Hydraulic system for controlling tail gate of pavement milling machine

A hydraulic system and milling technology, applied in the field of hydraulic systems, can solve the problems of engine power consumption, increased tire wear, increased cleaning work, etc., and achieve the effects of reducing energy consumption, reducing ground pressure, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

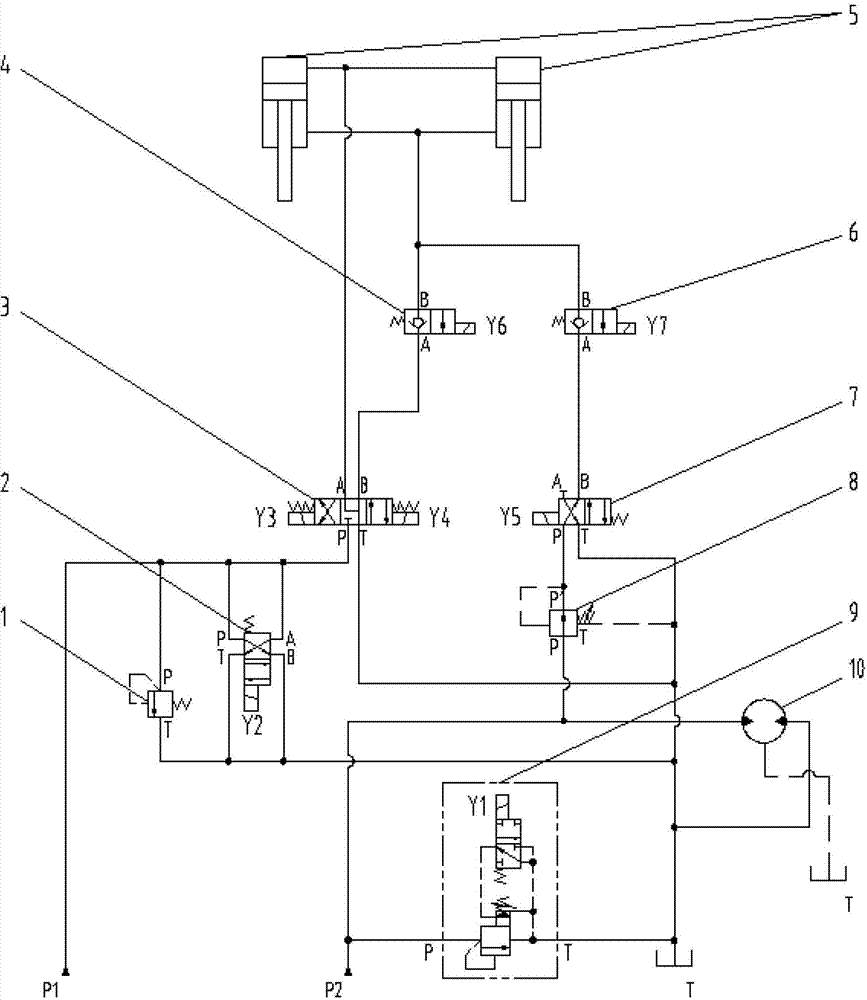

[0023] Such as figure 1 As shown, a hydraulic system for controlling the tailgate of a road milling machine in the present invention includes an overflow valve 1, an electromagnetic overflow valve 9, a two-position four-way electromagnetic reversing valve 2, a two-position four-way electromagnetic reversing valve 7, Normally closed two-position two-way electromagnetic reversing ball valve 4, normally closed two-position two-way electromagnetic reversing ball valve 6, three-position four-way electromagnetic reversing valve 3, conveying motor of belt conveyor, fixed value pressure reducing valve 8 and tailgate Lift cylinder 5,

[0024] The high-pressure oil outlet P1 of the hydraulic system of the road milling machine is divided into four routes, one of which is connected to the oil inlet P of the overflow valve 1, and two routes are connected to the two-position four-way electromagnetic reversing valve 2 respectively. The oil port P is connected with the oil outlet A, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com