Independent lifting mechanism and method of double-augmented stroke iron driller spinning wrench

A technology of independent lifting and stroke multiplication, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of reducing the efficiency of iron drillers in handling drilling tools, small adjustment of height and distance, affecting the efficiency of drilling work, etc., to improve the operation. Stability, smooth response, and the effect of improving positioning accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

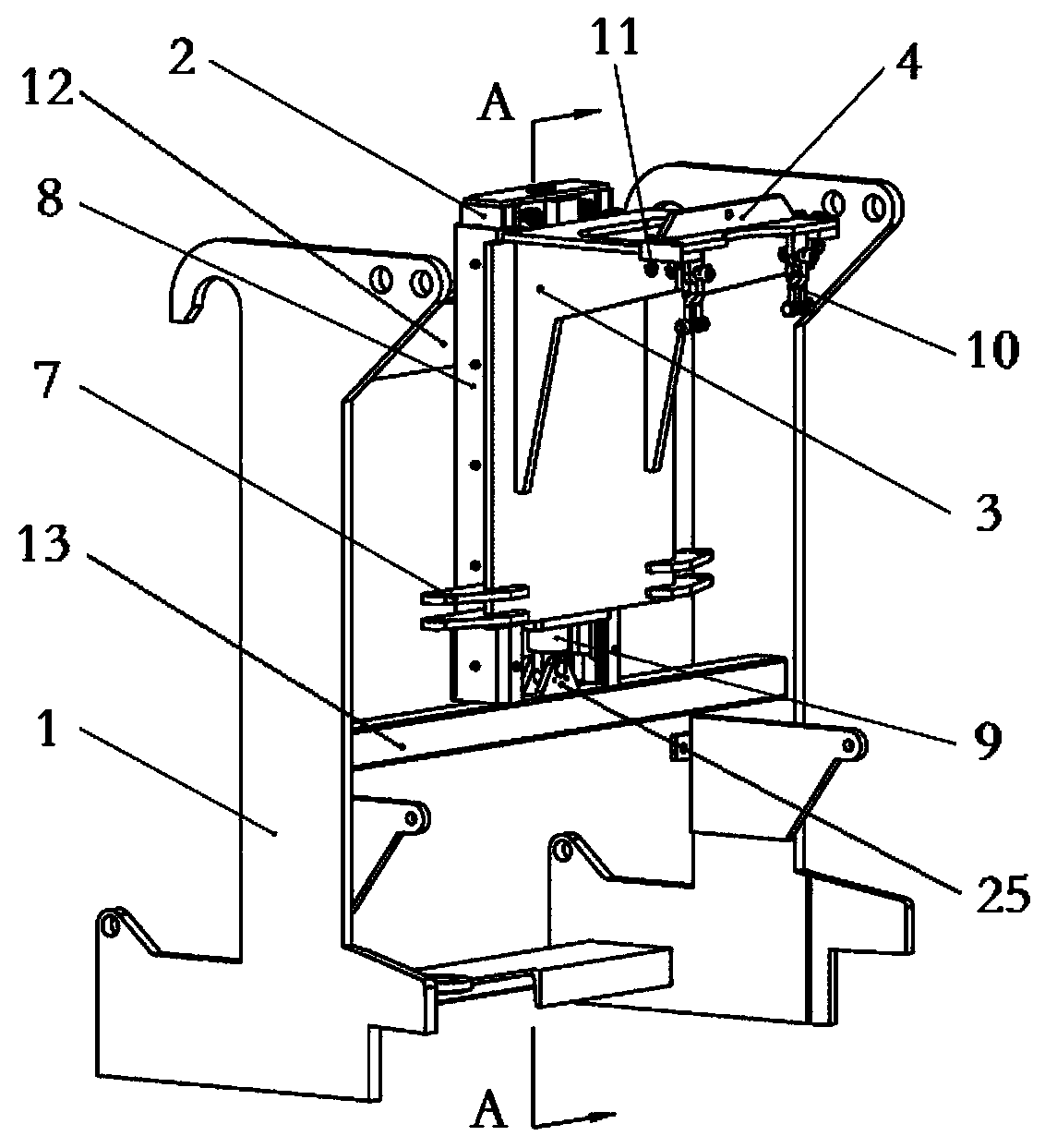

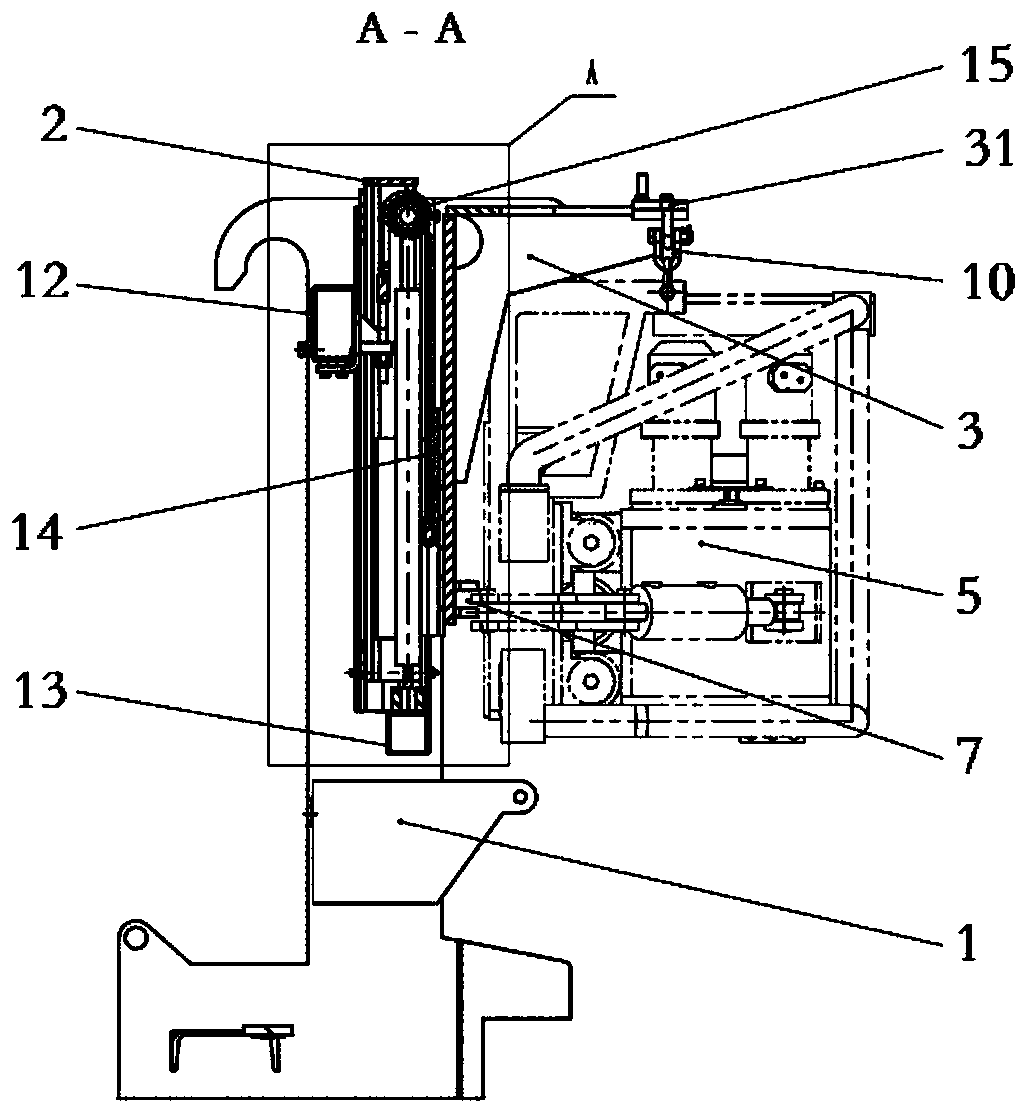

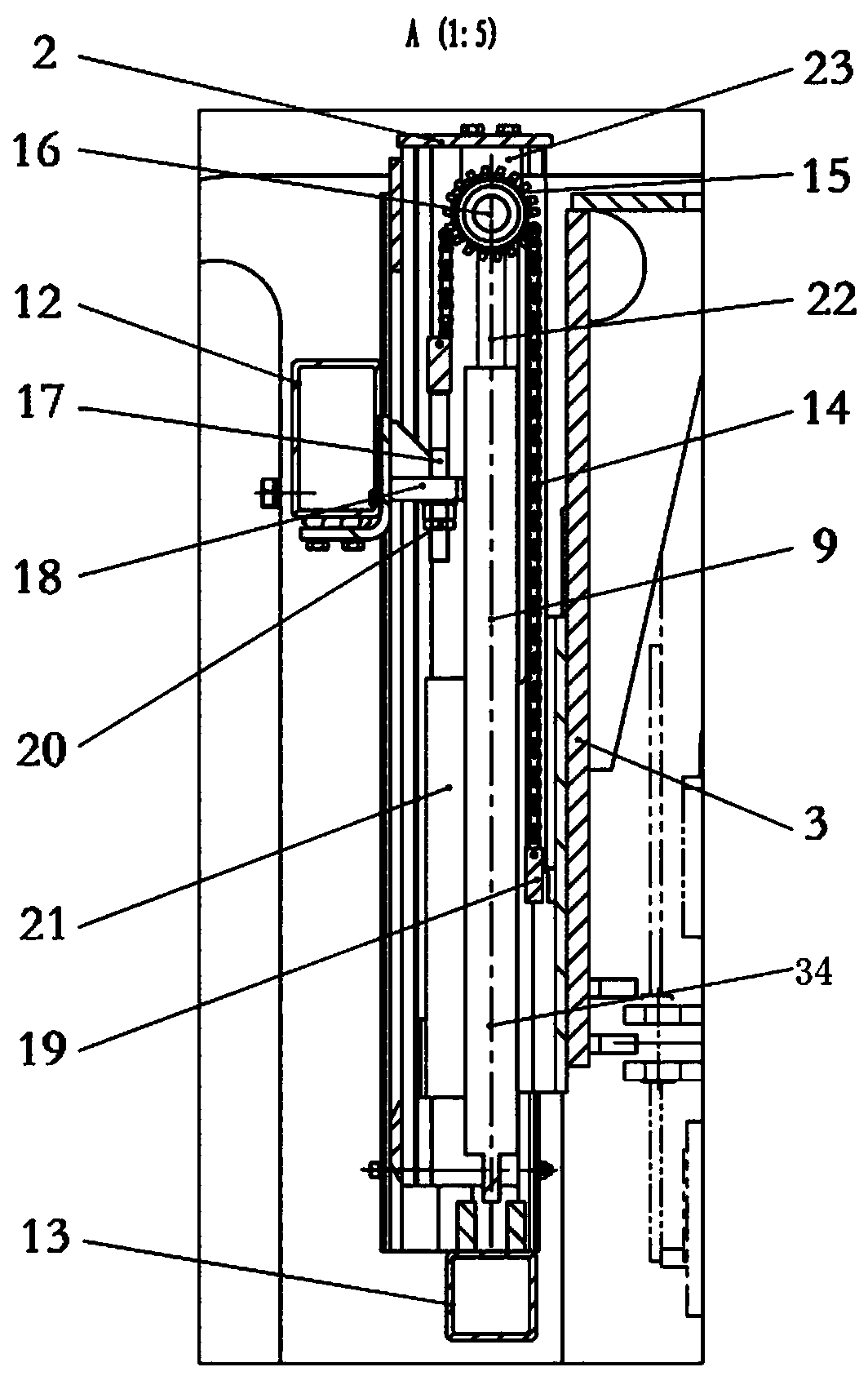

[0033] The present invention is an independent lifting mechanism of an iron driller's turnbuckle pliers capable of multiplying strokes, such as figure 1 and figure 2 As shown, it includes a frame body assembly 1, a guide body 2, a support frame assembly 3, a turnbuckle pliers assembly 5, a slider assembly 6, and the frame body assembly 1 includes a symmetrical and vertically arranged frame body 24 , the two frame bodies 24 are connected by the upper beam 12 and the lower beam 13 which are arranged up and down and horizontally, and two guide rails 8 are vertically connected between the upper beam 12 and the lower beam 13; The guide body 2, the guide body 2 can slide up and down along the guide rail 8, the guide body 2 includes a symmetrical and vertically arranged slide rail 26, such as Figure 5 As shown, the two slide rails 26 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com