Automatic plastering machine

A wall plastering machine and automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of large area of space that cannot be wiped, time-consuming, and cannot be promoted, and achieves high rigidity of the frame, high finish, and dust saving. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

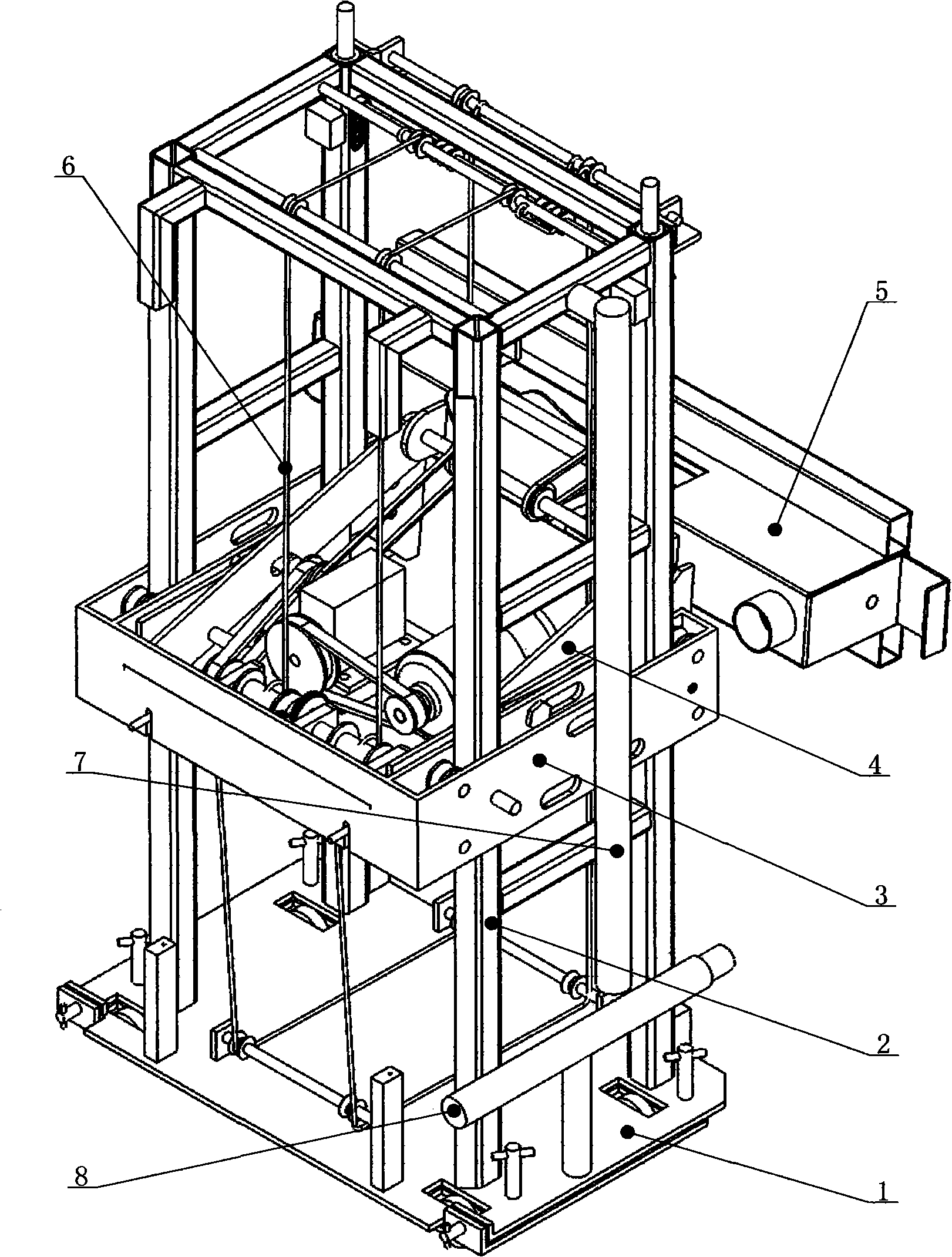

[0022] exist figure 1 middle:

[0023] The wall plastering machine consists of a base (1), a frame (2), a sliding sleeve (3), a power box (4), a plastering box (5), a steel wire rope (6), a verticality sensor (7), and a laser wall measuring instrument (8) Composition.

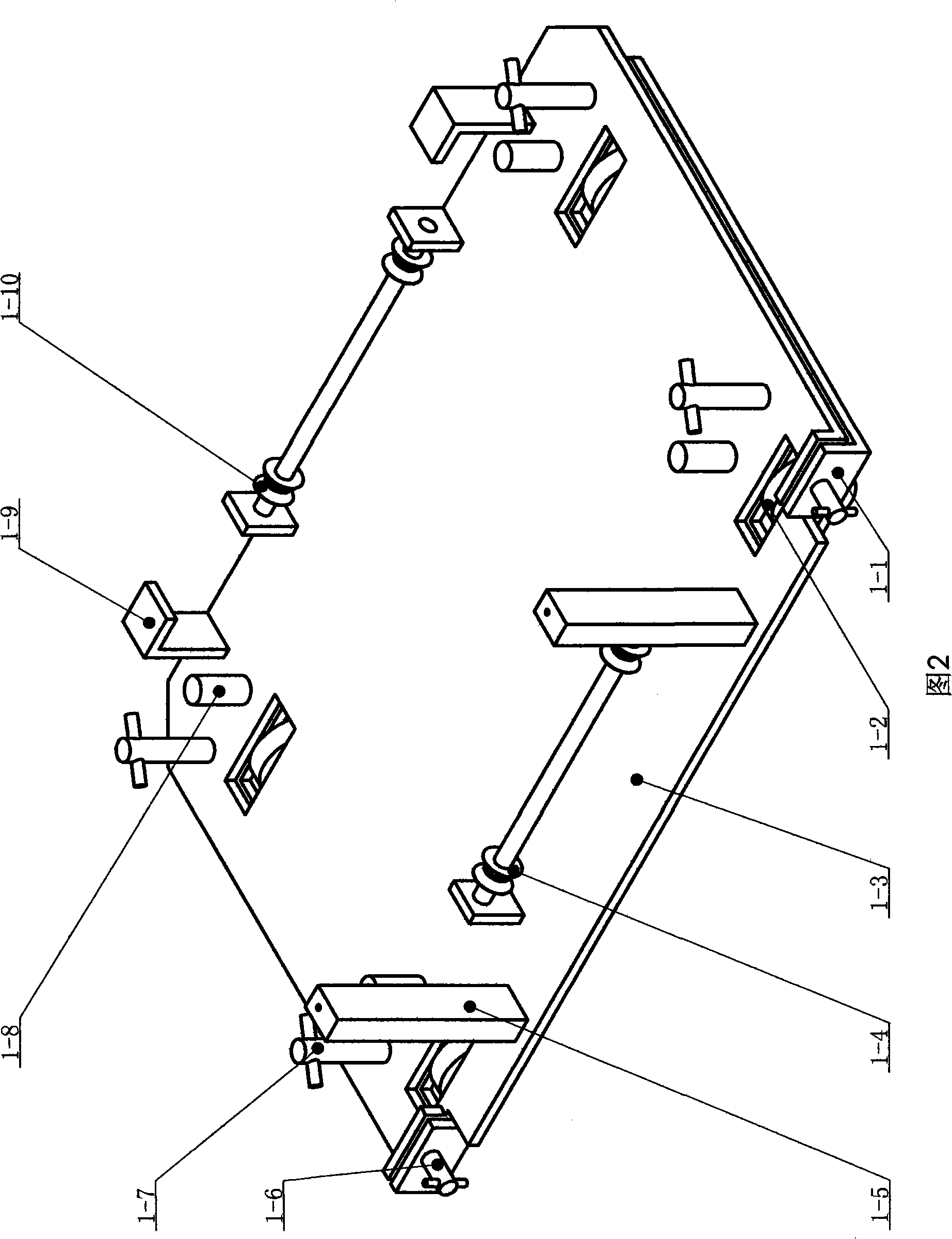

[0024] In Figure 2:

[0025] Base (1) is made of base plate (1-1), wheel (1-2), transition plate (1-3), fixed pulley 1 (1-4), lower positioning rod (1-5), horizontal adjustment rod (1 -6), vertical adjustment lever (1-7), positioning pin 1 (1-8), lower positioning plate (1-9), fixed pulley 2 (1-10) constitute. Wheels (1-2) are installed under the base plate (1-1). The transition plate (1-3) is placed on the base plate (1-1), and the transition plate (1-3) can perform horizontal displacement and angular displacement relative to the base plate (1-1). Fixed pulley 1 (1-4), lower positioning rod (1-5), horizontal adjustment rod (1-6), vertical adjustment rod (1-7), positioning pin (1-8), lower positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com