Plastering construction method and plastering device

A construction method and plastering board technology, applied in the field of plastering, can solve problems such as cracks or cracks, achieve the effects of increasing bonding strength, improving plastering efficiency, and reducing the possibility of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

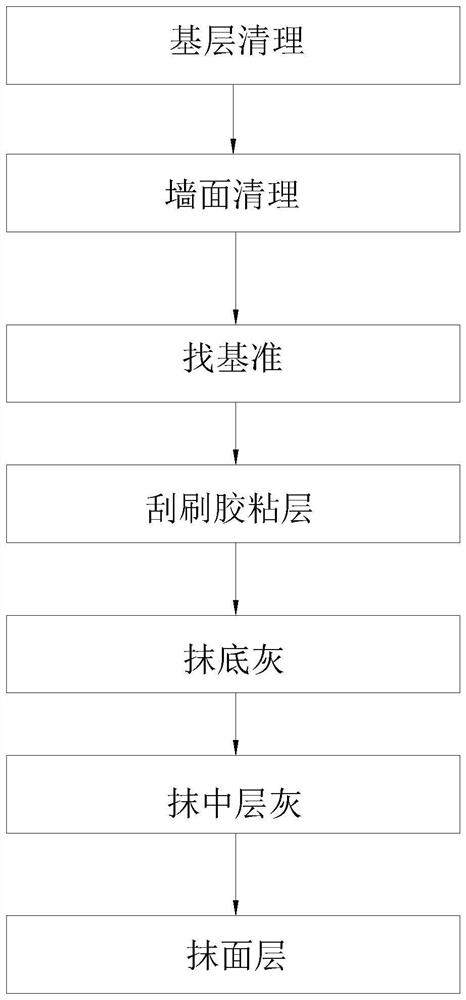

[0050] refer to figure 1 , the plastering construction method includes the following steps:

[0051] S1. Basic cleaning: remove the residual mortar, dust and oil stains on the wall, and fill in the gaps and defects, so as to increase the flatness of the wall and facilitate plastering construction.

[0052] S2. Wet the wall: spray water from top to bottom on the wall that needs to be plastered, and the water penetrates 8-10mm into the wall to clean up the dust and other debris left on the wall.

[0053] S3. Find the benchmark: Take the wall as the benchmark, and make a benchmark plane parallel to the corresponding wall at a distance of 25-100mm from the wall, that is, the distance between the benchmark and the wall is greater than or equal to the plastering thickness. The specific steps are as follows:

[0054] Pop up a cross line on the ground as a guideline. According to the flat and vertical condition of the base surface of the wall, the plastering thickness is determined w...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that in steps S4, S5, S6 and S7, a plastering device is used to apply adhesive, bottom ash, middle layer ash and surface layer mortar respectively in sequence.

[0064] In step S3, the following method is used to find the benchmark: take the wall as the benchmark, and set at least two vertically distributed light emitters 7-25 mm away from the wall, and the light emitters are laser emitters or infrared projectors, preferably infrared projectors. line meter and the light emitter is multi-line emission.

[0065] Specifically, the light emitter emits two mutually perpendicular rays, and the two rays are respectively parallel to two adjacent wall surfaces, and the plane where the rays of the multiple light emitters parallel to the same wall are located is used as the reference plane , taking the passing light as the positioning reference, which can effectively reduce the error of the reference plane caused by the ca...

Embodiment 3

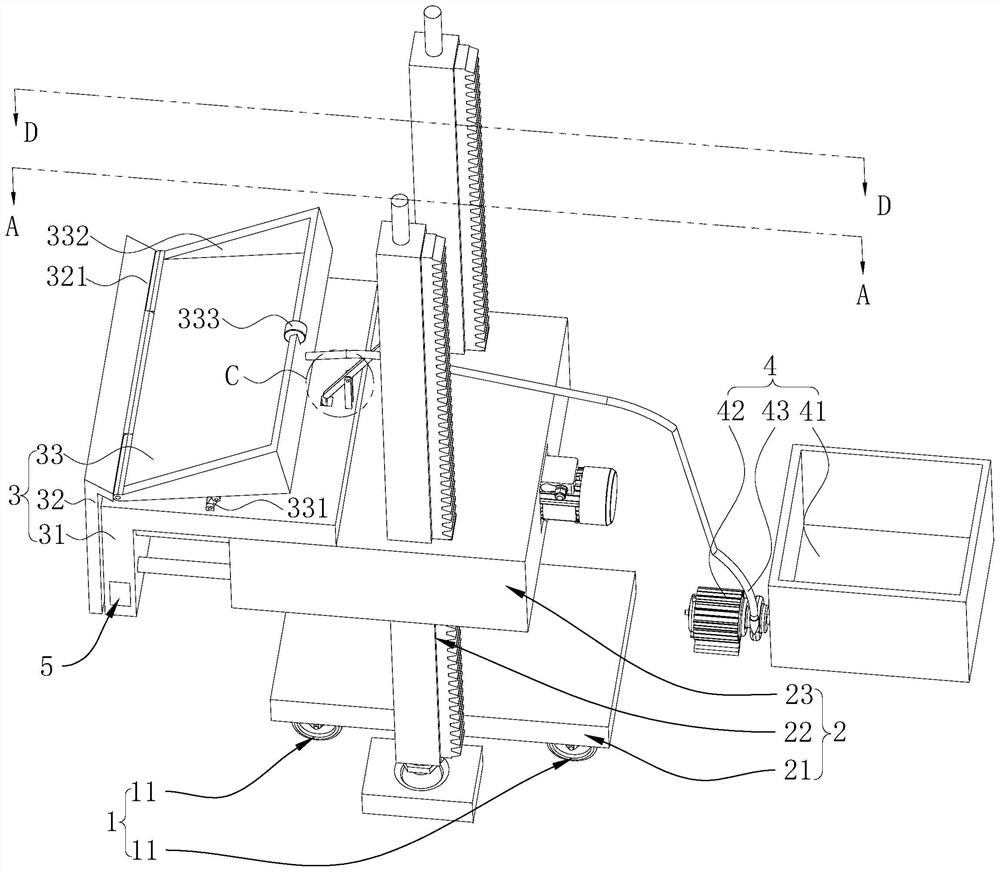

[0067] The embodiment of the present application also discloses a plastering device, refer to figure 2 and image 3 , the plastering device includes a base frame 1, a lifting mechanism 2 arranged on the base frame 1 and a plastering mechanism 3 for plastering. Wherein, the plastering mechanism 3 is arranged at the lifting end of the lifting mechanism 2 .

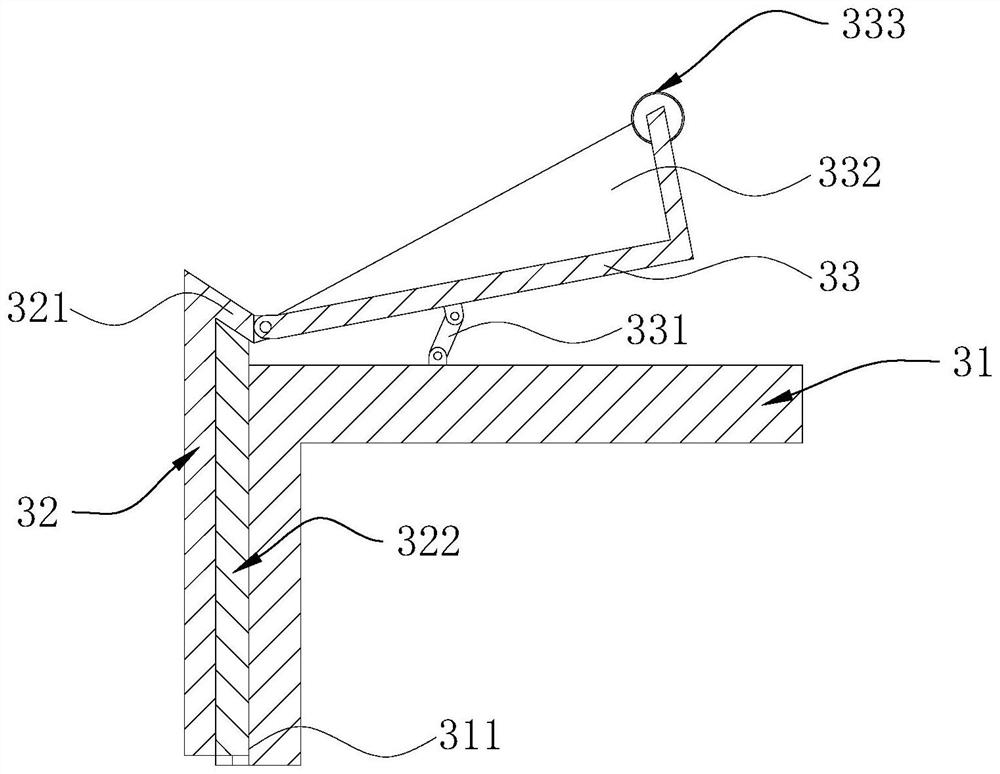

[0068] The plastering mechanism 3 includes a plastering seat 31, a plastering plate 32 and a slurry storage plate 33 for storing mortar or adhesive. The plastering seat 31 is fixedly connected to the lifting end of the lifting mechanism 2, and the plastering plate 32 is connected by sliding vertically. On the side of the plastering seat 31, the plastering plate 32 can slide vertically above the plastering seat 31, and the slurry storage plate 33 is inclined.

[0069] refer to figure 2 and image 3 , the slurry storage board 33 is used to provide mortar or adhesive for the plastering board 32, the edge of the slurry sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com