Plastering, galling and automatic mortar-spraying machine

An automatic and spraying technology for ash brushing, which is applied in construction and building construction, etc., can solve problems such as inability to paint high walls, and achieve the effect of reducing labor amount, labor cost, and improving plastering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

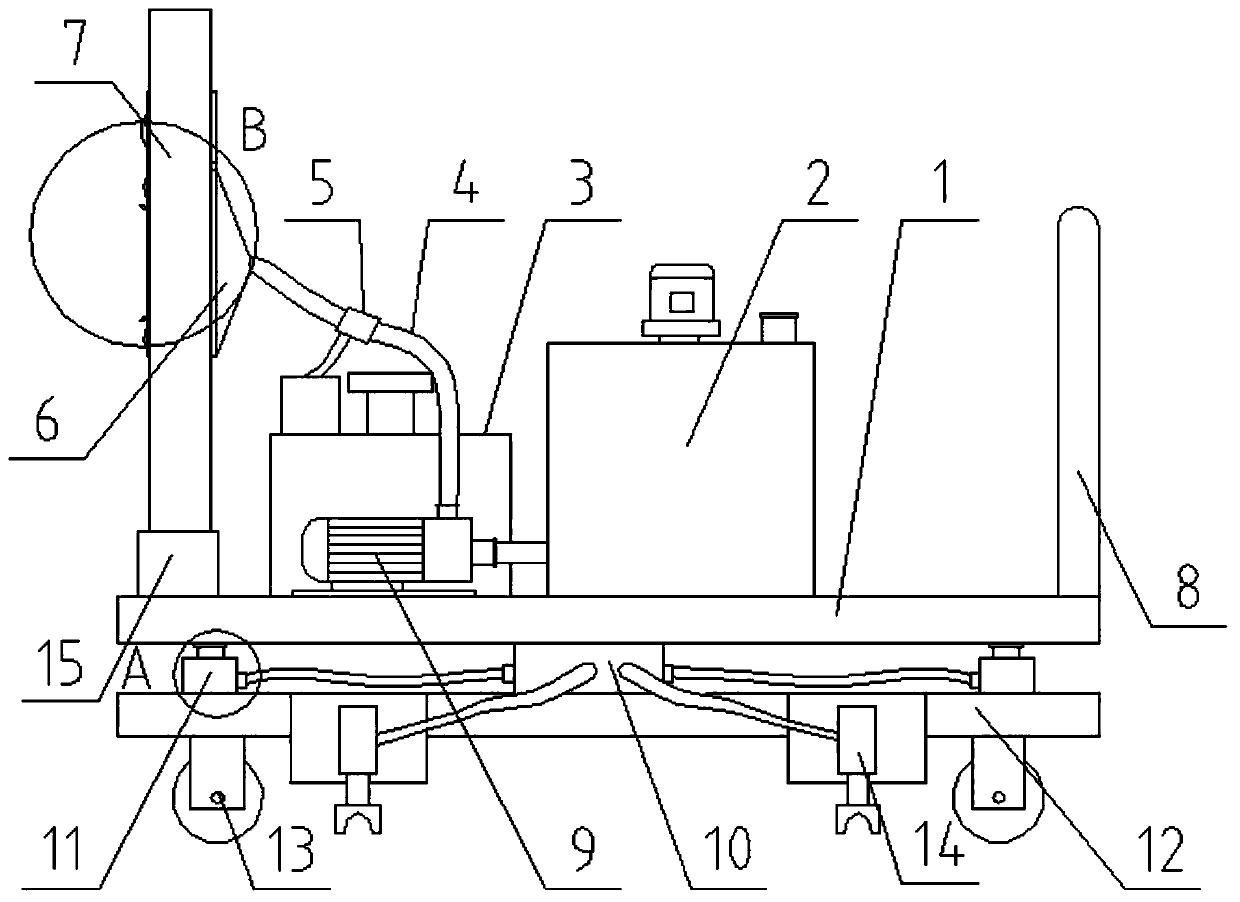

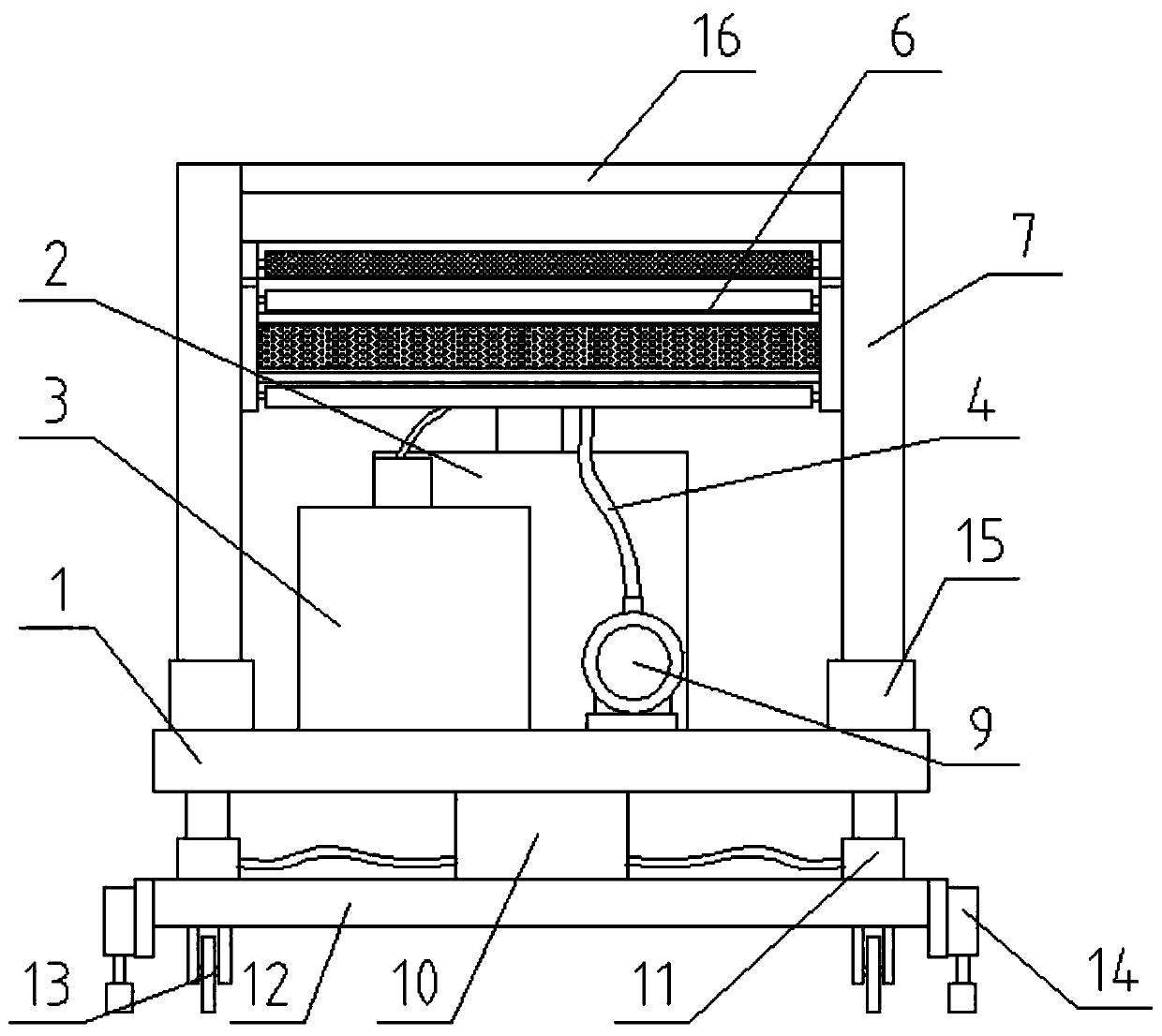

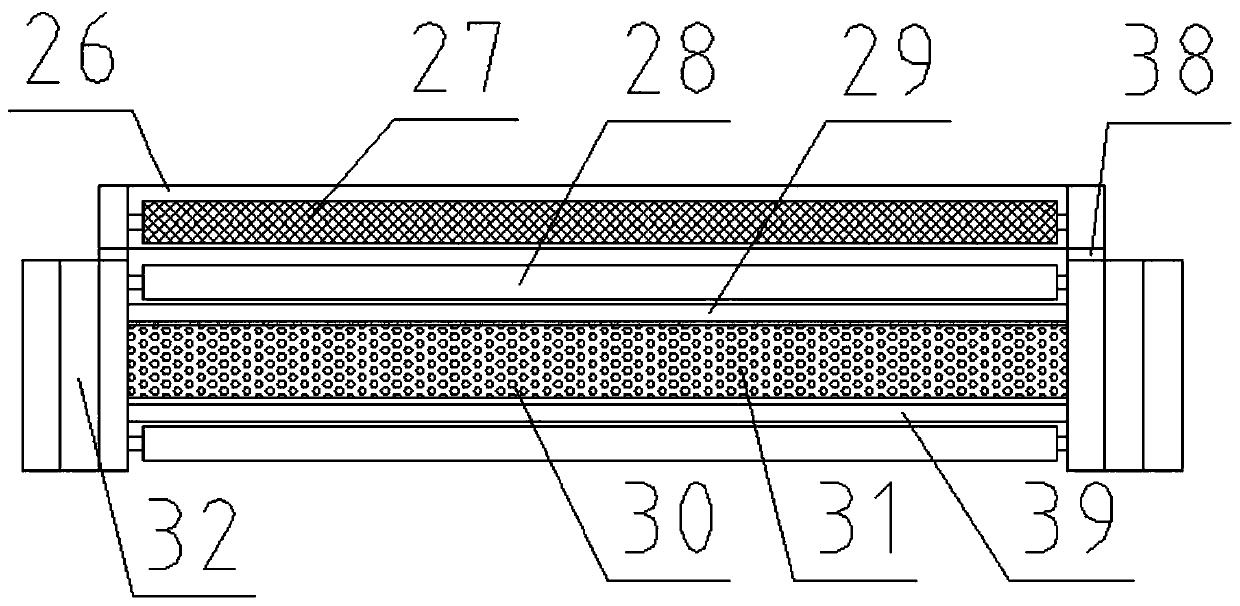

[0044] Such as Figure 1-10 As shown, a plastering and napping automatic spraying machine includes a base plate 1 and a base plate 12 located below the base plate 1, a hydraulic oil tank 10 is fixedly installed between the base plate 1 and the base plate 12 and is located at Four hydraulic jacking devices 11 at the four corners of the base plate 12, the base plate 1 and the base plate 12 are connected through four hydraulic jacking devices 11, and the four hydraulic jacking devices 11 all pass through the hydraulic oil tank 10 The oil guide pipe is connected, and the horizontal displacement mechanism 14 is symmetrically installed on the side of the base plate 12. The horizontal displacement mechanism 14 communicates with the hydraulic oil tank 10 through the oil guide pipe, and the four corners of the lower end of the base plate 12 are equipped with rollers 13.

[0045] The upper surface of the base plate 1 is fixedly equipped with a push-pull handle 8, a slurry storage box 2,...

Embodiment 2

[0052] Such as Figure 12 As shown, in this embodiment, on the basis of Embodiment 1, a handle cover 43 is fixedly installed on the push-pull handle 8, and a finger groove is provided on the handle cover 43, which is beneficial to promote the device to move more easily and conveniently. The constructor's hands provide some protection.

[0053] The rest of the structure and working principle of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0055] Such as Figure 13 As shown, in this embodiment, on the basis of Embodiment 1, a stirring motor 20 and a feed inlet 21 are fixedly installed on the top of the pulp storage box 2, and the output end of the stirring motor 20 extends downward to the interior of the pulp storage box 2 And the stirring rod 19 is coaxially connected, which is beneficial to drive the stirring rod 19 to stir the slurry evenly through the stirring motor 20, so as to ensure the construction efficiency, and the feeding port 21 is convenient for putting in the slurry.

[0056] The rest of the structure and working principle of embodiment 3 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com