Plastering fillet and constructional plastering method

A technology of ash reinforcement and construction, which is applied in construction and building structure, etc., can solve the problems that plastering work is not suitable for large-area mechanized construction operations, it is difficult to ensure the overall height and flatness of the wall surface, and the construction steps are increased. The effect of shortening construction period, improving plastering efficiency and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

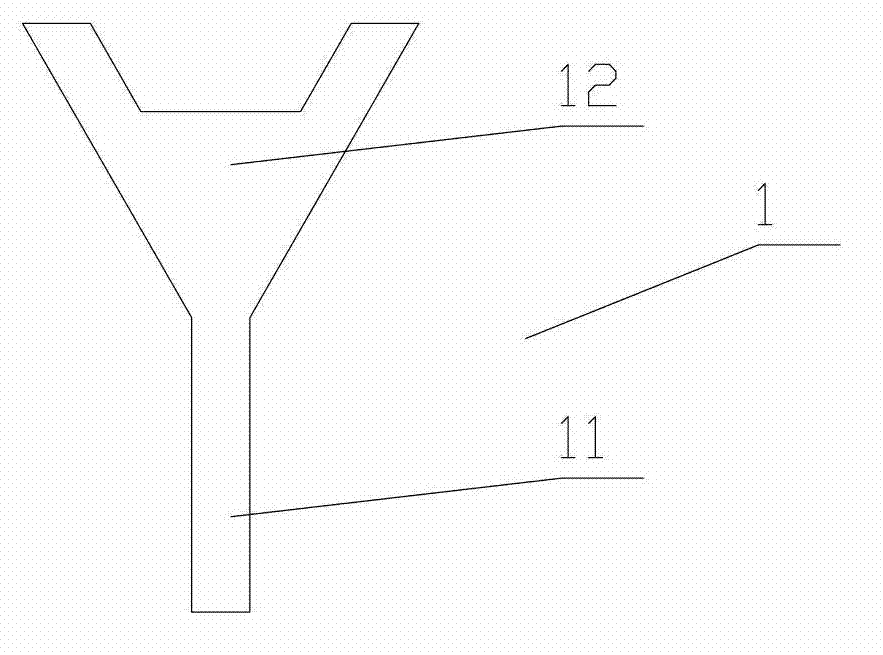

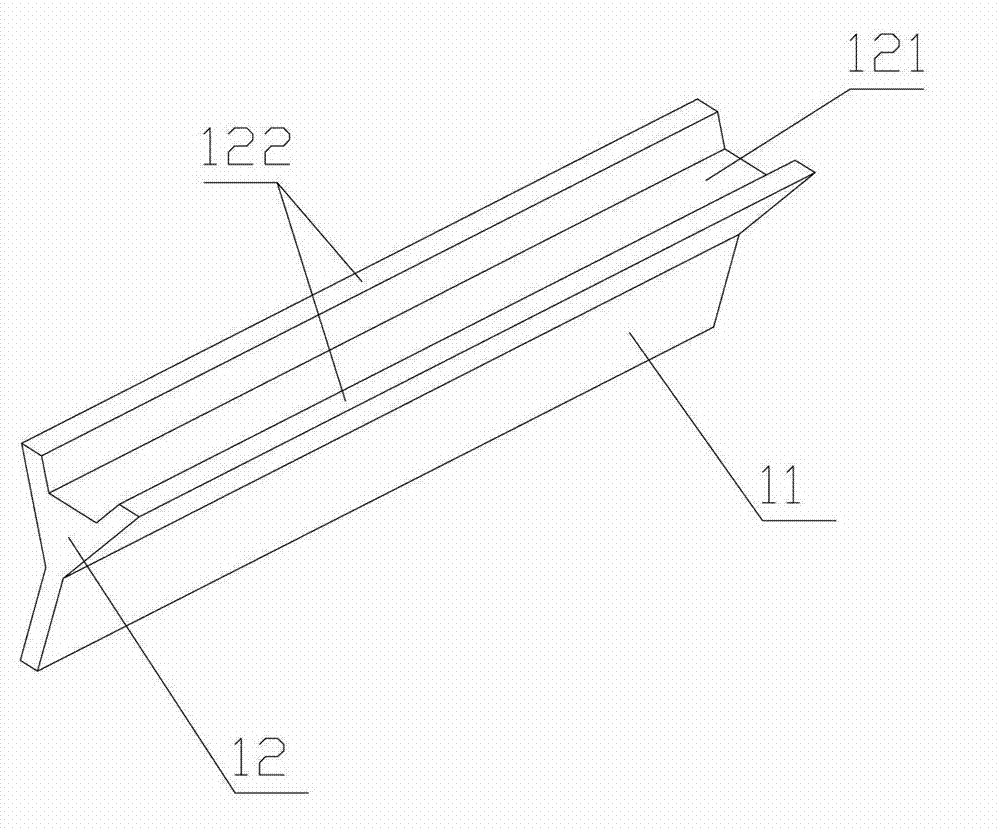

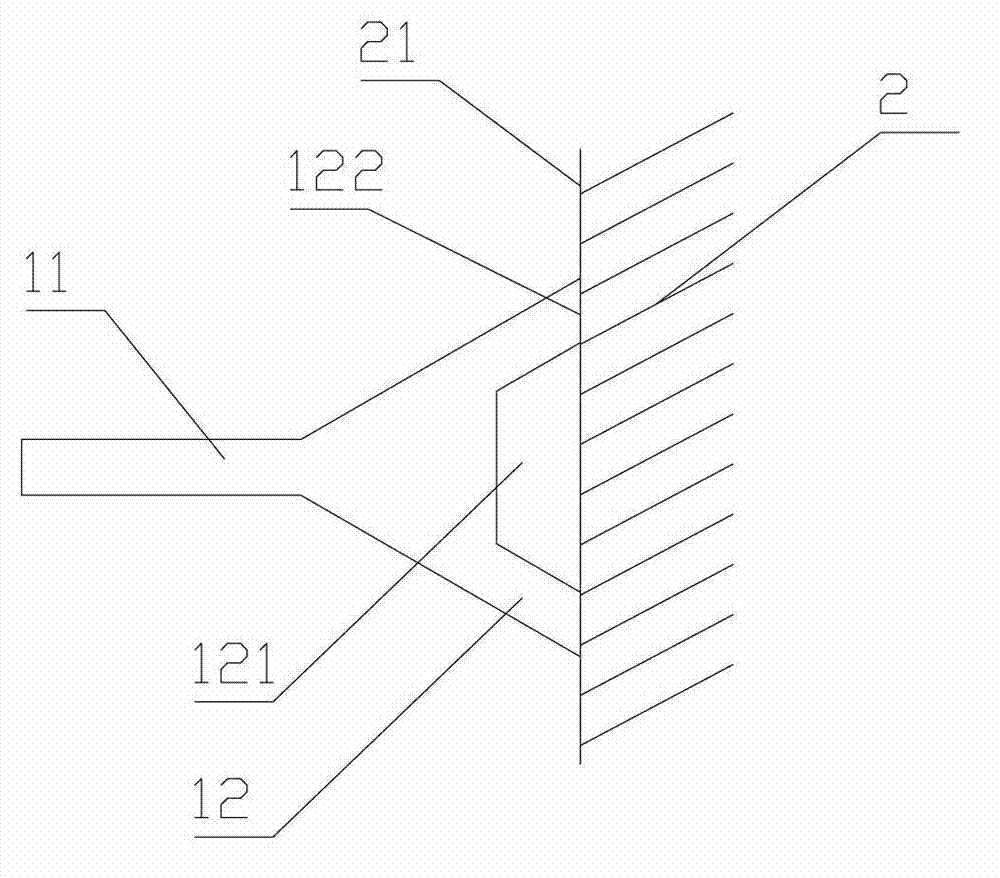

[0032] Such as Figure 1 to Figure 3As shown, a plastering tendon has a Y-shaped cross section and includes a fixed end 11 and a connecting end 12 arranged on the top of the fixed end 11. The connecting end 12 is provided with a groove 121, and the bottom of the groove 121 has a certain Width of the plane. In the present invention, the plastering ribs 1 are injection molded from a plastic material, which is a recyclable environmentally friendly plastic. Generally, it does not need to be removed after plastering, and it is directly adhered to the wall together with the mortar, which not only reduces the amount of plastering The construction steps will not affect the environment. Compared with the existing rib formwork, the plastering rib 1 does not need fixing holes or positioning holes, which not only ensures the strength of the plastering ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com