Plastering machine capable of plastering multiple sections of wall surfaces in one-time positioning mode

A plastering machine and column technology, which is applied in the direction of construction and building structure, can solve the problems of unreachable, insufficient flatness of the wall, and the material of the storage hopper cannot be wiped to the top of the wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

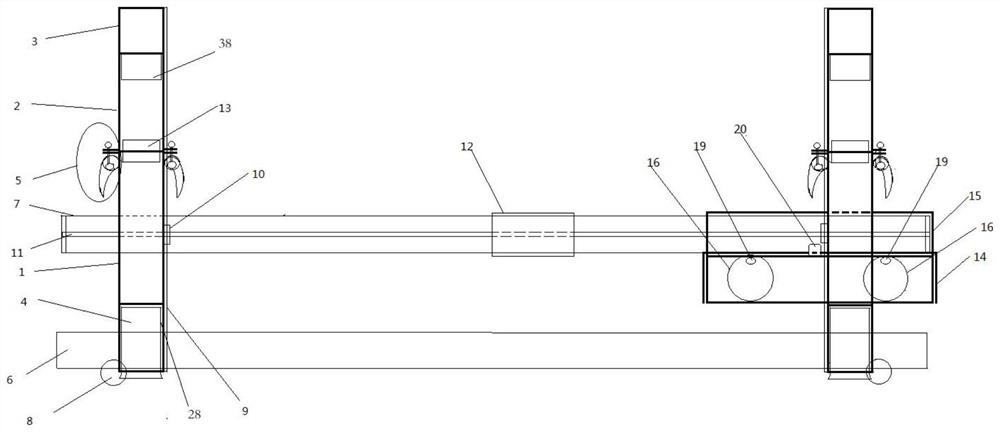

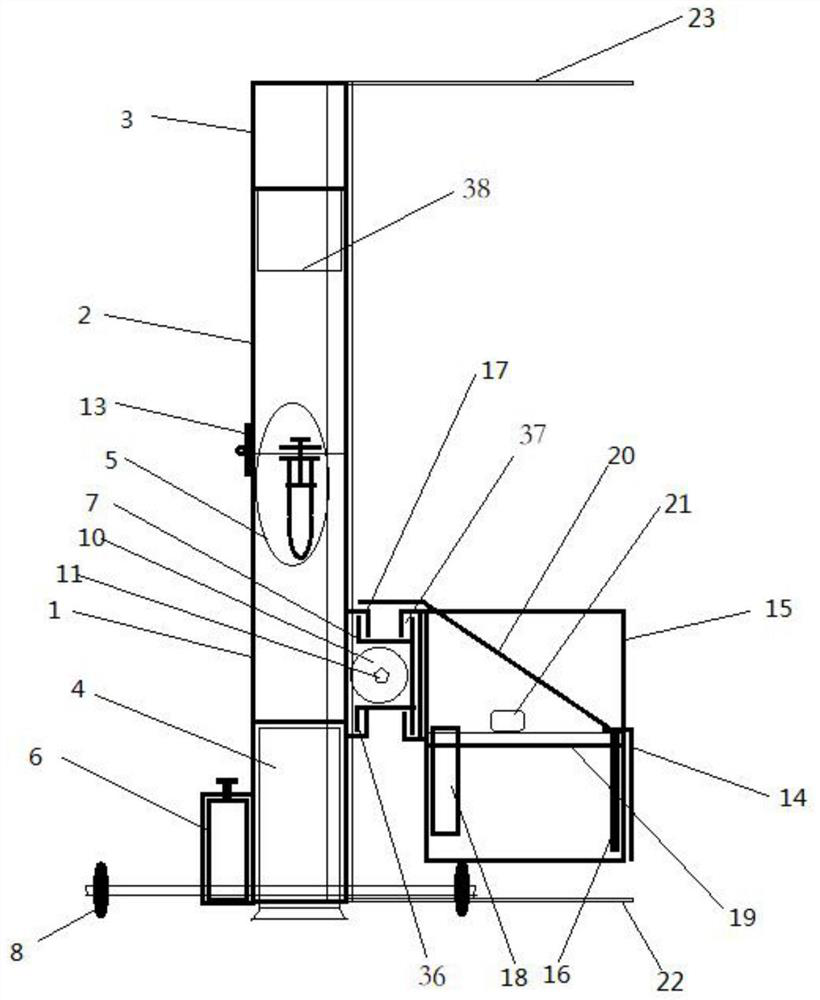

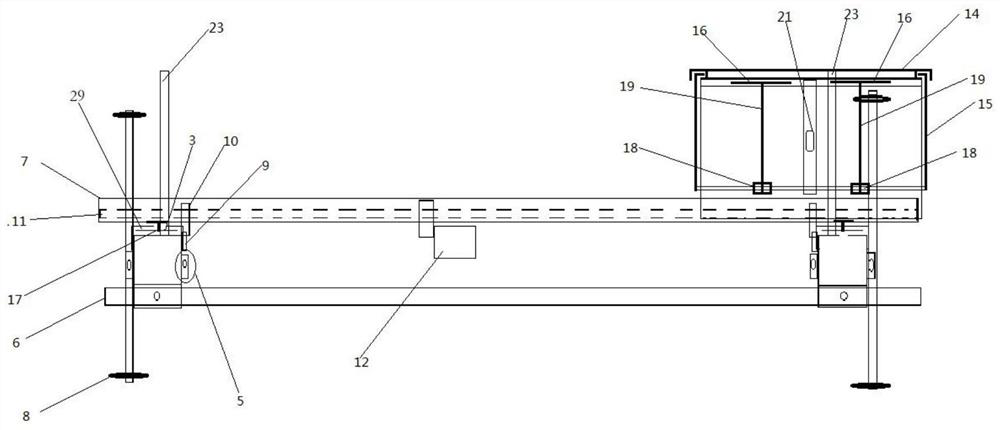

[0042] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention includes a horizontally arranged track 7 and two spaced and spaced column assemblies, and the bottom ends of the two column assemblies are connected to a column connecting pipe 6 through a joint guide sleeve. The union guide sleeve is provided with locking bolts for locking the column connecting pipe 6, respectively pass the two ends of the column connecting pipe 6 through the two union guide sleeves, and adjust the gap between the two column assemblies as required. distance, and then lock the column connecting pipe 6 through the locking bolt, so as to realize the relative fixation of the two column assemblies, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com