Wall plastering machine capable of assisting in travelling

A technology for assisting walking and wall plastering, which can be used in construction, building construction, etc., and can solve the problems of high labor intensity, cumbersome operation methods, and low plastering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

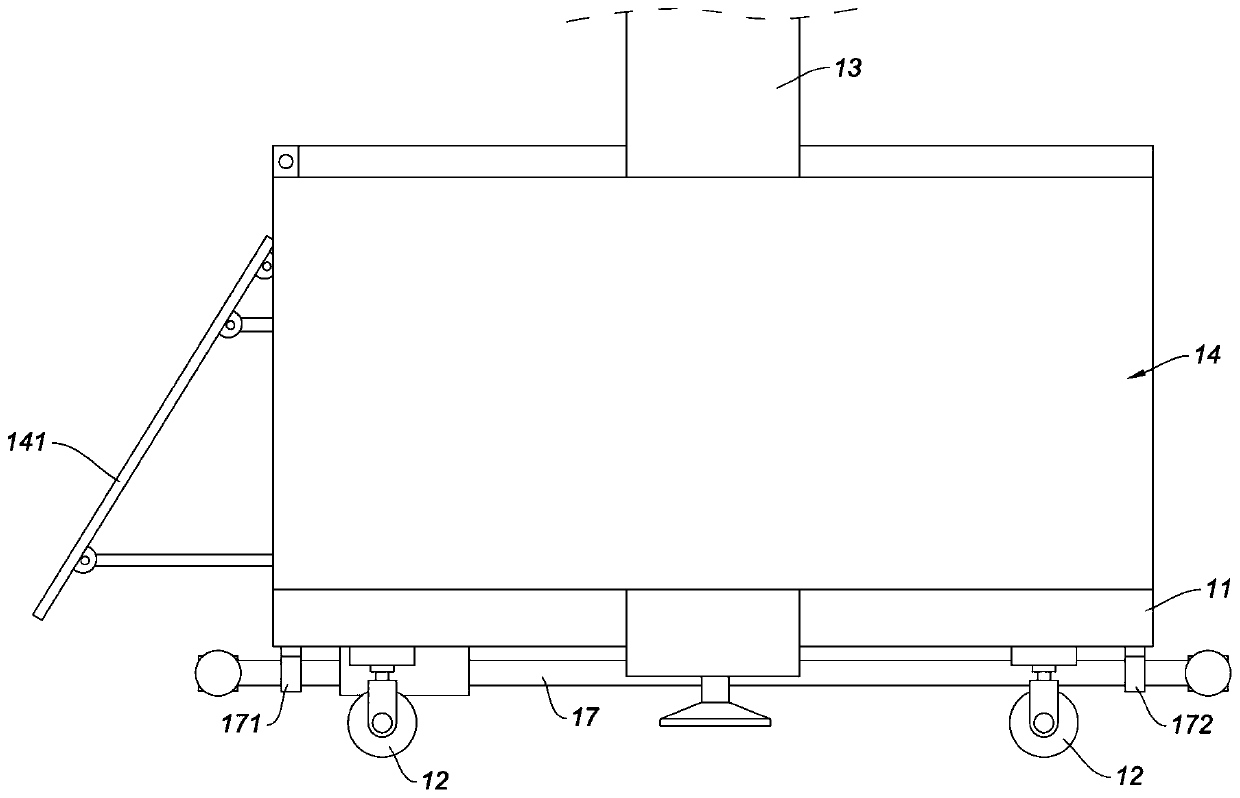

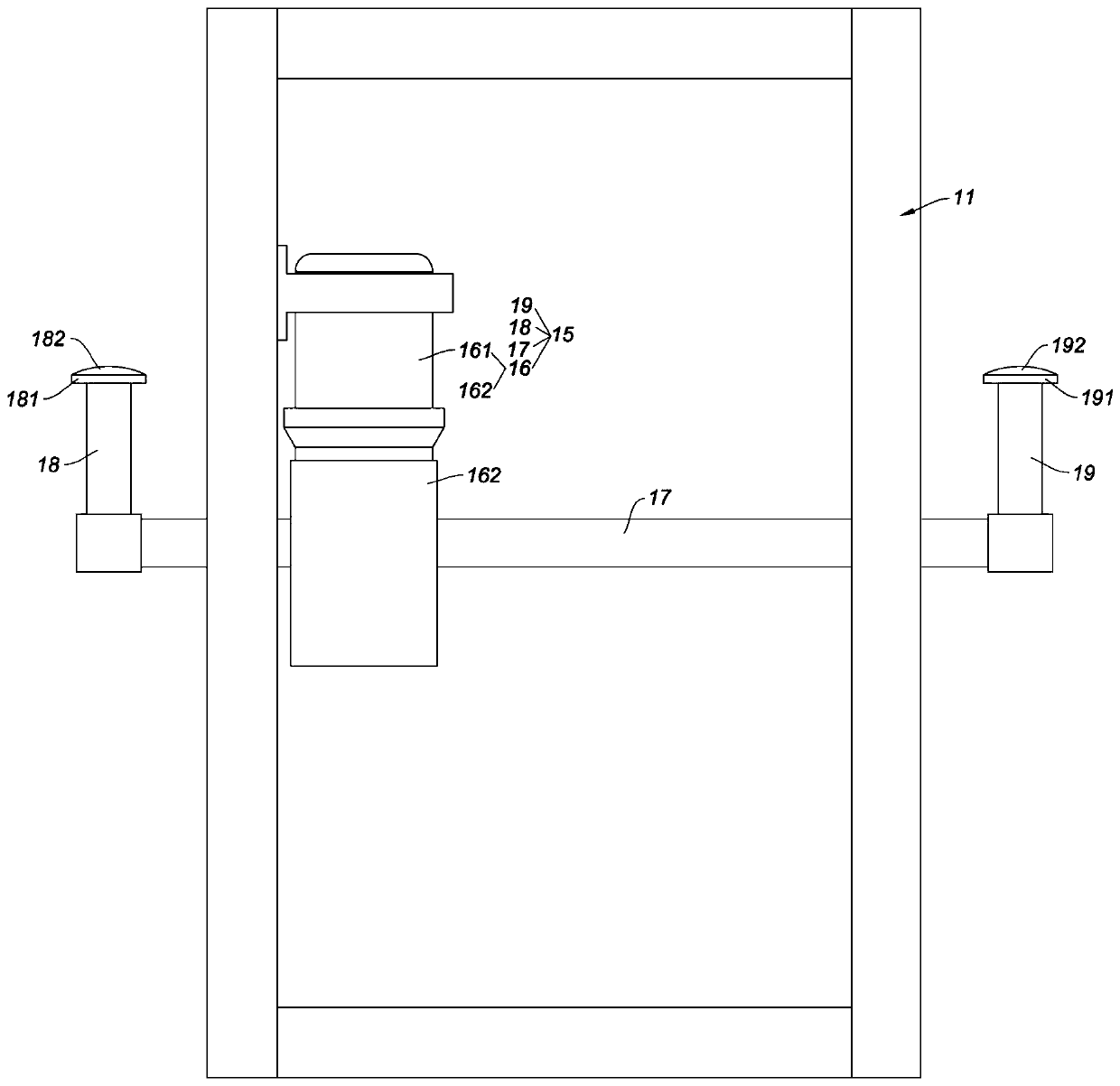

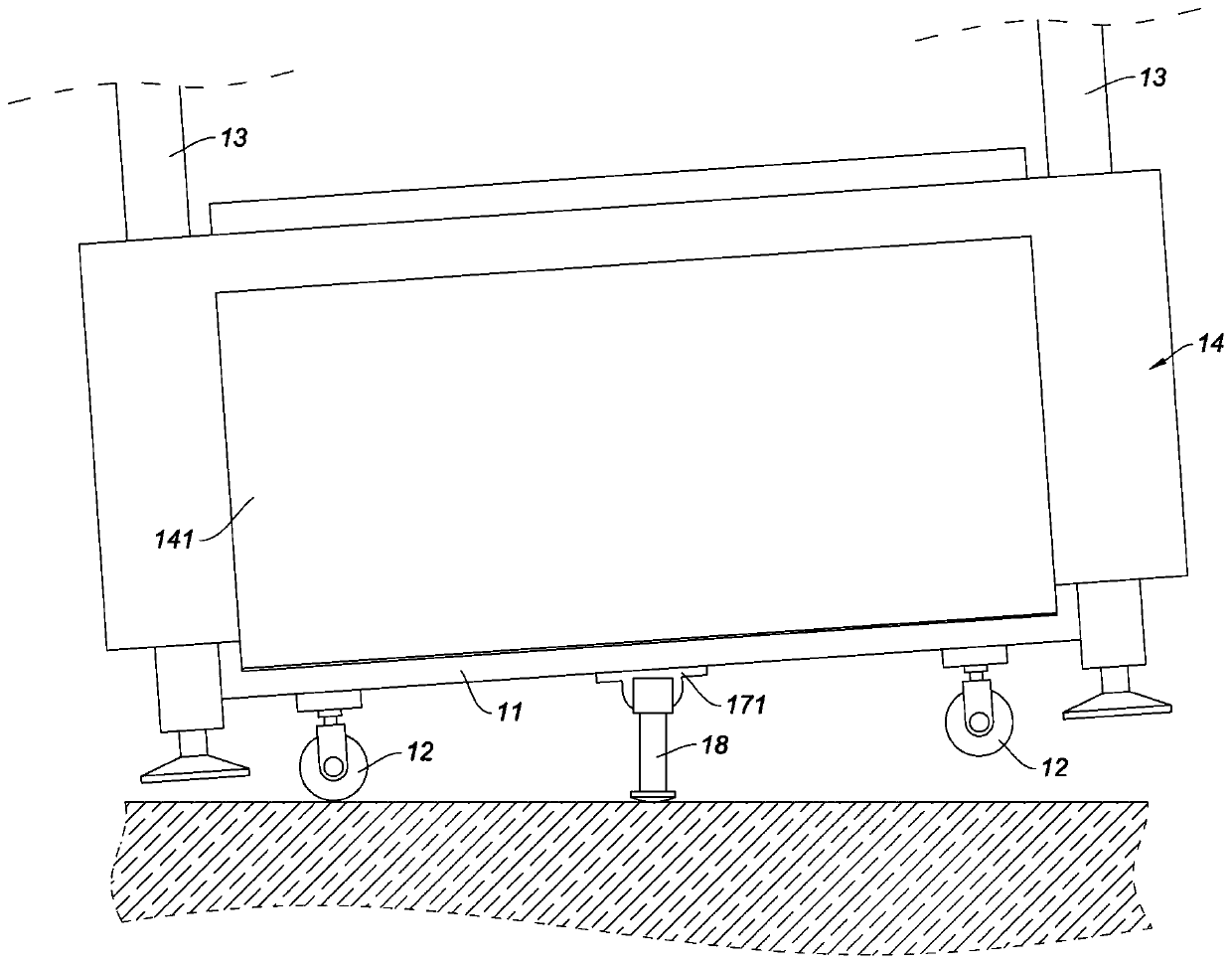

[0032] Such as figure 1 , figure 2 , image 3As shown, the present embodiment is a wall plastering machine that can assist walking, including a chassis 11, an upright rail 13 and a plastering main frame 14, the upright rail 13 is installed on the bottom frame 11, and the plastering main frame 14 is installed on an upright on the track 13, and the plastering host 14 can move up and down along the upright track 13; universal traveling wheels 12 are also installed on the underframe 11, specifically the four bottom corners of the underframe 11 are equipped with universal traveling wheels In order to realize the purpose of the wall plastering machine that can assist walking, the wall plastering machine that can assist walking also includes an auxiliary walking mechanism 15, and the auxiliary walking mechanism 15 includes a power unit 16, a rotating shaft 17, and a first floor support rod 18 and the second ground support rod 19; the rotating shaft 17 is rotatably installed on the...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is: as Figure 4 As shown, in this embodiment, two first ground support rods 22, 23 are installed at one end of the rotating shaft 21, and the two first ground support rods 22, 23 are evenly arranged around the axis of the rotating shaft 21. The first ground support rods 22, 23 are fixed on the rotating shaft 21; at the other end of the rotating shaft 21, 2 second ground support rods 24, 25 are installed, and the 2 second ground support rods 24, 25 also wrap around The shaft centers of the rotating shaft 21 are evenly arranged, and the two second ground support rods 24, 25 are also fixed on the rotating shaft 21. Such a design makes the wall plastering machine, which can assist in walking, faster when walking, which is conducive to improving work efficiency.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is: as Figure 5 , Figure 6 As shown, one end of the rotating shaft 31 is provided with a first hub 311, and the other end of the rotating shaft 31 is provided with a second hub 314; the first ground support rod 32 is installed on the first hub 311, and the first support ground The rod 32 can be telescopically moved relative to the first hub 311. The structure of the first floor support rod 32 that can be telescopically moved relative to the first hub 311 is generally formed in the first hub 311 with a first movable cavity 312. A limiting ring portion 313 is formed on the edge of the opening of the first movable chamber 312, and one end of the first floor support rod 32 is inserted into the first movable chamber 312, and when the first floor support rod 32 is inserted into the first movable chamber 312 That end is formed with a big head 322 that is spaced with the limit ring portion 313, so that the first floor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com