Hydraulic system for floating of scraper of pavement milling machine

A floating hydraulic system and milling machine technology, applied in the field of hydraulic systems, can solve the problems of large measurement errors, poor reliability, damage or short circuit of electronic components, etc., to achieve convenient operation, reduce pressing force, and avoid forward resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

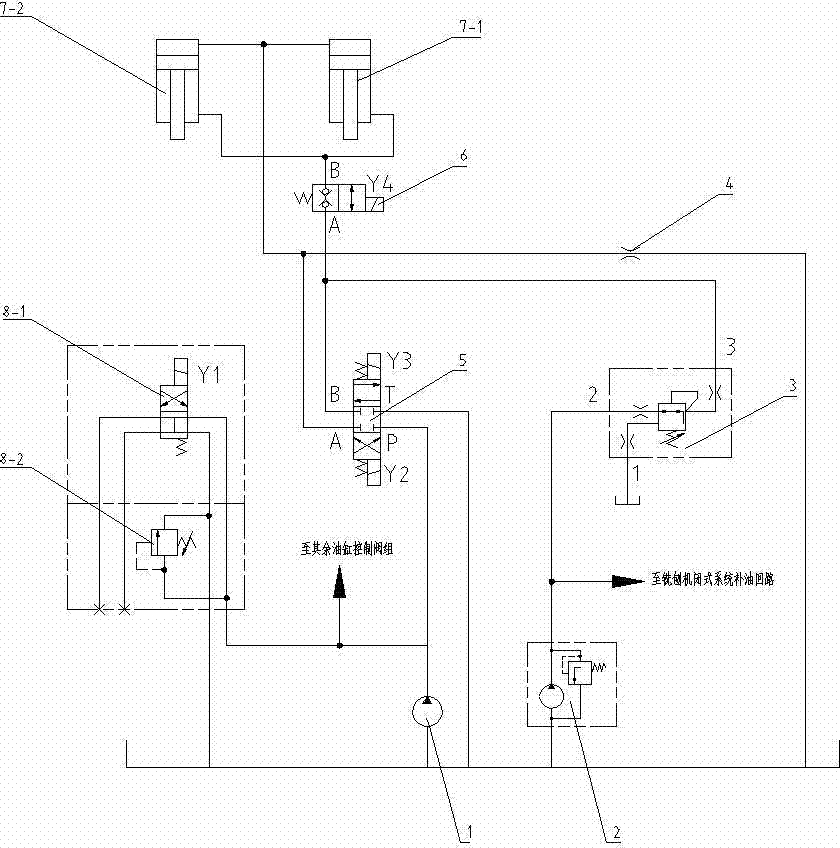

[0022] see figure 1 , the present invention relates to a scraper floating hydraulic system for a road milling machine, the system includes a scraper cylinder with a piston rod vertically downward, and the piston rod of the scraper cylinder is connected to a horizontally arranged scraper ( Specifically, there are two scraper cylinders as shown in the figure, scraper cylinder one 7-1 and scraper cylinder two 7-2), and the upper cavity of the scraper cylinder leads to two oil circuits, one of which is connected to the three-position four The oil port A of the electromagnetic reversing valve 5 is connected, and the other is connected to the oil tank through the throttle valve 4. The lower chamber of the scraper cylinder is divided into two circuits after passing through the two-position two-way solenoid valve 6, and one is connected to the three-position four-way The oil port 2 B of the electromagnetic reversing valve 5 is connected to the oil outlet of the three-way pressure redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com