Automatic injecting and pasting machine system for walls and ceilings and control method thereof

A plastering machine and automatic technology, applied in the direction of construction and building structure, can solve the problems of low degree of automation, easy mechanical failure, low plastering efficiency, etc., and achieve high degree of automation, simple and lightweight structure, and plastering efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

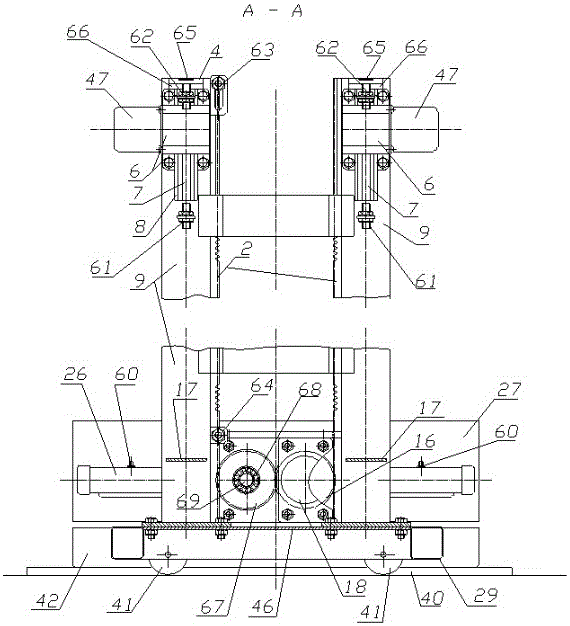

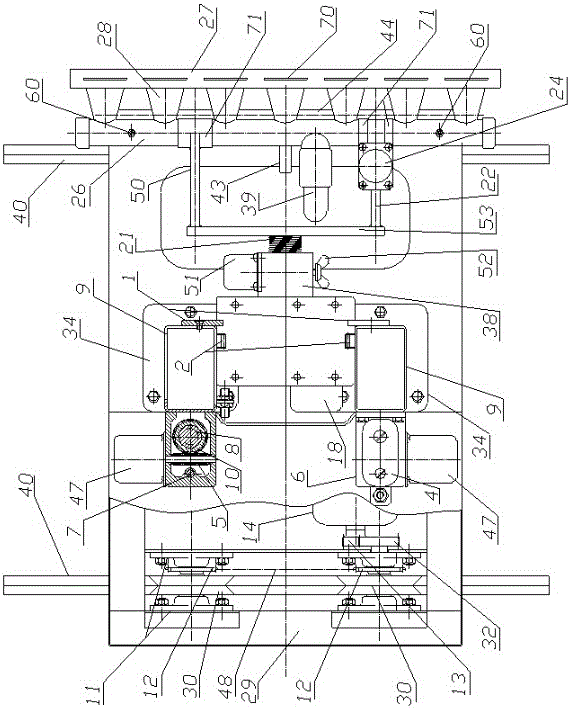

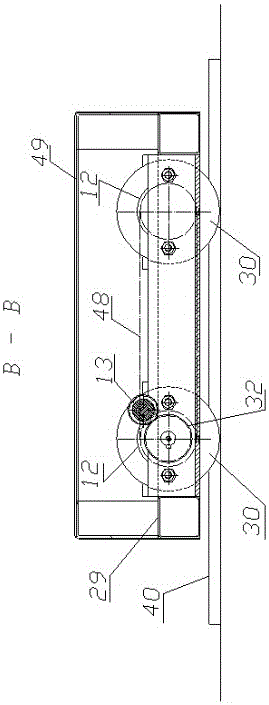

[0024] Such as Figure 1~Figure 8 As shown, it is a related structural diagram and system diagram of a specific embodiment of a wall ceiling automatic spraying and plastering machine system of the present invention. It includes a vertical lifting rod mechanism, a special plastering arm, an integrated ash storage tank for mixing pump ash, a horizontal walking trolley, an air compressor and a control circuit; the vertical lifting rod mechanism is composed of a pair of vertical lifting rods 9 and a lifting mechanism. A pair of vertical lift rods 9 are symmetrically provided with a pair of racks 2 along the vertical height direction on the inner outer wall opposite to each other, and a pair of guide rails 1 arranged symmetrically along the vertical height direction of the vertical lift rods 9 are closely attached to the right tube wall. The top of a pair of vertical elevating rods 9 is provided with the automatic locking positioning mechanism of the elevating rod, and the automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com