Flue plastering device and method

A technology for flue and plastering boards, which is applied in the direction of architecture and building construction, and can solve the problems of large volume of wall plastering devices, inapplicability to flue plastering, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

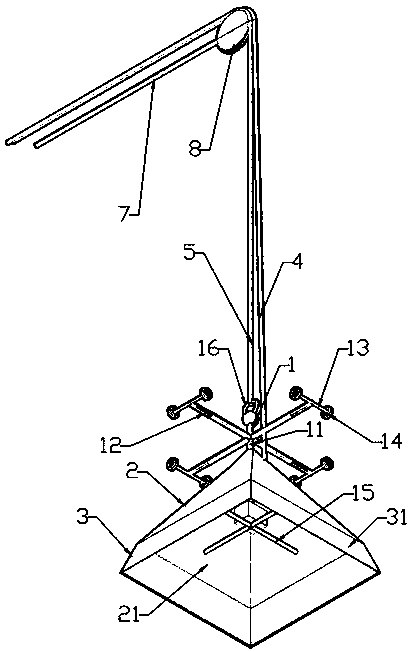

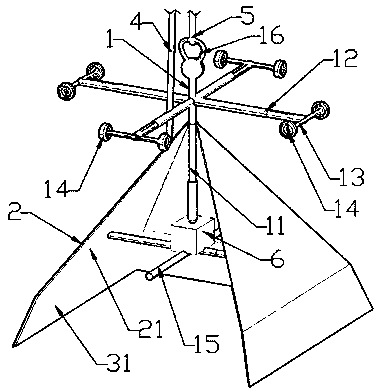

[0025] Such as figure 1 , figure 2 As shown, the flue plastering device provided in this embodiment includes a support frame 1 that can be supported on the inner wall of the flue and can slide up and down under the pull of an external force. The support frame 1 includes a vertical rod 11. The middle part of the rod 11 is covered with a hopper 2 coaxial with the vertical rod 11. The hopper 2 is funnel-shaped and is surrounded by four inclined plates 21 whose lower ends are all inclined outwards. A plastering board 31 is fixedly provided with a lower end inclined outwards, the length of each plastering board 31 is equal to the length of the lower end of the inclined board 21 connected to it, and the side ends of two adjacent plastering boards 31 are fixedly connected , forming a funnel-shaped plastering frame 3; a flexible concrete delivery pipe 4 is arranged at the upper end of the hopper 2, and the upper end of the flexible concrete delivery pipe 4 is fixed at the flue mouth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com