In-place heat regeneration integrated machine for bituminous pavements and control method

An asphalt pavement and all-in-one machine technology, which is applied in the field of construction machinery, can solve the problems of excessive manpower and material resources consumption, insufficient heating of recycled materials, heat loss of milling materials, etc., to reduce the consumption of manpower and material resources, heating and mixing time Longer, less heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

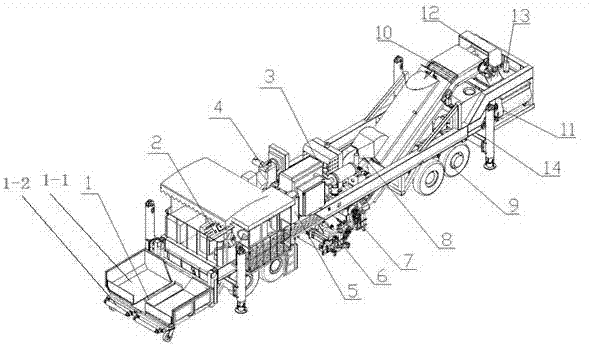

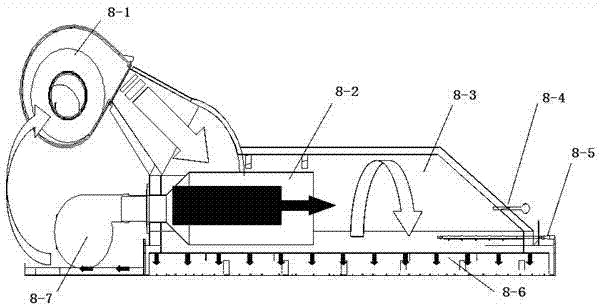

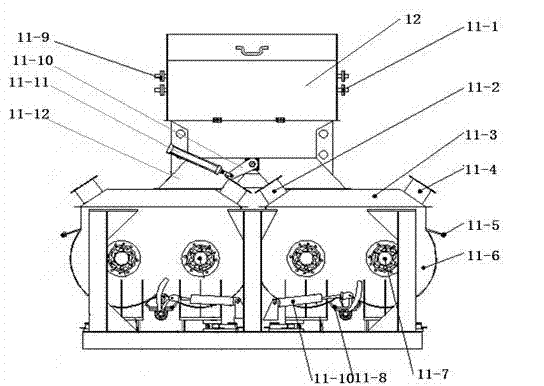

[0045] An in-situ heat regeneration machine for asphalt pavement, comprising a vehicle chassis 9, a new material adding device 1, a milling device, a conveyor 10, a conveyor heating device 8, a stirring pot 11, a stirring pot heating device 13 and a control system 2. The vehicle chassis 9 can walk, and is used to install and carry the parts of the in-situ heat regeneration machine for asphalt pavement, and the power system 3, generator set 4 and hydraulic system 5 are installed on the vehicle chassis 9; the new material adding device 1 is arranged on the vehicle chassis 9 front end, including stuffing box 1-1 and two pressure rollers 1-2 arranged at the front of stuffing box 1-1, used to spread new aggr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com