Self-feedback floating scraping system of pavement milling machine

A milling machine, self-feedback technology, applied in the field of road milling machine self-feedback floating scraper system, can solve the problems of reduced work efficiency, excessive forward resistance of milling work, uneconomical, environmental protection, etc., to improve construction effect and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

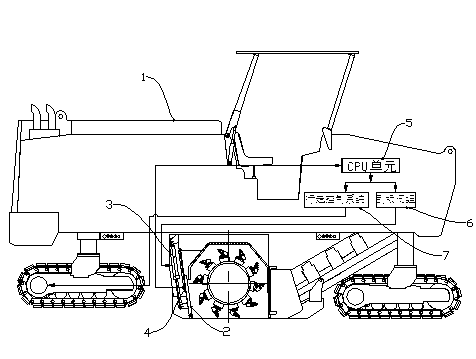

[0008] As shown in the figure, the self-feedback floating scraper system of the road milling machine includes a scraper 2 installed on the lower part of the road milling locomotive 1. The scraper can be driven up and down by the scraper oil cylinder 3 to change the position of the lower end of the scraper. grounding pressure; the system also includes a control system for controlling the lifting of the scraper 2; the control system includes a pressure sensor 4 installed on the scraper and capable of detecting the grounding pressure of the scraper; the detection signal output of the pressure sensor The terminal is connected to a CPU unit 5 capable of processing detection data, and the control instruction output terminal of the CPU unit is connected to the scraper valve group 6 which can control the action of the scraper cylinder, so that the scraper can be controlled in real time according to the detection signal of the pressure sensor. adjust. The CPU unit 5 also includes a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com