Device for detecting sealing property of multi-cavity container or multiple containers by helium

A container sealing and container technology, which is applied in the field of leak detection devices for pressure vessels, can solve problems such as time-consuming and cumbersome work, and achieve the effects of reducing work procedures, improving work efficiency and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

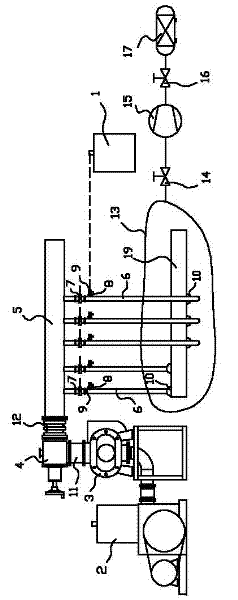

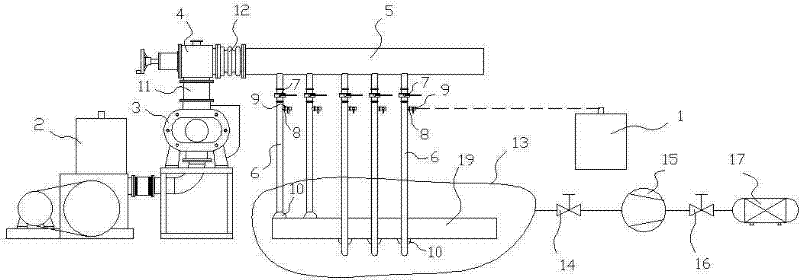

[0018] Such as figure 1 As shown, the present invention is a device that uses helium to detect the tightness of the plate-fin heat exchanger 19. The plate-fin heat exchanger 19 has five chambers (or channels). The present invention includes a helium mass spectrometer A leak detector 1, a vacuum slide valve pump 2, a Roots pump 3, a high vacuum baffle valve 4 and a manifold 5 connected in sequence, and a transition is connected between the Roots pump 3 and the high vacuum baffle valve 4 Section 11, a bellows 12 is connected between the high vacuum baffle valve 4 and the manifold 5, and a sealing device that is used to seal the multi-chamber container or multiple containers to be tested and can be filled with helium, said The sealing device includes an air bag 13, and the air bag 13 is connected to the helium tank 17 through the valve FC14, the compressor 15 and the valve FD16 in turn, and five connecting pipelines 6 are arranged on the collecting pipe 5, each of the connecting ...

specific Embodiment approach 2

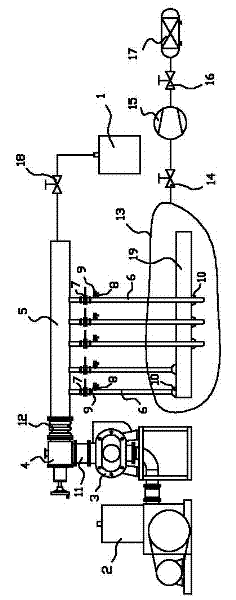

[0032] Such as figure 2 As shown, the present invention is a device that uses helium to detect the tightness of the plate-fin heat exchanger 19. The plate-fin heat exchanger 19 has five chambers, and the present invention includes sequentially connected vacuum slide valves Pump 2, Roots pump 3, high vacuum baffle valve 4, manifold 5, valve FE18 and helium mass spectrometer leak detector 1, a transition section 11 is connected between the Roots pump 3 and high vacuum baffle valve 4 , a bellows 12 is connected between the high vacuum baffle valve 4 and the manifold 5, and a sealing device that is used to seal the multi-chamber container or multiple containers to be tested and can be filled with helium, the sealing device Including an airbag 13, the airbag 13 is connected to the helium tank 17 through the valve FC14, the compressor 15 and the valve FD16 in sequence, and five connecting pipelines 6 are arranged on the collecting pipe 5, each of the connecting pipelines 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com