A masonry plastering construction mechanism

A technology of masonry and mortar tanks, applied in building construction, processing of building materials, construction, etc., can solve problems such as inconvenient plastering, and achieve the effect of ensuring strength, ensuring flatness, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

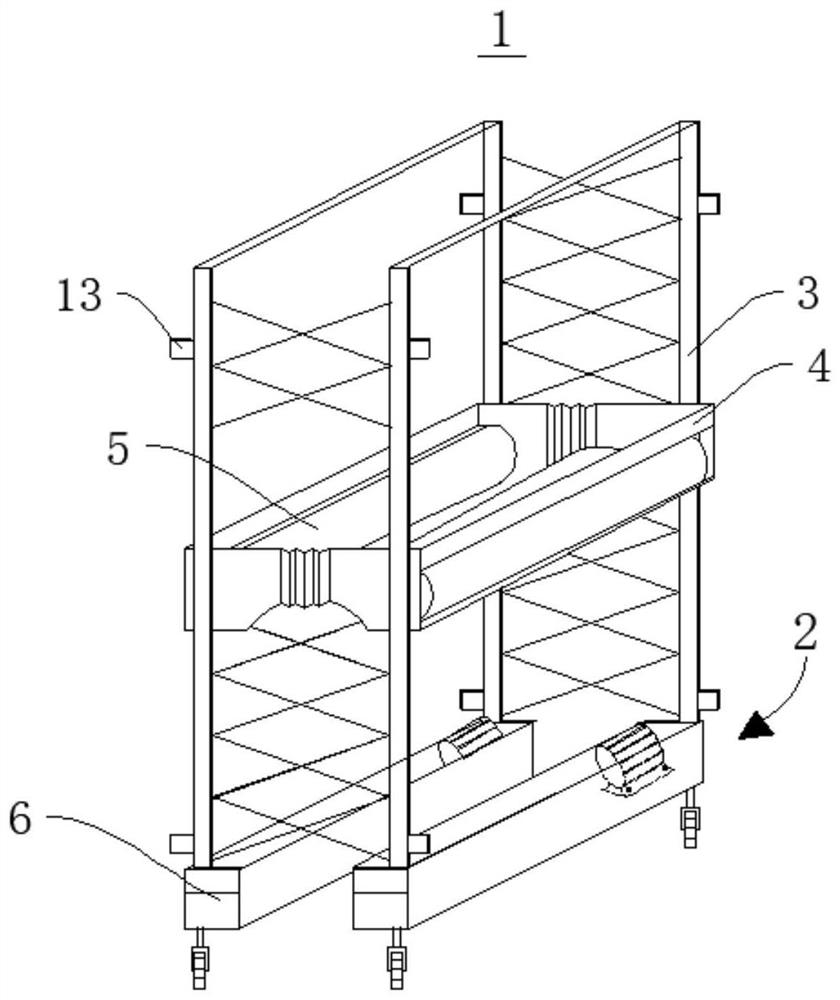

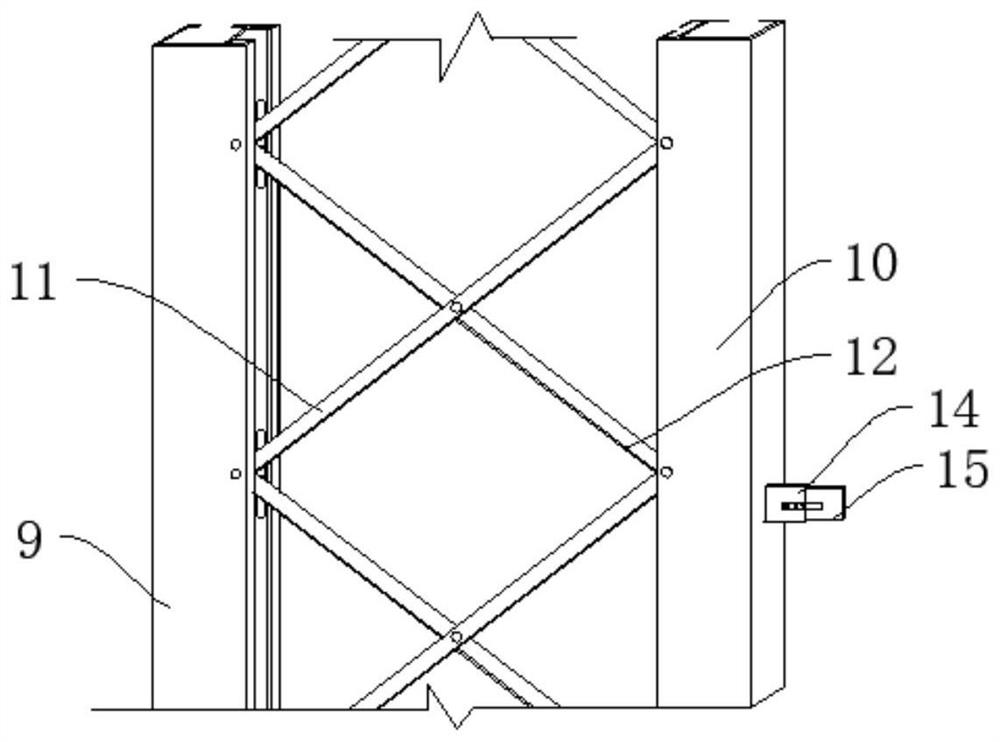

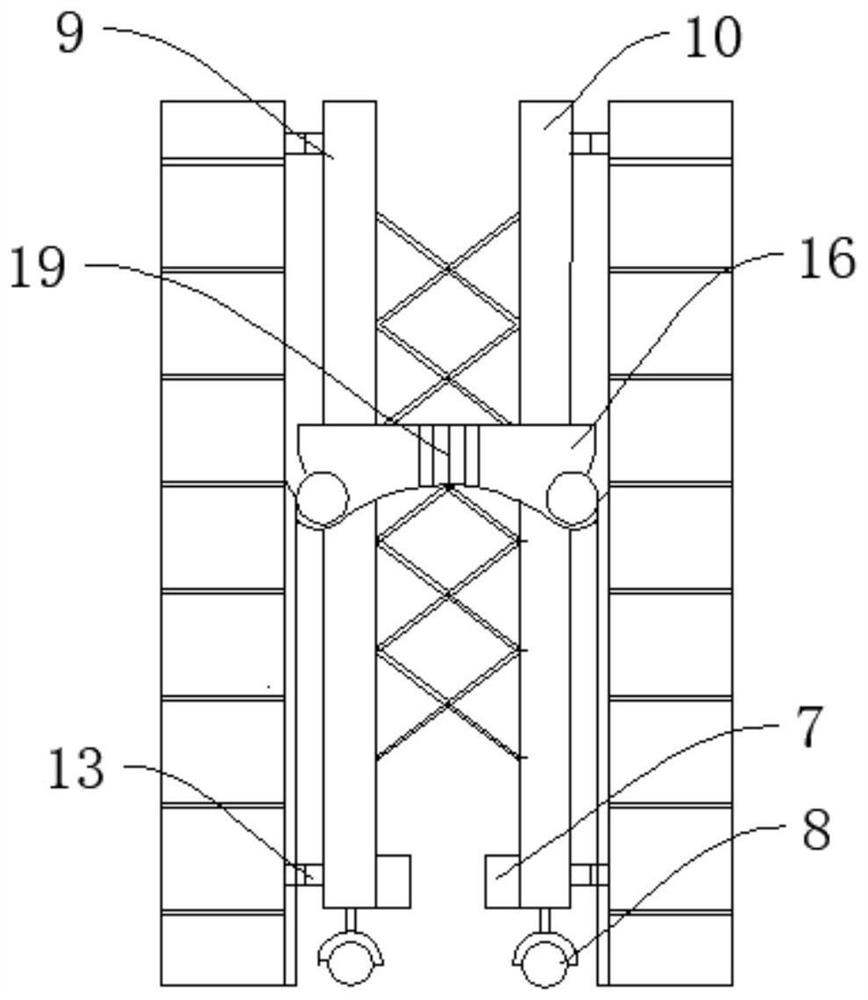

[0036] Please refer to figure 1 , Cooperation with reference Figures 2 to 4, There is provided a masonry plastering construction mechanism 1 of the present application, comprises a base 2, two horizontal telescopic member 3, the lift assembly 4 feed cylinder 5, and two plaster, the base 2 comprises two support assembly 6; wherein, two horizontal telescopic assembly 3 are horizontally telescopically mounted on each support assembly 6; 4 lift the feed assembly mounted for vertical movement on two horizontal telescopic assembly 3; on opposite sides of the lift feed assembly 4 are rotatably plastering drum 5 is mounted, the telescopic assembly 3 for two horizontal spacing between the two rollers 5 plastering adjustment, the lift assembly 4 for supplying feed to the feed drum 5 plastering.

[0037] Please refer to figure 1 , Each support assembly 6 includes a plurality of casters supporting frame 7 and 8, each of the support frame 7 are attached to the bottom of the plurality of caster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com