Flue gas desulfurization and denitrification treatment device for tubular furnace

A technology for desulfurization, denitrification, and treatment devices, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve problems such as non-compliance with emission standards, and achieve the effects of easy structural design, low investment, and convenient manufacturing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

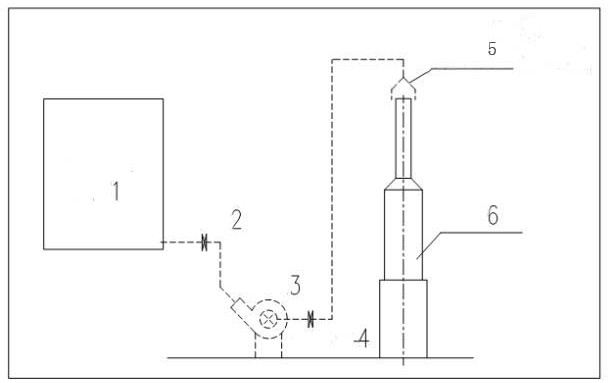

[0010] This device is composed of frequency conversion fan, frequency converter, pressure transmitter, automatic quick cut valve, flue gas collection cover, pipeline and so on. Make a gas collection hood and install it on the top of the chimney for flue gas collection; install a pressure transmitter on the top gas collection hood, and interlock the suction setting (-160Pa) with the fan operating frequency; install a fan on the ground , laying pipes to connect the gas collecting hood with the inlet of the fan, laying pipes at the outlet of the fan to connect the catalyst chamber of the desulfurization and denitrification system of the power plant; one automatic quick-cut valve is installed at the inlet and outlet of the fan, which is used for effective cut-off in the maintenance state. After the fan is turned on, the collected flue gas is sent to the desulfurization and denitrification system of the boiler in the power plant for treatment, and the treated flue gas meets the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com