Plastering device for buildings

A technology for construction and plastering boards, which is applied in the direction of construction and building construction, and can solve the problems of easy blockage of pipelines, high requirements for feeding pumps, and heavy weight of mortar boxes, so as to avoid large bending and reliably transport mortar , the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

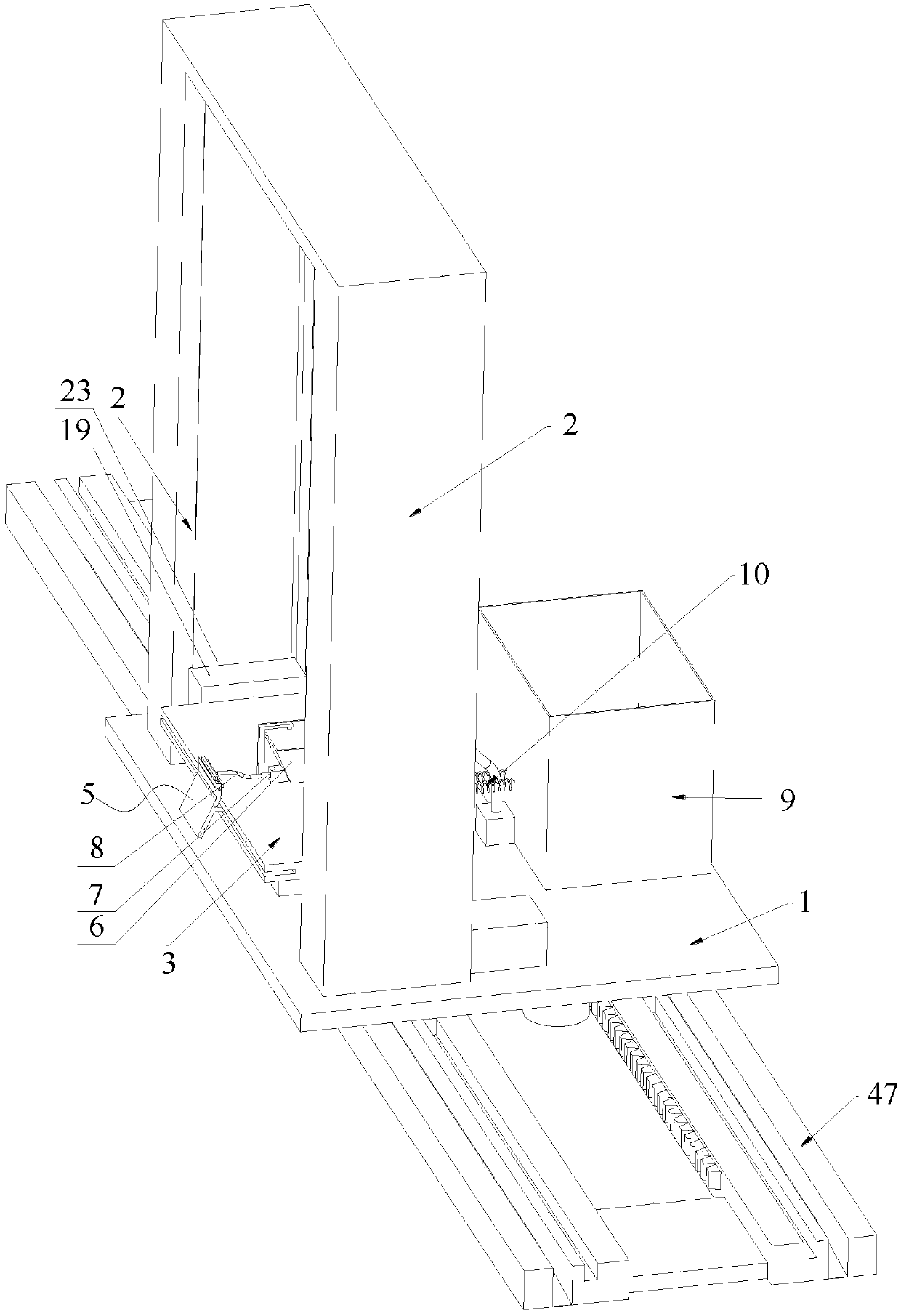

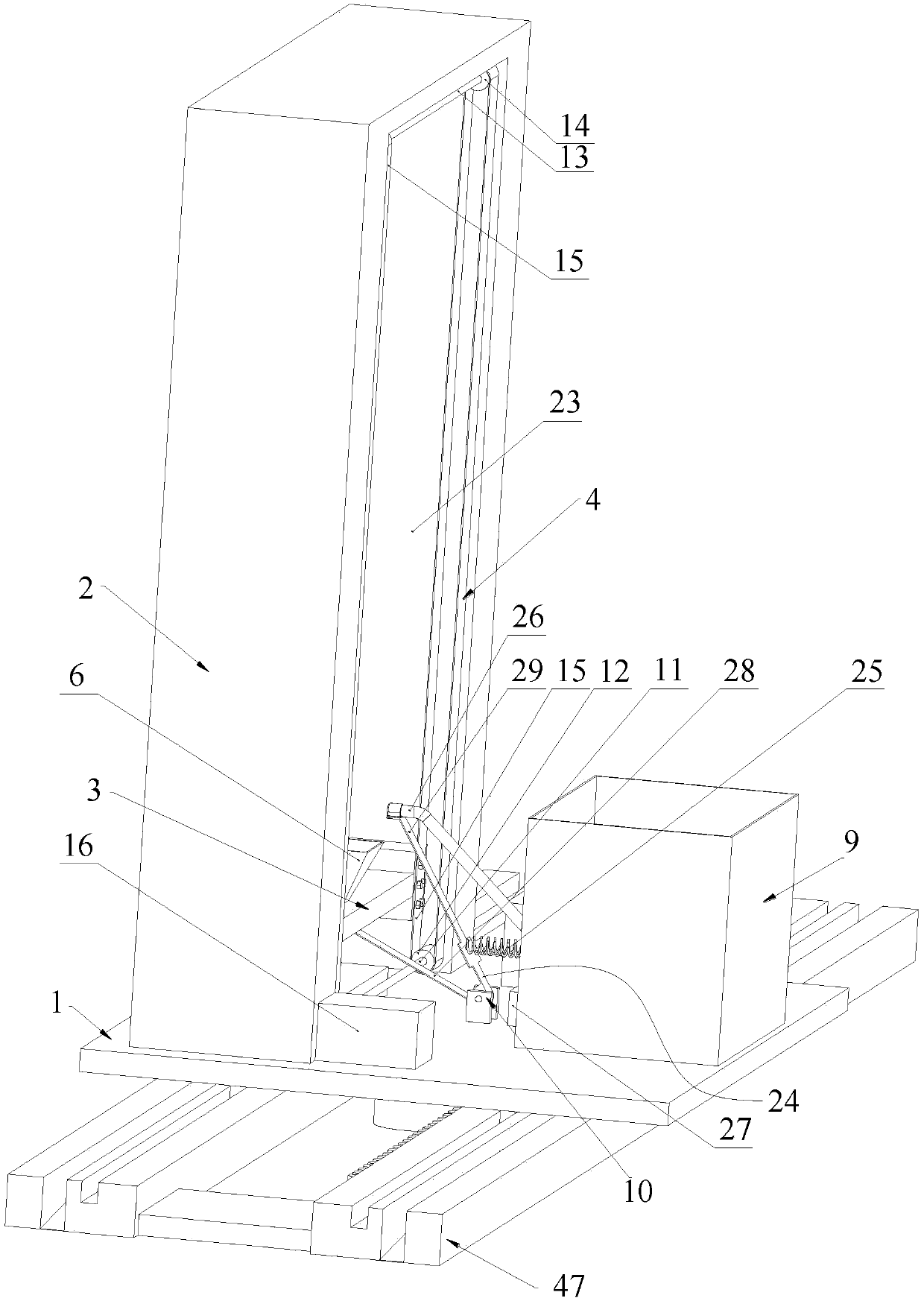

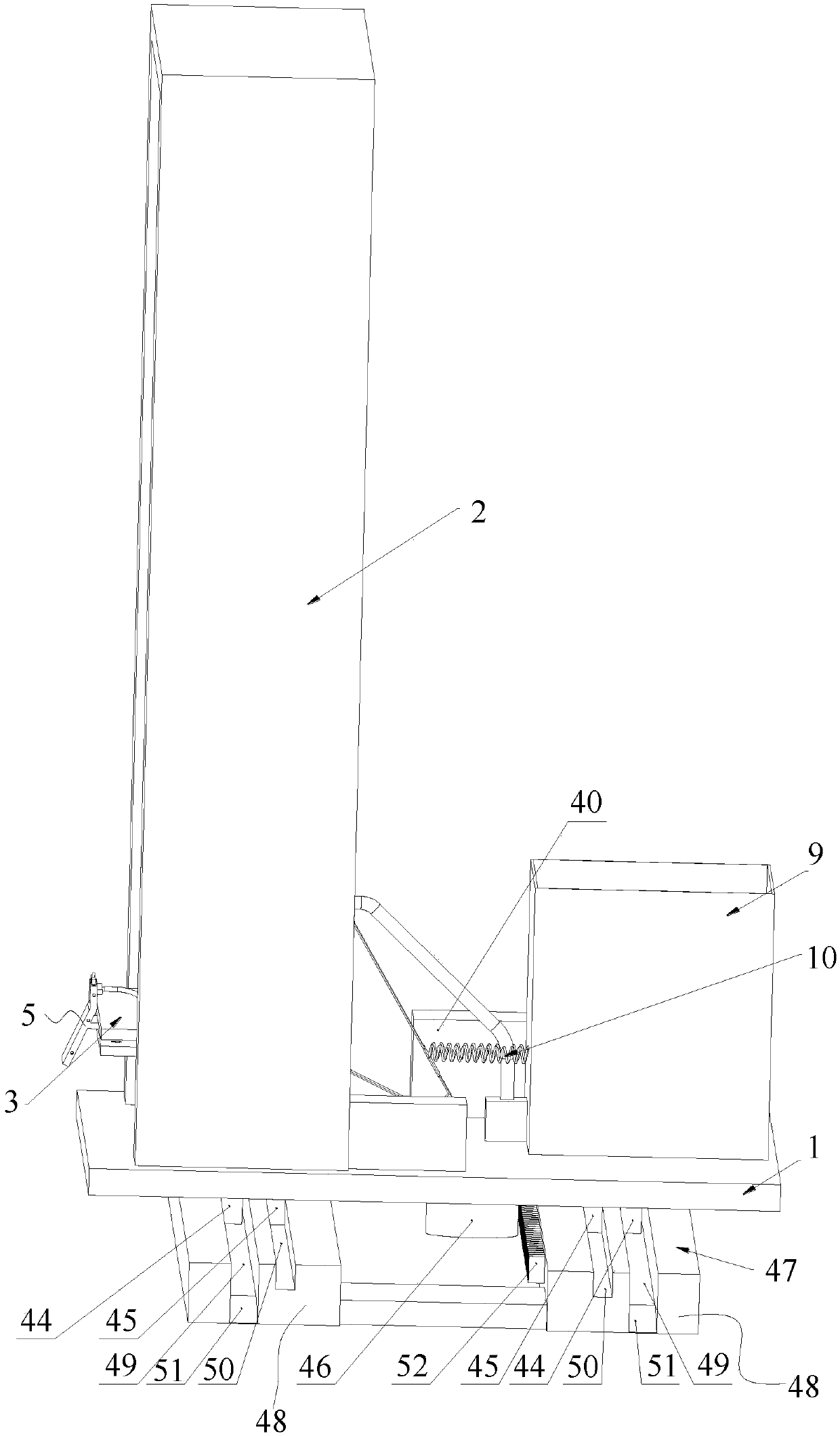

[0070] Such as figure 1 , 2 Shown in and 3, a kind of plastering device for building, comprises:

[0071] base1;

[0072] Two columns 2 are fixed on the base 1;

[0073] The lifting seat 3 is movable between the two columns 2 and can move up and down reciprocatingly;

[0074] The lifting mechanism 4 is used to drive the lifting seat 3 to reciprocate up and down;

[0075] Plastering board 5 is installed on the lifting seat 3;

[0076] The storage funnel 6 is fixed on the lifting seat 3 and is used to store the mortar;

[0077] The feed pump 7 is arranged at the lower part of the storage funnel 6, and is used to transport the mortar in the storage funnel 6 to the plastering board 5 through the first pipeline 8, so that the mortar is sprayed to the wall;

[0078] The mortar box 9 is fixed on the base 1;

[0079] The feeding mechanism 10 is used to transport the mortar in the mortar box 9 to the storage funnel 6 when the lifting base 3 is at the lowest position.

[0080] I...

Embodiment 2

[0112] Such as Figure 13 and 14As shown, the difference between this embodiment and Embodiment 1 is that there are multiple plastering boards 5 in this embodiment, and connecting pieces 57 are also included. , wherein the connecting column 58 of one plastering board 5 is inserted into the connecting groove 59 of the other plastering board 5, and the two ends of the connecting piece 57 are respectively fixed with two adjacent second threaded holes 54 by screws;

[0113] In the present embodiment, the quantity of the feeding pump 7 is the same as that of the plastering board 5, and the feeding pump 7 is used to convey mortar to the corresponding plastering board 5, and the storage funnel 6 has a feeding pump 7 that is connected to the storage funnel. Material funnel 6 cooperates. During actual use, when there are multiple storage funnels 6, the storage funnels 6 and the feeding pumps are matched one by one.

[0114] Through the cooperation of the horizontal groove 53, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com