Device for adaptive control of ground clearance of front discharge door of pavement milling machine

An automatic control device, the technology of the height above the ground, which is applied in the control, road, road and other directions without feedback, to avoid the friction damage of the conveyor belt and the ground, prolong the service life, and achieve the effect of high control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

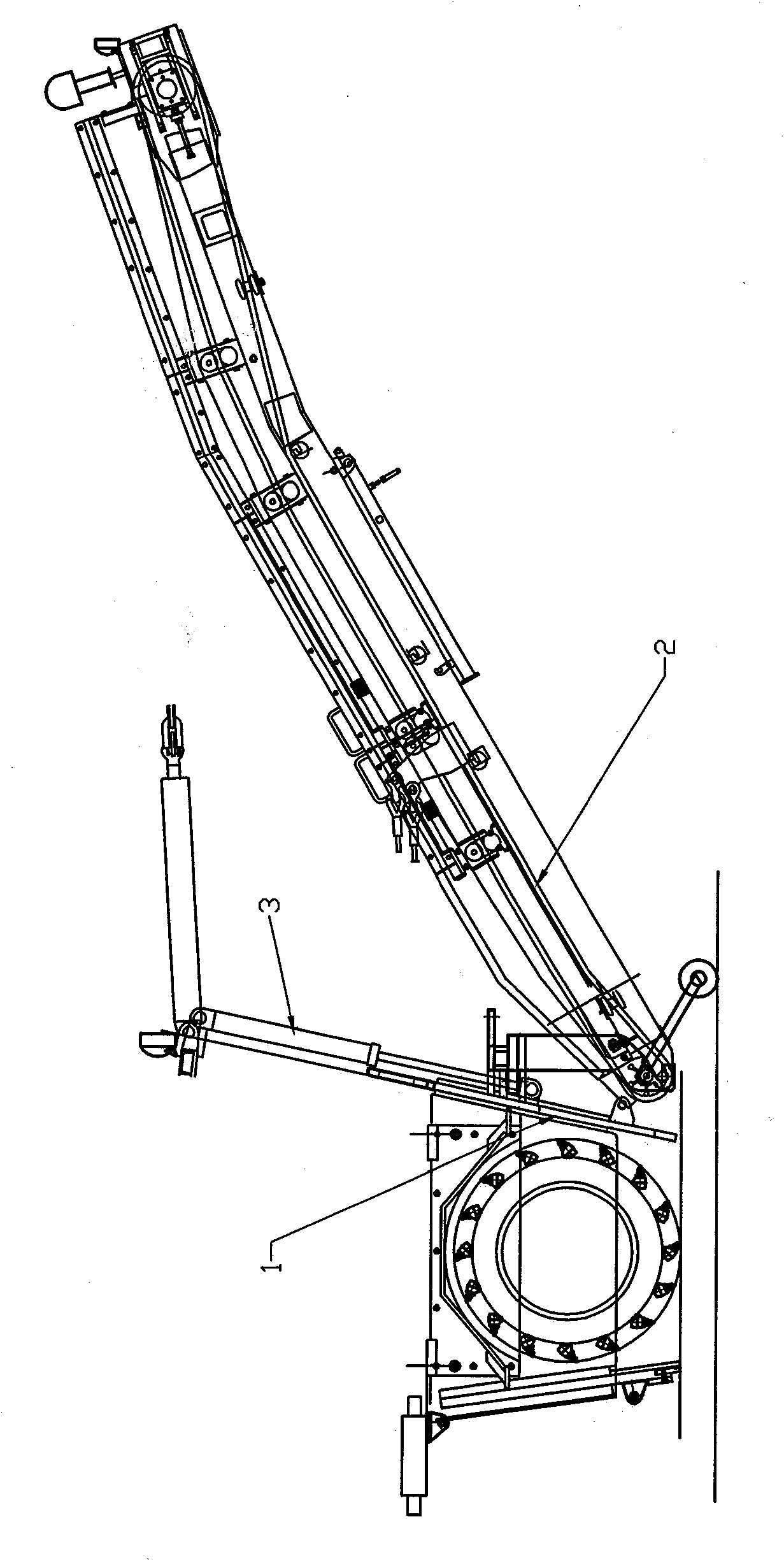

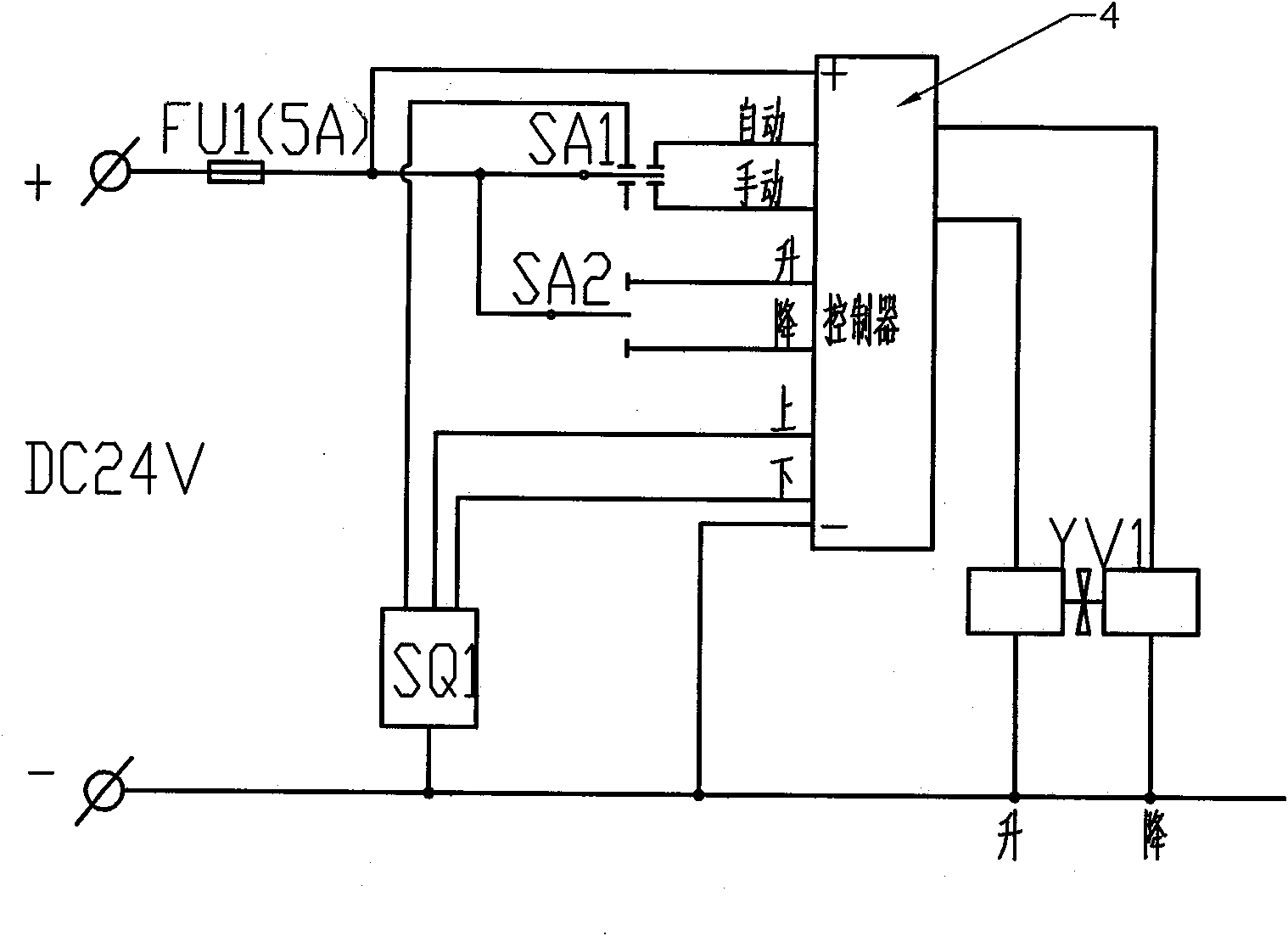

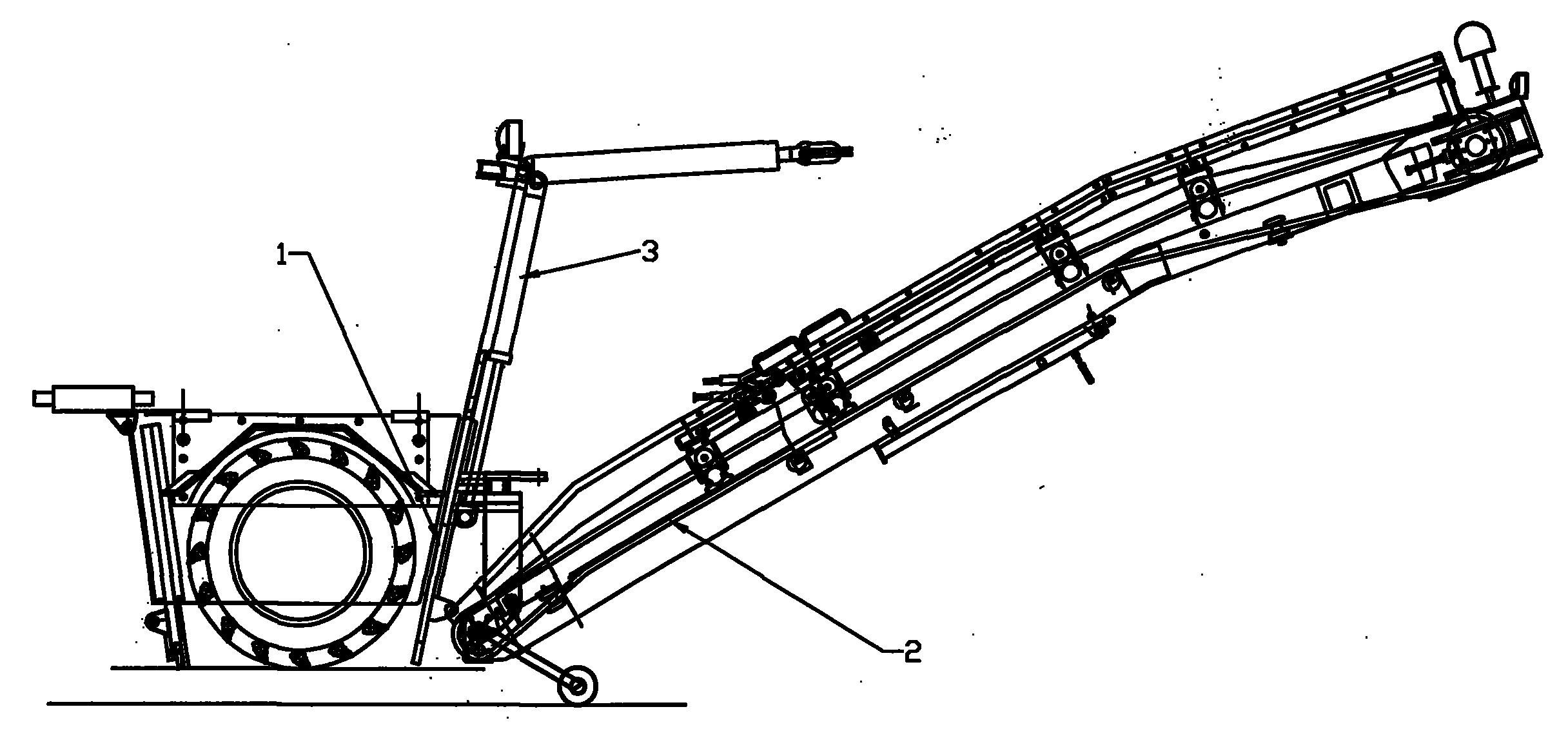

[0008] As shown in the figure, the device includes a conveyor bracket 2 connected with the front discharge door 1 of the milling machine, a hydraulic cylinder 3 that can drive the front discharge door and the conveyor bracket up and down, and a hydraulic cylinder that can control the lifting action of the hydraulic cylinder. The solenoid valve YV1 is installed at the bottom of the conveyor bracket with a position sensor SQ1 for detecting the road surface; the device also includes a controller 4 that can output rising and falling control commands to the solenoid valve YV1; the position sensor SQ1 can be controlled by the controller The signal input part outputs the rising or falling control signal; the control signal input part of the controller is also connected with a manual selection switch SA2 that can input the rising or falling control signal; the controller is also connected to the position sensor SQ1 through a state switch SA1, with To control the position sensor to work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com