Automatic assembling device for automobile air conditioner radiator

An automatic assembly device and automobile air-conditioning technology, which is applied to vehicle parts, transportation and packaging, metal processing, etc., can solve problems such as inability to ensure flatness, improve work efficiency and production quality, reduce secondary placement procedures, and stabilize The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

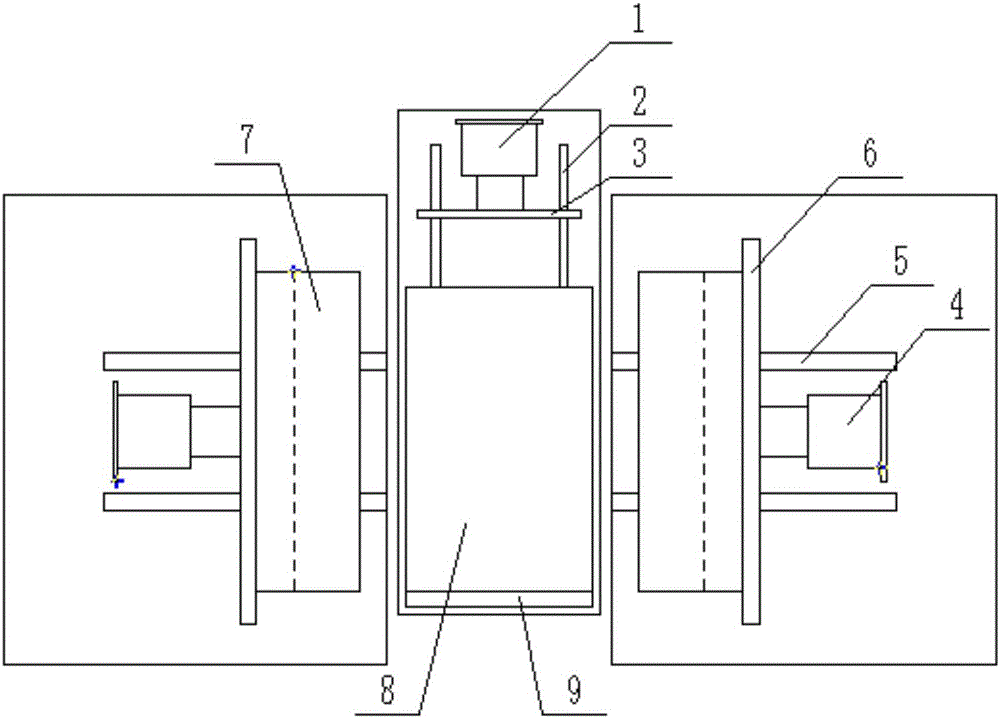

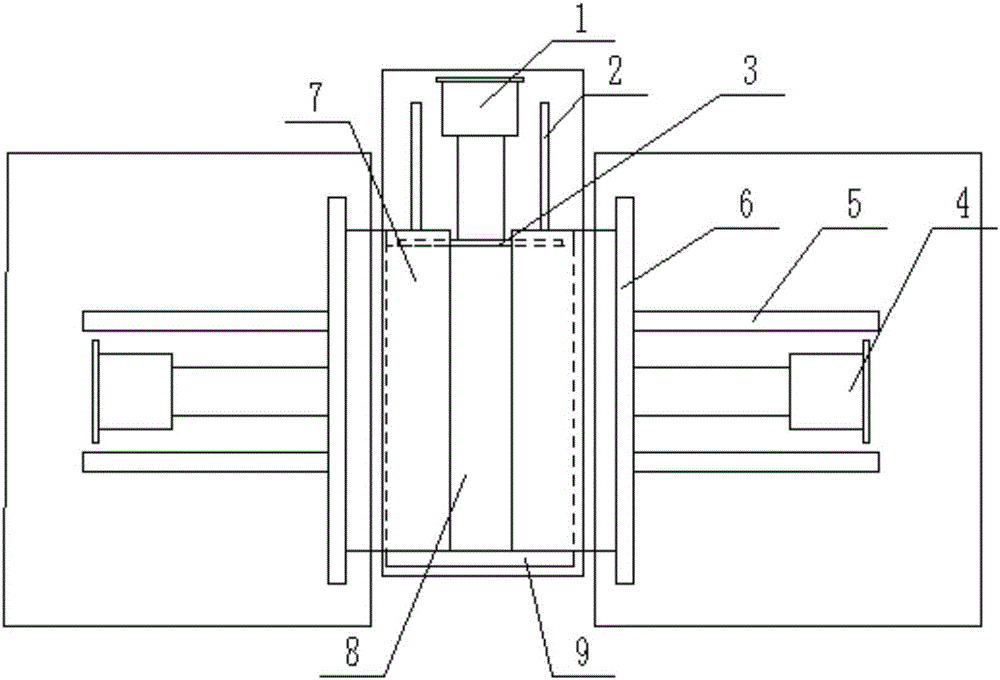

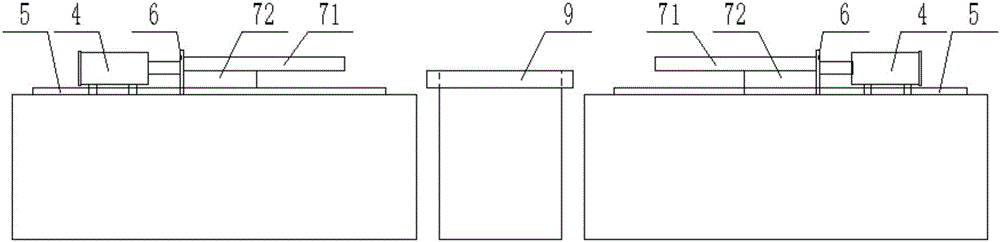

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings. Figure 1 to Figure 6 It is an embodiment of the present invention, as shown in the figure, including a first hydraulic cylinder 1, a first rail 2, a first baffle 3, a second hydraulic cylinder 4, a second rail 5, a second baffle 6, and a working platform 8 , the second hydraulic cylinder 4, the second track 5, and the second baffle 6 are evenly and symmetrically distributed on both sides of the working platform 8, and the front section of the second baffle 6 is fixed with a clamping unit 7, and the clamping unit 7 It includes a pressing plate 71 and a clamping groove 72. The length of the pressing plate 71 is longer than that of the clamping groove 72. The pressing plate 71 is movably linked with the clamping groove 72. The side of the working platform 8 away from the first hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com