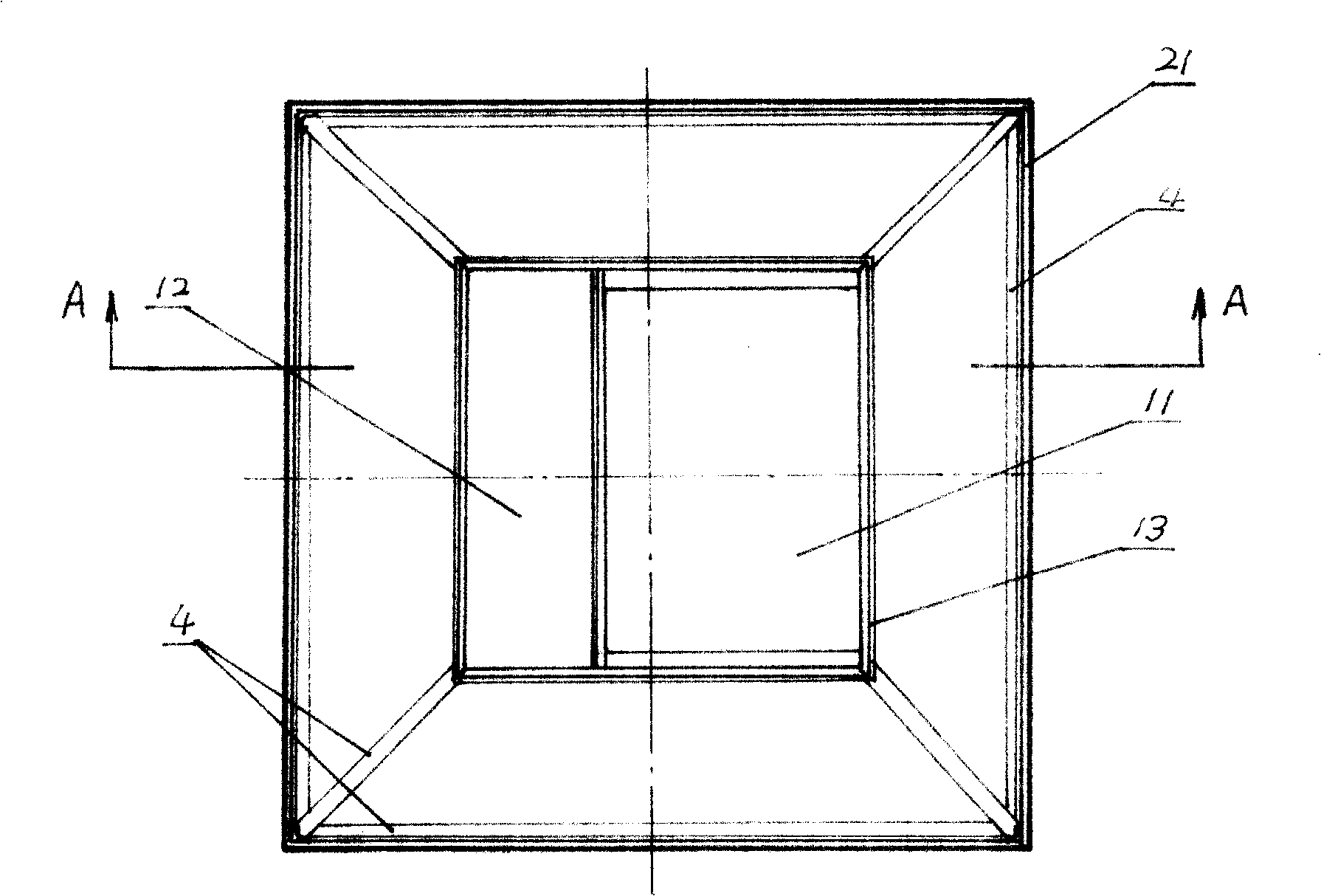

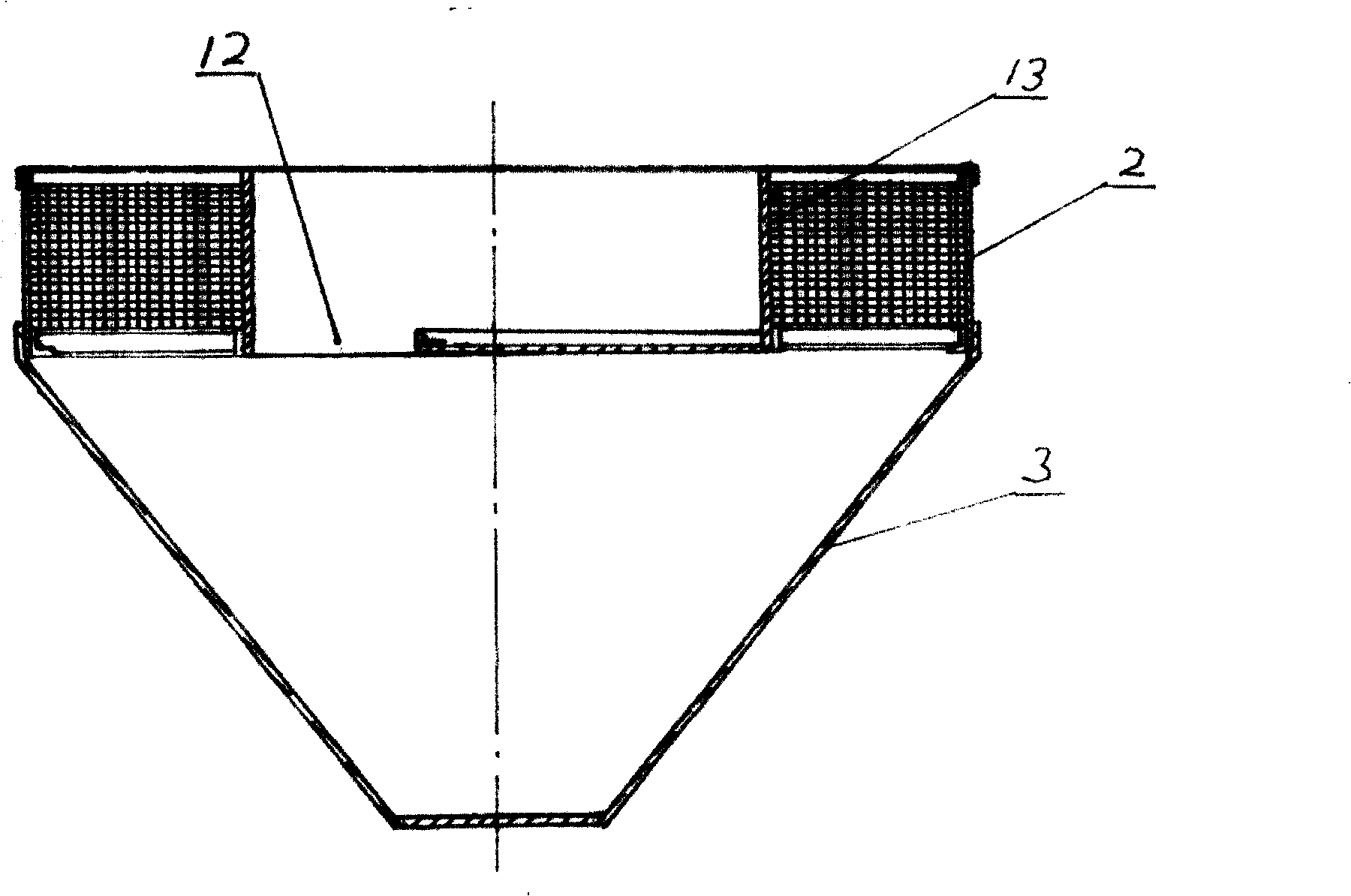

[0013] Depend on figure 1 , figure 2 and image 3 As shown, a multifunctional solid-liquid separator for sewage pretreatment is mainly composed of a retarder box 1, an intercepting net 2, a dirt receiving bucket 3, a frame structure 4, a water inlet pipe 5 and a mud discharge pipe 6, wherein: the retarder box 1. It consists of a box wall 13 surrounded by four rectangular flat plates and a square box bottom 11. The top of the slow box 1 has no cover, and part of the box bottom 11 is separated from the dirt bucket 3 by the bottom cover 14. The other part is left The flush opening 12 communicates with the space of the dirt bucket 3, and the overall structure of the retarder box 1 is connected to the middle part of the upper part of the dirt bucket 3 through the frame structure 4; the interception net 2 is surrounded by four rectangular mesh walls 21, And through the frame structure 4, it is connected with the surrounding structure of the upper part of the dirt bucket 3; under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com