Method for reducing emission of nitrogen oxides under low load of boiler

A nitrogen oxides, low-load technology, applied in combustion methods, emission prevention, fuels burned in a molten state, etc., can solve problems such as the decline of denitration efficiency, save ash cleaning and maintenance costs, reduce waste gas and sewage costs, and solve nitrogen problems. The effect of oxides exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

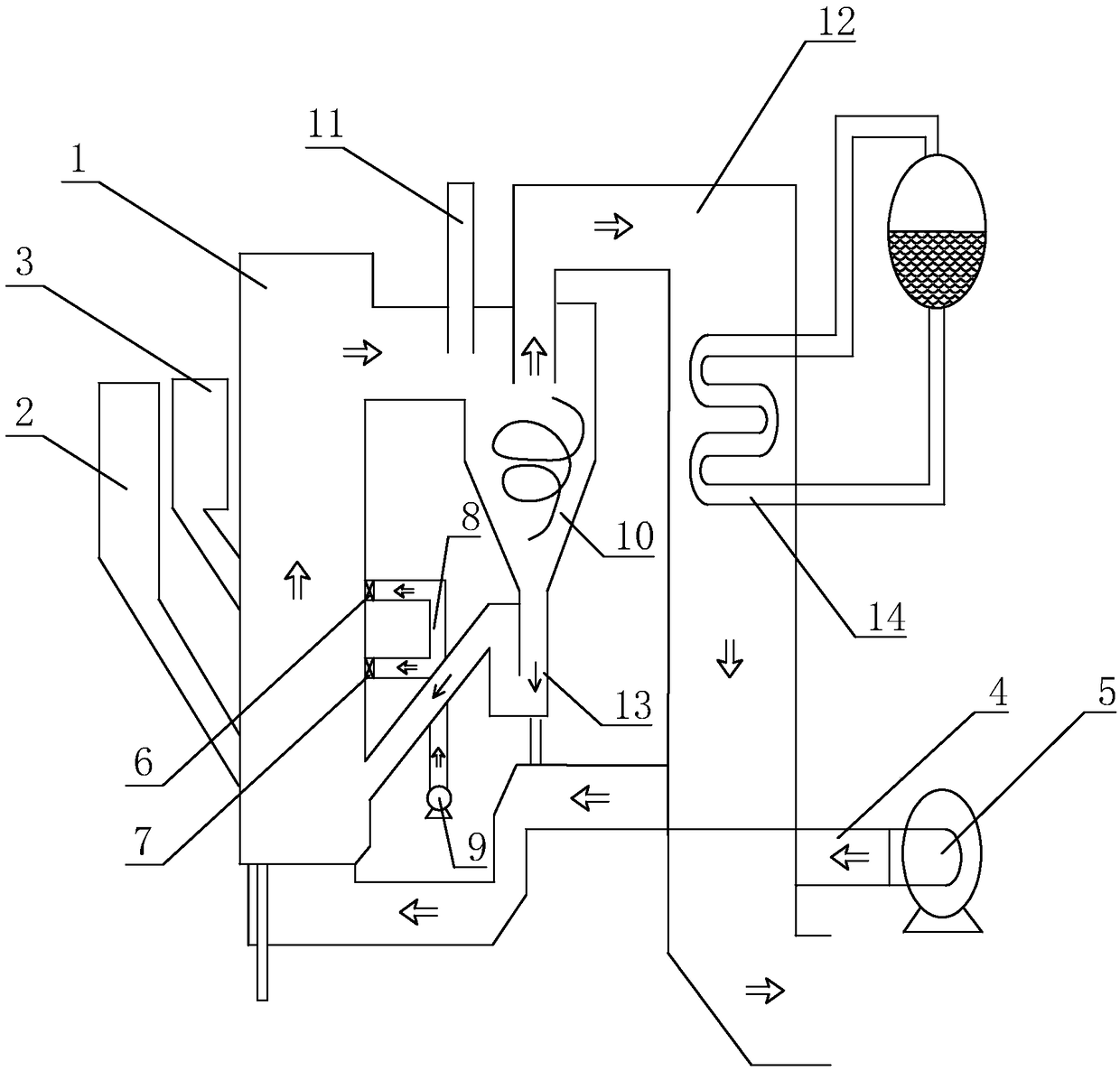

Embodiment 1

[0029] Embodiment 1: A method for reducing nitrogen oxide emissions under low boiler load. When the boiler load is less than or equal to 70t / h, the flue gas temperature at the boiler outlet is less than 770°C. At this time, the ammonia injection pipe 11 of the SNCR denitrification system is closed. The opening of the secondary air outlet baffle is maintained at 30%, the frequency of the secondary fan 9 is maintained at 11Hz, the boiler bed temperature is controlled at 850°C, and the oxygen content of the boiler is controlled to 3.5% by reducing the primary air volume to 5200Nm³ / H. The calcium-sulfur ratio of the limestone in the boiler is 4.5%, the desulfurizer limestone is injected continuously, and the secondary air distribution method for combustion in the boiler is: fully open the lower secondary damper 7 and fully close the secondary damper 6 , the average emission of nitrogen oxides is 112mg / Nm³.

Embodiment 2

[0030] Embodiment 2: The method for reducing nitrogen oxide emissions under the low load of the boiler is different from that of Example 1 in that the calcium-sulfur ratio of the limestone sprayed into the boiler is reduced from 4.5% to 4%, and the desulfurizer limestone After the injection method was changed to intermittent injection, the average emission of nitrogen oxides was 101.6mg / Nm³.

Embodiment 3

[0031] Embodiment 3: The method for reducing the emission of nitrogen oxides under low load of the boiler. The difference from Embodiment 2 is that the secondary air distribution method for combustion in the boiler is changed to: fully close the secondary air door 7 and fully open The average emission of nitrogen oxides is 78.7mg / Nm³ for the upper secondary damper 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com