Commutator assembling machine and commutator assembling method thereof

A commutator and assembly machine technology, which is applied to assembly machines, metal processing, metal processing equipment, etc., can solve problems such as low assembly efficiency, low product yield, and poor installation accuracy of pole pieces, and achieve high assembly efficiency and compact size. small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing:

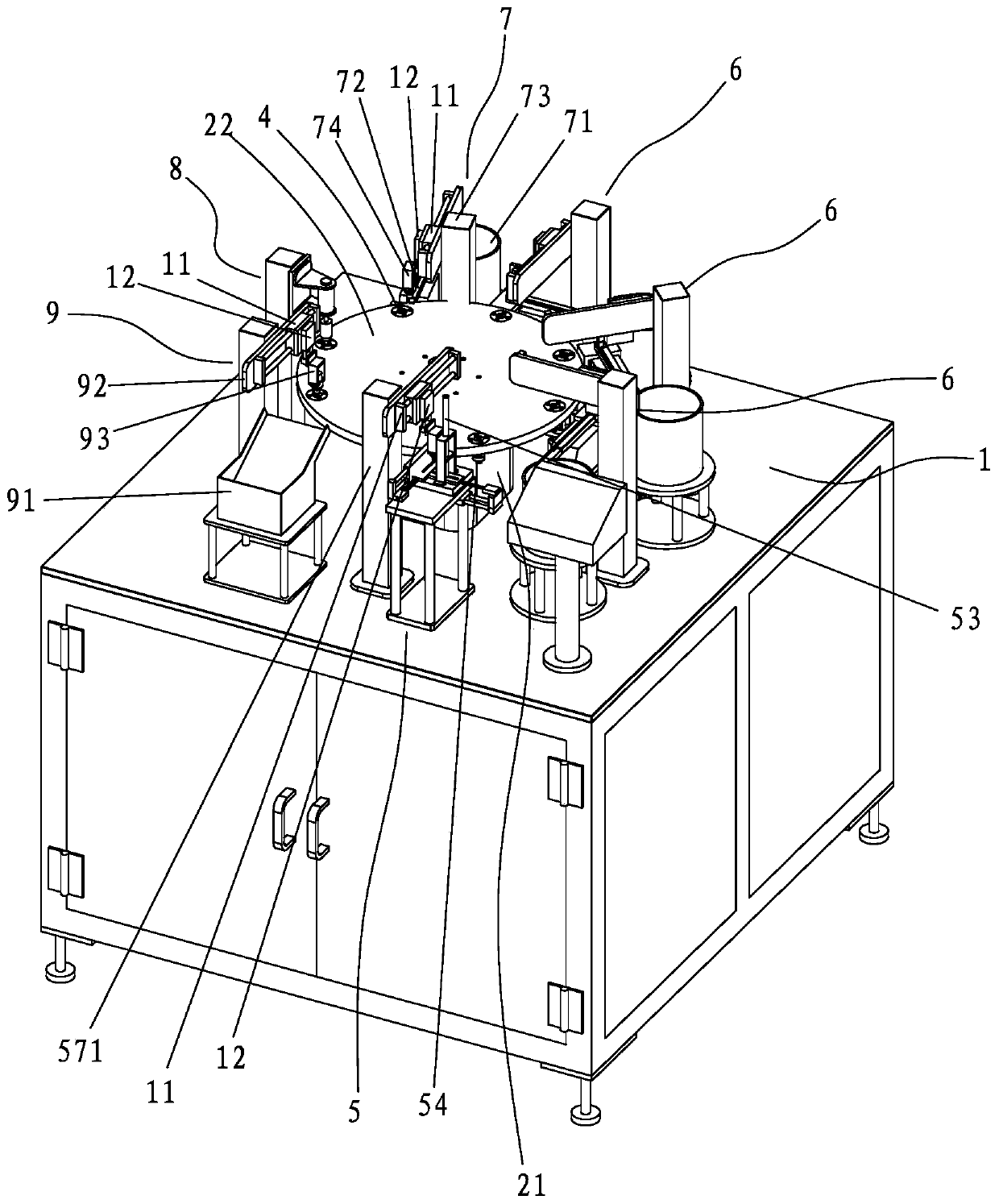

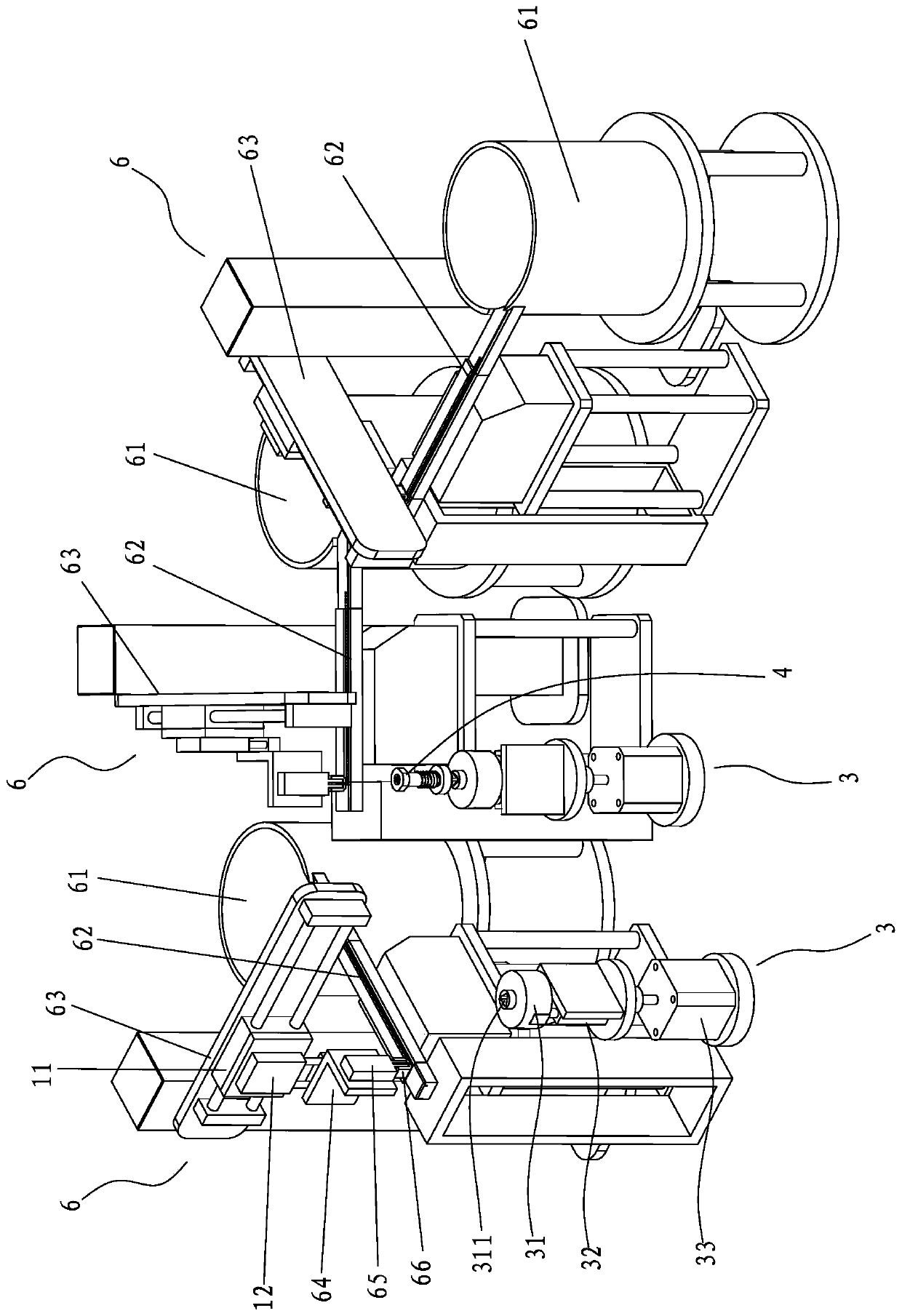

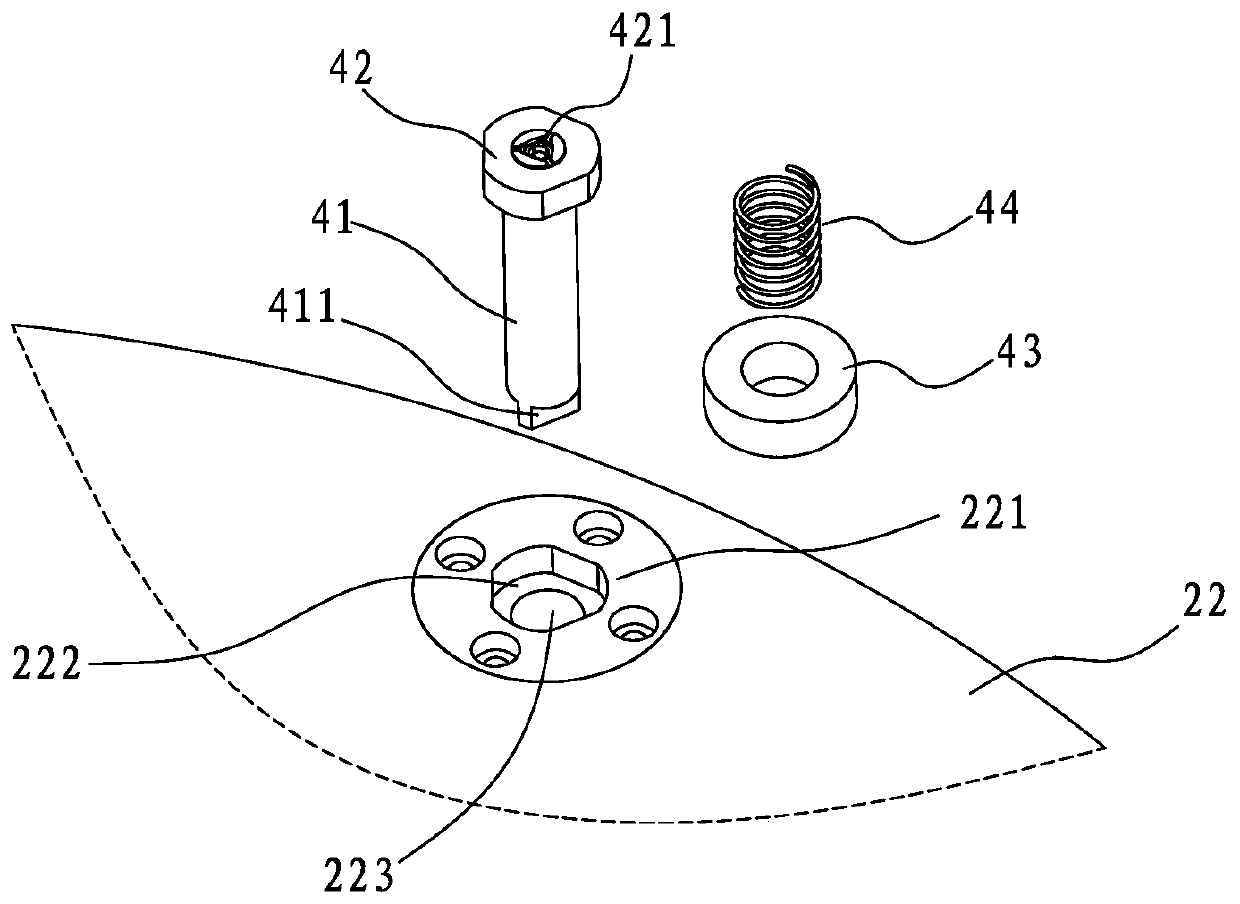

[0051] Such as Figure 1 to Figure 13 A commutator assembly machine shown includes an assembly platform 1, on which a divider 21 and a turntable 22 are arranged, and the divider 21 drives the turntable 22 to rotate intermittently, and the turntable 22 is arranged along the circumference A plurality of tooling 4 for clamping is evenly placed, and the assembly table 1 is located on the outer side of the turntable 22 along the circumference of the turntable 22, and is sequentially provided with a pressure ring feeding structure 5 and a plurality of pole piece feeding structures. Mechanism 6, skeleton feeding mechanism 7, skeleton pressing mechanism 8 and commutator unloading mechanism 9, the pressure ring feeding structure 5 is used to put the pressure ring 101 into the tooling 4, and a plurality of pole piece feeding The mechanism 6 is arranged from front to back around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com