Precise composite mold

A composite mold, sophisticated technology, applied in the direction of forming tools, manufacturing tools, decorative arts, etc., can solve the problem that the quality and style of handmade handicrafts cannot meet high requirements, it is difficult to reconcile the degree and structural strength of precious metals, and precious metal bowls are not beautiful, etc. problems, to achieve the effect of beautiful appearance, saving production costs, and reducing work procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

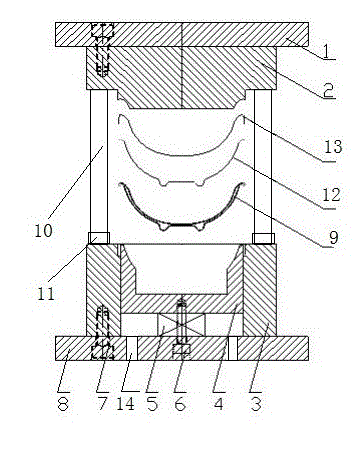

[0014] Such as figure 1 Shown, a kind of precision composite mould, comprises patrix, lower mold, printing bowl mold 9; Said patrix comprises upper fixed plate 1 and mold core 2 that are fixedly connected together, and wherein mold core 2 is convex font, mold The edge of the core 2 is set as a concave curved surface; the lower mold includes a mold ring 3, a binder positioning block 4, a binder spring 5, a bolt 6, a screw 7, and a lower fixing plate 8, wherein the mold ring 3 is fixed on the bottom by the screw 7. On the fixing plate 8, the binder positioning block 4 is arranged inside the die ring 3; The bolt section is equipped with a pressing spring 6; the printing bowl mold 9 is arranged in the pressing positioning block 4; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com