Pavement milling apparatus

A milling machine and milling cutter technology, which is applied in the field of road milling machines, can solve the problems of single function of milling unit, incompetence, time-consuming and laborious replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

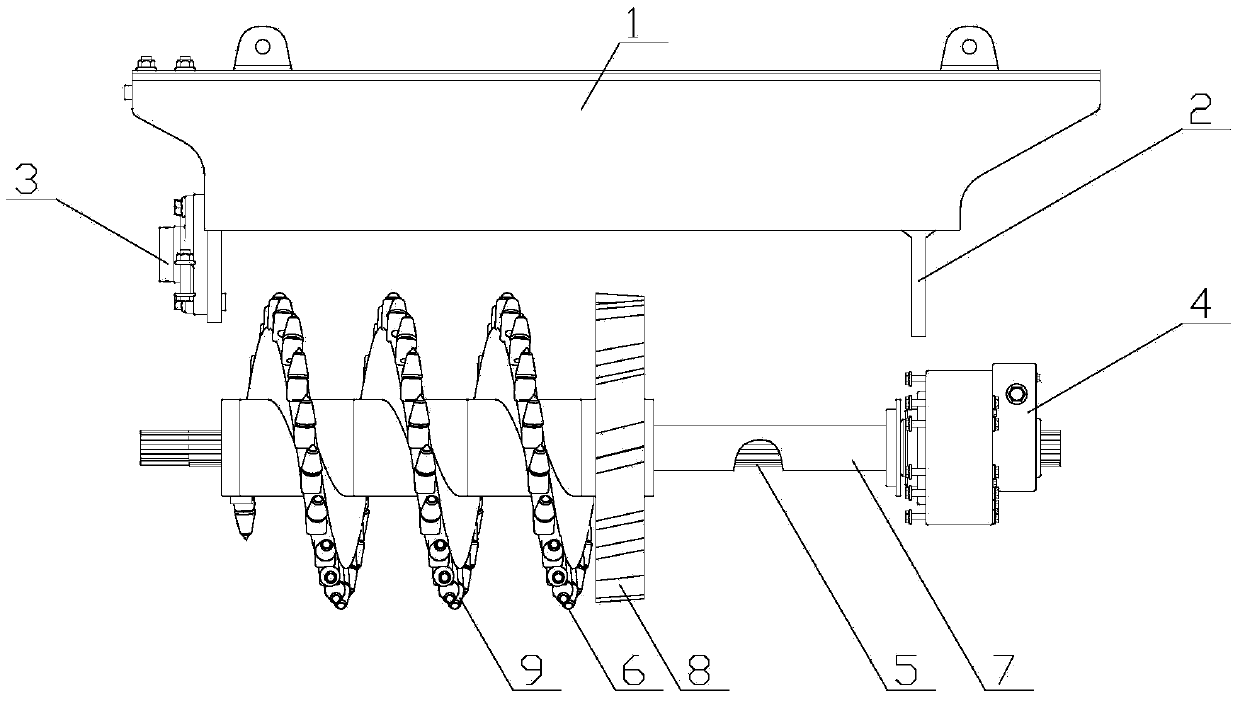

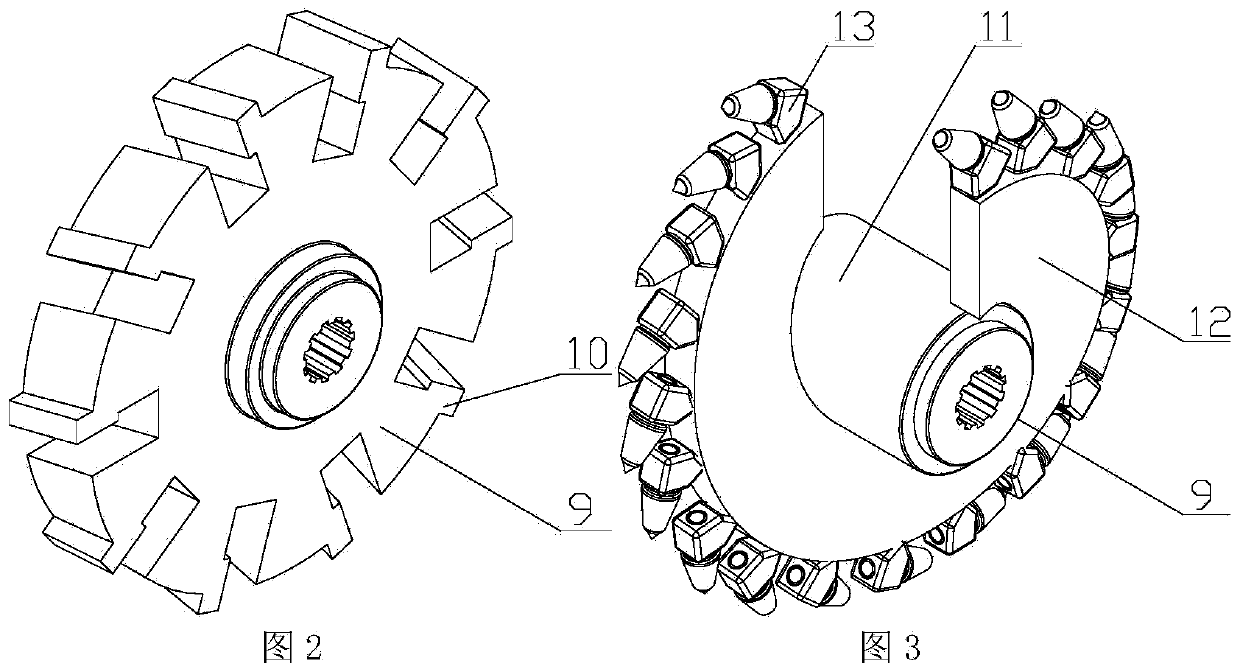

[0025] Embodiment 1: as figure 1 As shown, the road surface milling device includes a main bracket 1, a motor fixing plate 2 is provided on one side of the bottom of the main bracket 1, and a tool adjustment clamping plate 3 is movable on the other side of the bottom of the main bracket 1, and a motor fixing plate 2 is provided on the other side of the bottom of the main bracket 1. A drive motor 4 is provided on the top, and the drive motor 4 is an electric motor; a spline shaft 5 is coaxially fixed on the output shaft of the drive motor 4, and the top of the spline shaft 5 passes through the tool adjustment clamp 3, and the spline shaft 5 The upper sleeve is equipped with a milling cutter wheel 6 and a limit sleeve 7. The limit sleeve 7 enables the milling cutter wheel 6 to be positioned accurately on the spline shaft 5 and does not move when working; the drive motor 4 passes through the spline shaft 5 Drive the milling cutter wheel 6 to rotate; the milling cutter wheel 6 inc...

Embodiment 2

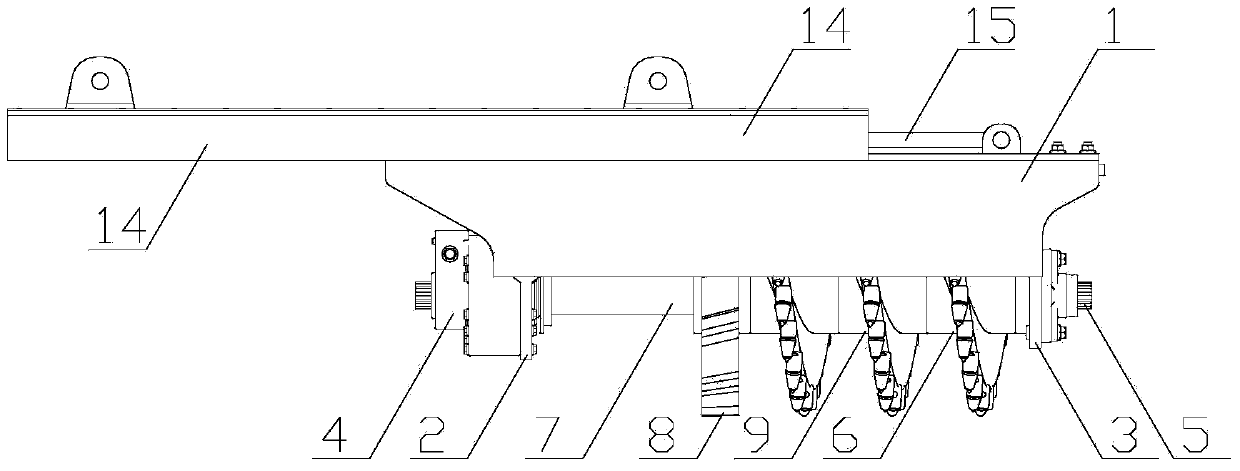

[0026] Embodiment 2: as Figure 4 to Figure 6 As shown, the road milling device includes a main support 1 and a telescopic adjustment plate 14; a motor fixing plate 2 is provided on one side of the bottom of the main support 1, and a cutter adjustment clamping plate 3 is movable on the other side of the bottom of the main support 1 , a drive motor 4 is arranged on the motor fixing plate 2, and the drive motor 4 is an electric motor; a spline shaft 5 is coaxially fixed on the output shaft of the drive motor 4, and the top end of the spline shaft 5 passes through the cutter adjustment clamping plate 3 , a milling cutter wheel 6 and a limit sleeve 7 are set on the spline shaft 5, and the limit sleeve 7 enables the milling cutter wheel 6 to be positioned accurately on the spline shaft 5, and will not move when working; the drive motor 4. Drive the milling cutter wheel 6 to rotate through the spline shaft 5; the milling cutter wheel 6 includes a side cutter milling cutter wheel 8 a...

Embodiment 3

[0027] Embodiment 3: as Figure 8 to Figure 11 As shown, the road milling device includes a main support 1 and two telescopic adjustment plates 14; a motor fixing plate 2 is provided on one side of the bottom of the main support 1, and a tool adjustment clamping plate is movable on the other side of the bottom of the main support 1 3. A drive motor 4 is provided on the motor fixing plate 2, and the drive motor 4 is a hydraulic motor; a spline shaft 5 is coaxially fixed on the output shaft of the drive motor 4, and the top of the spline shaft 5 passes through the tool adjustment clamping plate 3. A milling cutter wheel 6 and a limit sleeve 7 are set on the spline shaft 5. The limit sleeve 7 enables the milling cutter wheel 6 to be positioned accurately on the spline shaft 5 and does not move when it is working; The motor 4 drives the milling cutter wheel 6 to rotate through the spline shaft 5; the milling cutter wheel 6 includes a side cutter milling cutter wheel 8 and three ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com