On-site construction method of cold recycling asphalt pavement

A technology for asphalt pavement and on-site construction, applied in the field of cold recycled asphalt pavement, can solve the problems of pavement structure damage, semi-rigid base strength, excessive modulus, semi-rigid base fatigue damage, etc., and achieves a high proportion of cold recycling , Improve the level of traffic services and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

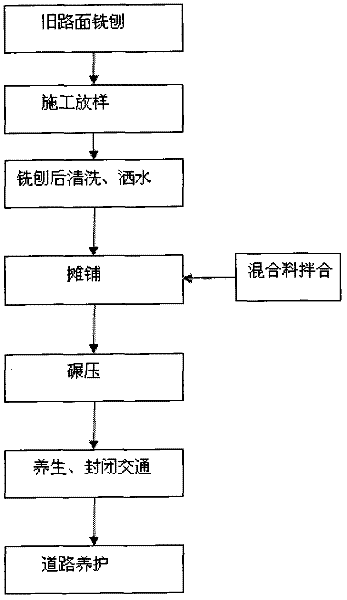

[0024] like figure 1 As shown, the present invention is a field construction method of cold recycled asphalt pavement, and the method comprises the following process steps:

[0025] Step 1: Use pavement milling equipment to dig out the old materials of the asphalt pavement;

[0026] The second step: use the crushing and screening equipment to carry out continuous cycle crushing and screening of the old materials of the asphalt pavement;

[0027] The third step: put the crushed and screened old asphalt pavement material into the finished product hopper, mix the emulsified asphalt with water at 1:1, and mix with the old asphalt pavement mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com