Automatic plastering machine

A wall plastering machine and automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of equipment failure, large area of space cannot be plastered, time-consuming and other problems, and achieve convenient and reliable adjustment, high plastering efficiency, and vertical rail rigidity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

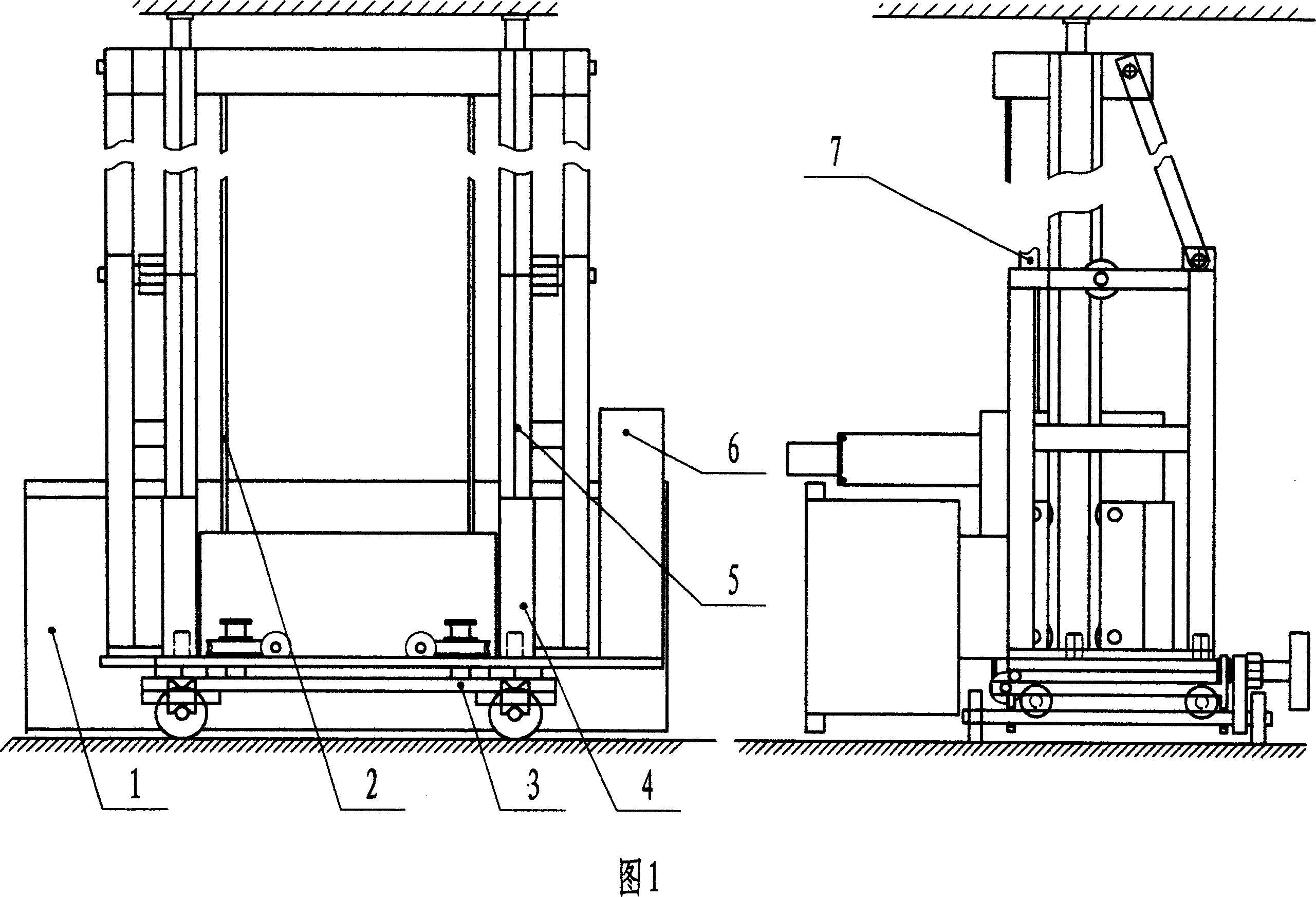

[0034] In Figure 1:

[0035] The wall plastering machine is composed of a main box (1), a steel wire rope (2), a base (3), a sliding sleeve (4), a vertical frame (5), a laser wall measuring instrument (6), and a vertical sensor (7).

[0036] The main chassis (1) is connected on the sliding sleeve (4), and the sliding sleeve (4) is sleeved on the vertical rail (5-1) of the vertical frame (5), the vertical frame (5), the laser wall measuring instrument (6), The vertical sensor (7) is fixed on the base (3). Wire rope (2) is wound between the top beam (5-3) of main frame (1), vertical frame and base (3).

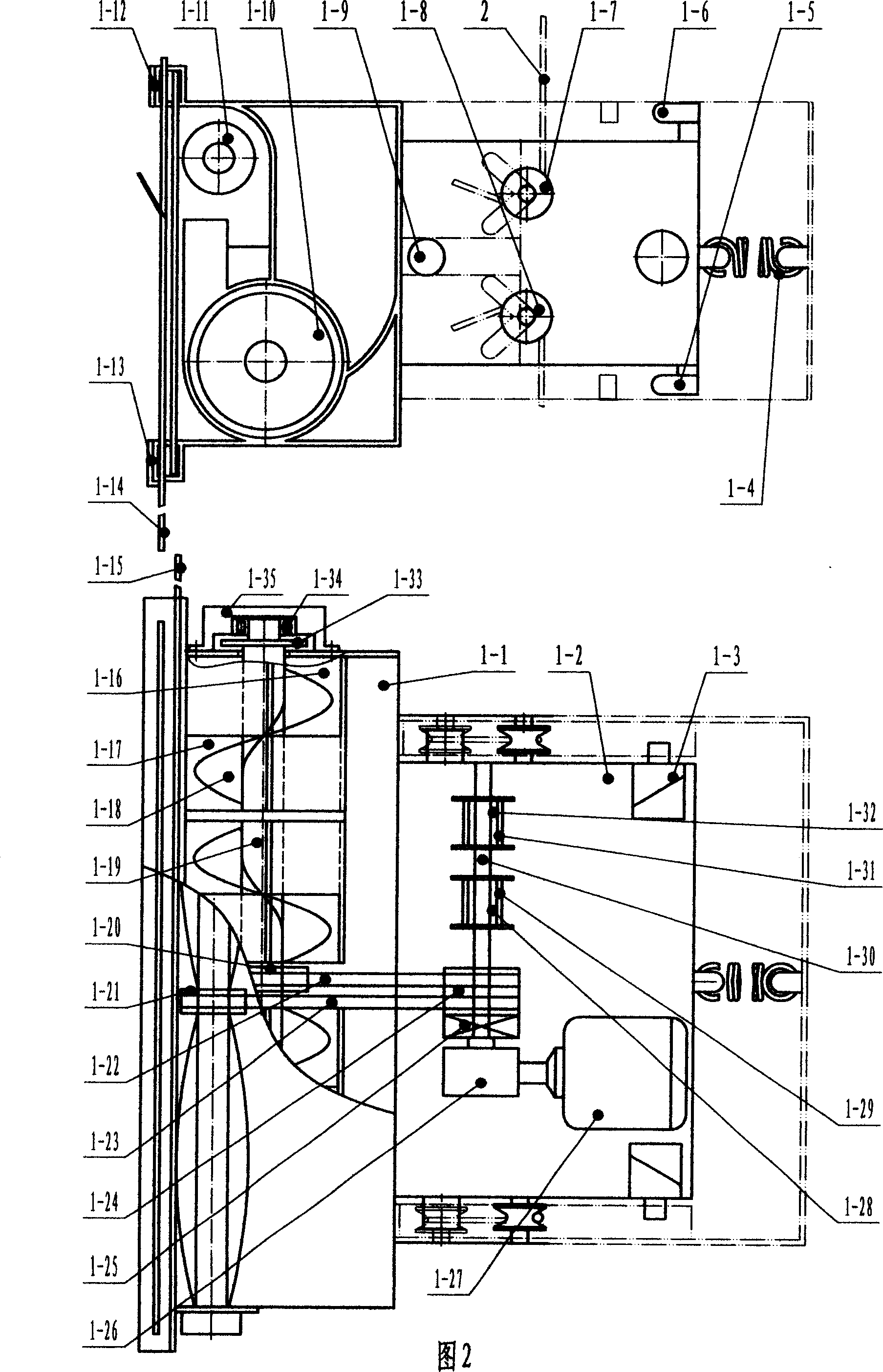

[0037] In Figure 2:

[0038] Main chassis (1) is made of hopper (1-1), power box (1-2).

[0039] The hopper (1-1) is composed of a multi-section screw feeder (1-10), a plastering board (1-11), an upper plastering board (1-12), a lower plastering board (1-13), a vertical inserting board ( 1-14), cross plate (1-15), belt pulley 1 (1-20), belt pulley 2 (1-21), belt 1 (1-22), be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com