High-modulus asphalt mixture based on old pavement milling material, and preparation method thereof

An asphalt mixture and high modulus technology, which is applied in the field of road engineering, can solve the problems of high production cost of high modulus asphalt mixture, poor regeneration quality of milling materials, and difficulty in popularization, and achieve outstanding economic benefits and low production costs. The effect of reducing and alleviating environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

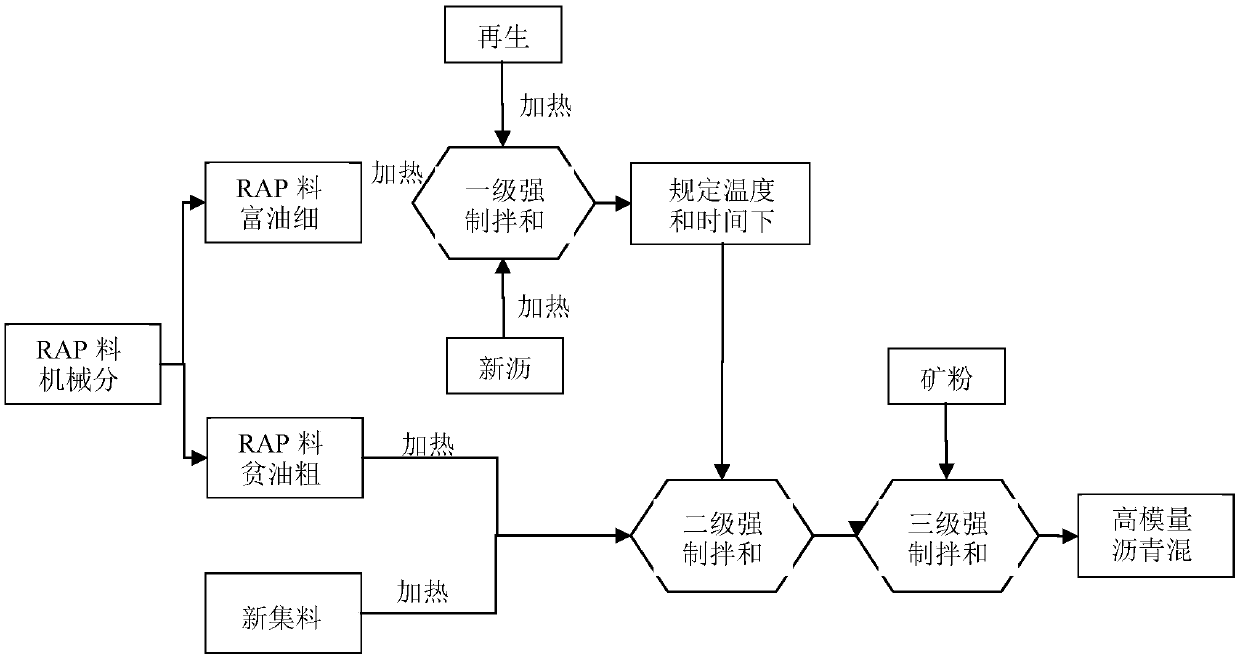

Method used

Image

Examples

Embodiment 1

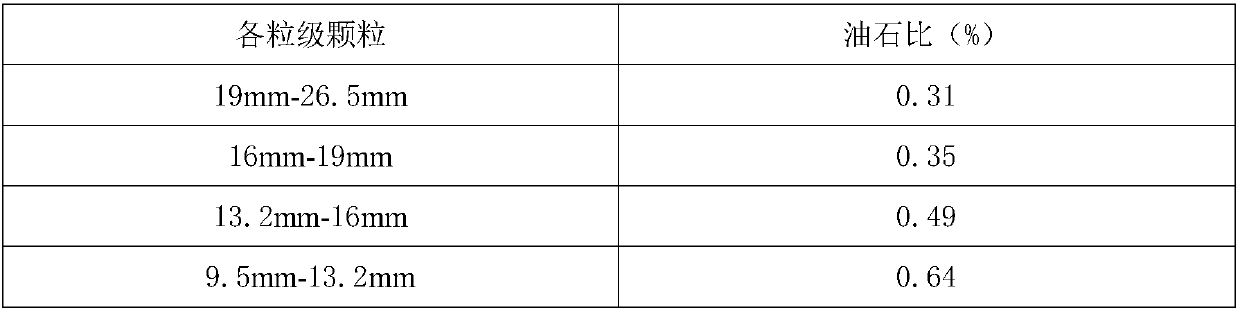

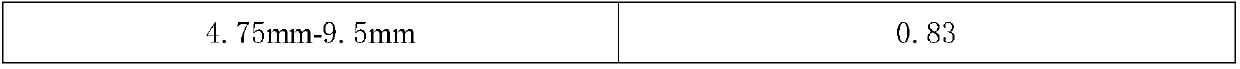

[0044] The embodiment of indoor test: the used old asphalt pavement milling material (RAP material) used in the test is the material of the same particle size specification of the same source, at first the RAP material is carried out mechanical separation in the mixing plant, and is divided into poor oil coarse components (particle size is greater than 4.75 mm) and oil-rich fine components (particle size less than 4.75mm). Then, according to the method T 0735 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011), the asphalt content test is carried out on the lean oil coarse component, and the oilstone of each particle size in the lean oil coarse component is measured by the test. See Table 1 for comparison. Using the method T 0726 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011), the oil-rich fine components were extracted. The results are shown in Table 2, and the extracted old asphal...

Embodiment 2

[0077] Indoor test embodiment, this embodiment is the same as the RAP material poor oil crude component used in the above-mentioned embodiment 1, the RAP material rich oil fine component, new aggregate and slag type, and the difference with embodiment 1 is:

[0078] The regeneration agent is ZSR-100 modified regeneration agent produced by Jiangsu Tiannuo Road Material Technology Co., Ltd., and the dynamic viscosity at 60°C is 101Pa.s.

[0079] The new asphalt adopts TNH-15 hard asphalt produced by Jiangsu Tiannuo Road Material Technology Co., Ltd., and its performance indicators are shown in Table 10.

[0080] Table 10 TNH-15 type hard asphalt technical indicators

[0081] Penetration 25°C (0.1mm)

Softening point ℃

Ductility 25℃(cm)

14

73

16

[0082] See Table 11 for the ratio of raw materials used to prepare a high modulus asphalt mixture in the laboratory test, and see Table 12 for the synthetic gradation of the high modulus asphalt mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com