Quick cutter change milling rotor used on a pavement milling machine

A milling rotor and milling machine technology, applied in the field of milling rotors, can solve the problems of incomplete recycling of waste materials, affecting the quality of newly paved roads, and polluting the environment, so as to ensure the quality of road repairs, avoid waste materials splashing, The smooth effect of the spiral leaf surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

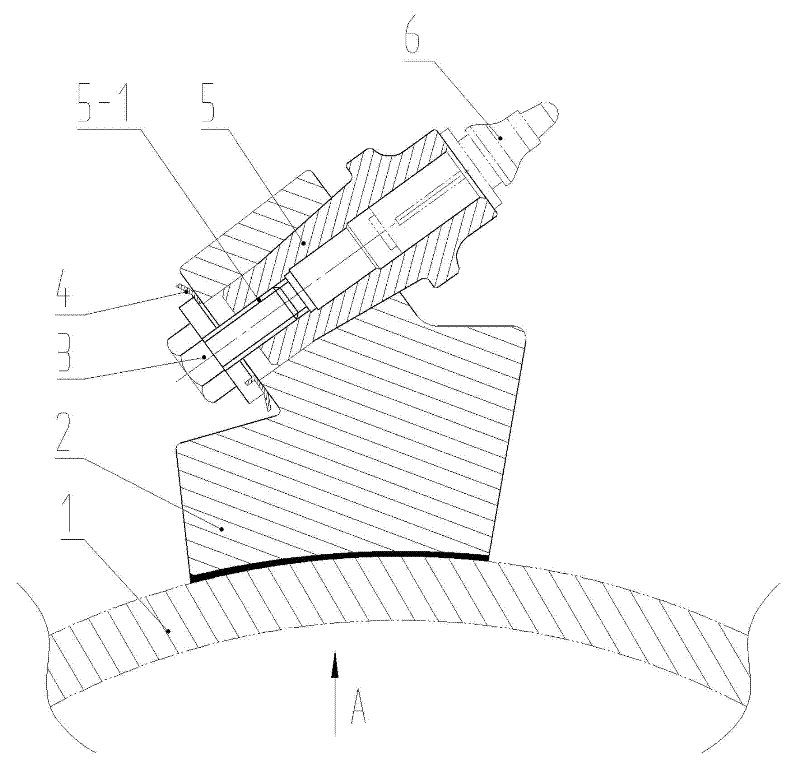

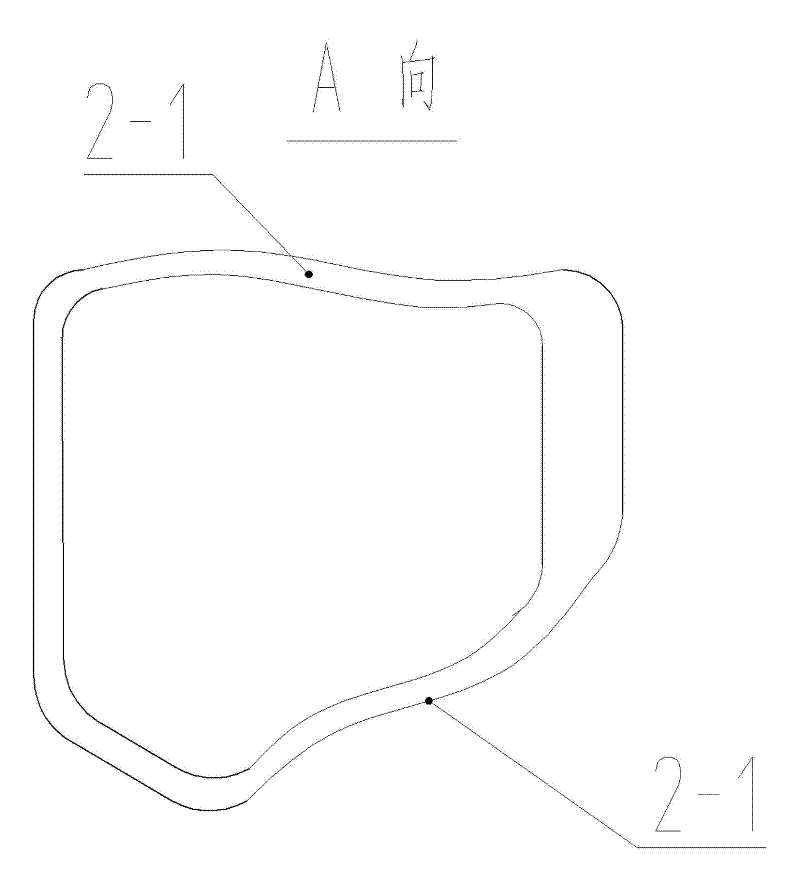

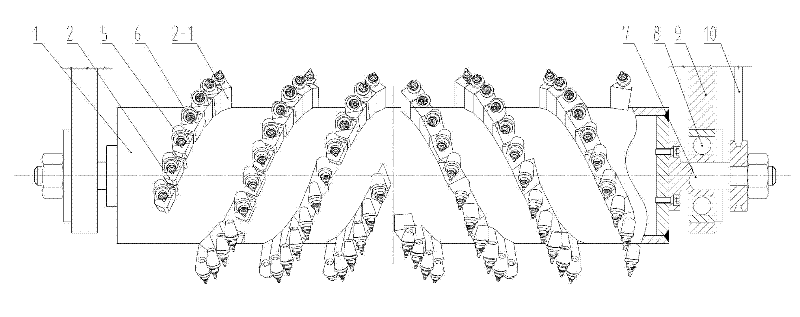

[0015] like figure 1 , figure 2 , image 3 Shown: a milling rotor used on a road milling machine that can quickly change tools, which includes: a cylinder 1, a base 2, a tool holder 5 and a tool head 6. The cylinder shaft 7 at both ends of the cylinder 1 is installed on the milling machine frame 9 through the bearing 8, the cylinder shaft 7 is connected with the power source of the milling machine through the belt 10, and the cylinder shaft 7 is connected with the power source of the milling machine. The power source obtains power to drive the barrel 1 to rotate at a high speed. The cutter head 6 is installed on the cutter holder 5 , and the cutter holder 5 is installed on the base 2 . The bases 2 are multiple, and the multiple bases 2 are divided into two groups, and the two groups of bases 2 are arranged in left-right symmetrical and opposite-handed helical lines, and the bottom surface of the base 2 is welded on the cylindrical surface of the cylinder body 1 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com