Planing mill for recycling pavement

A technology of milling machine and pavement, applied in the fields of asphalt pavement maintenance machinery and pavement milling machine, can solve the problems of increasing the labor intensity of operators, increasing the workload, and reducing the life of the tool, so as to reduce the power loss of throwing materials and reduce the The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

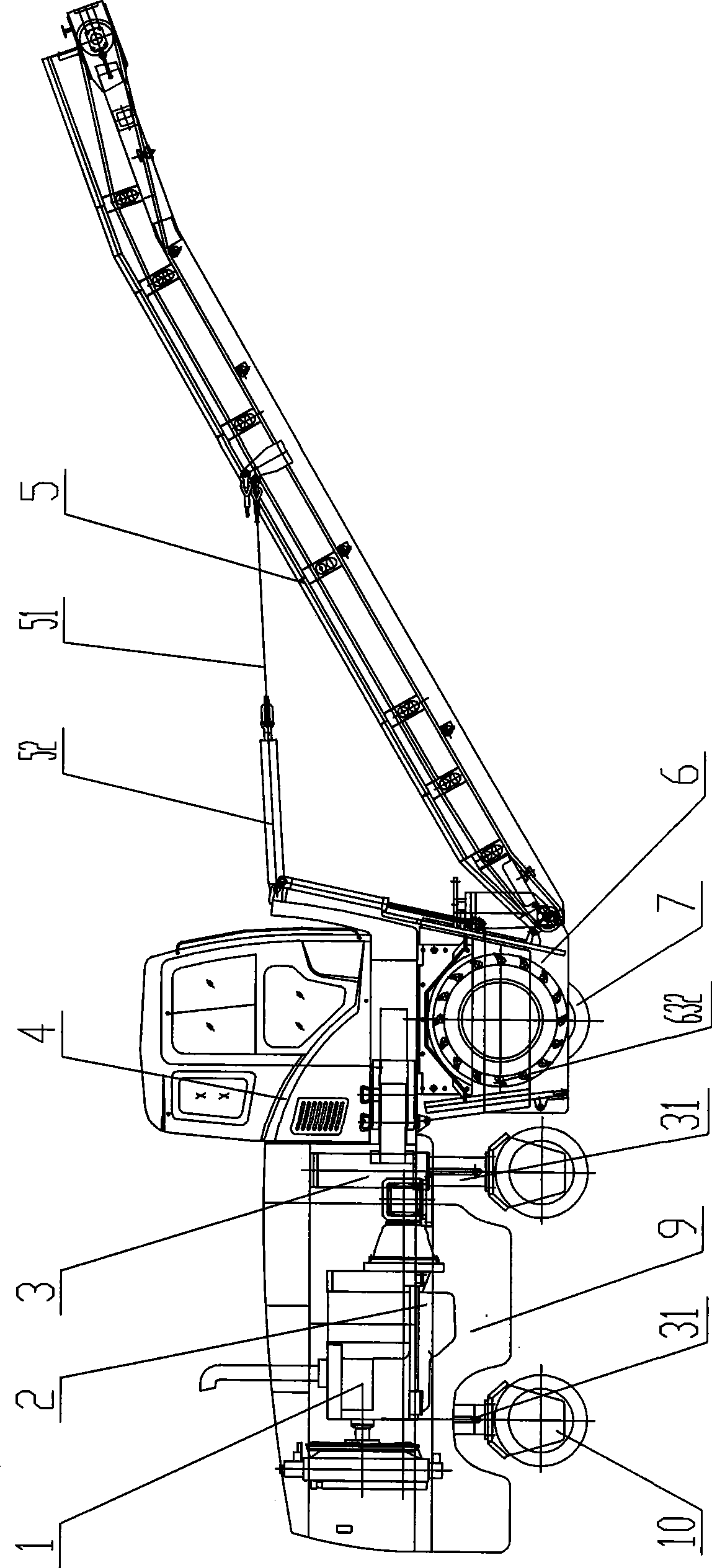

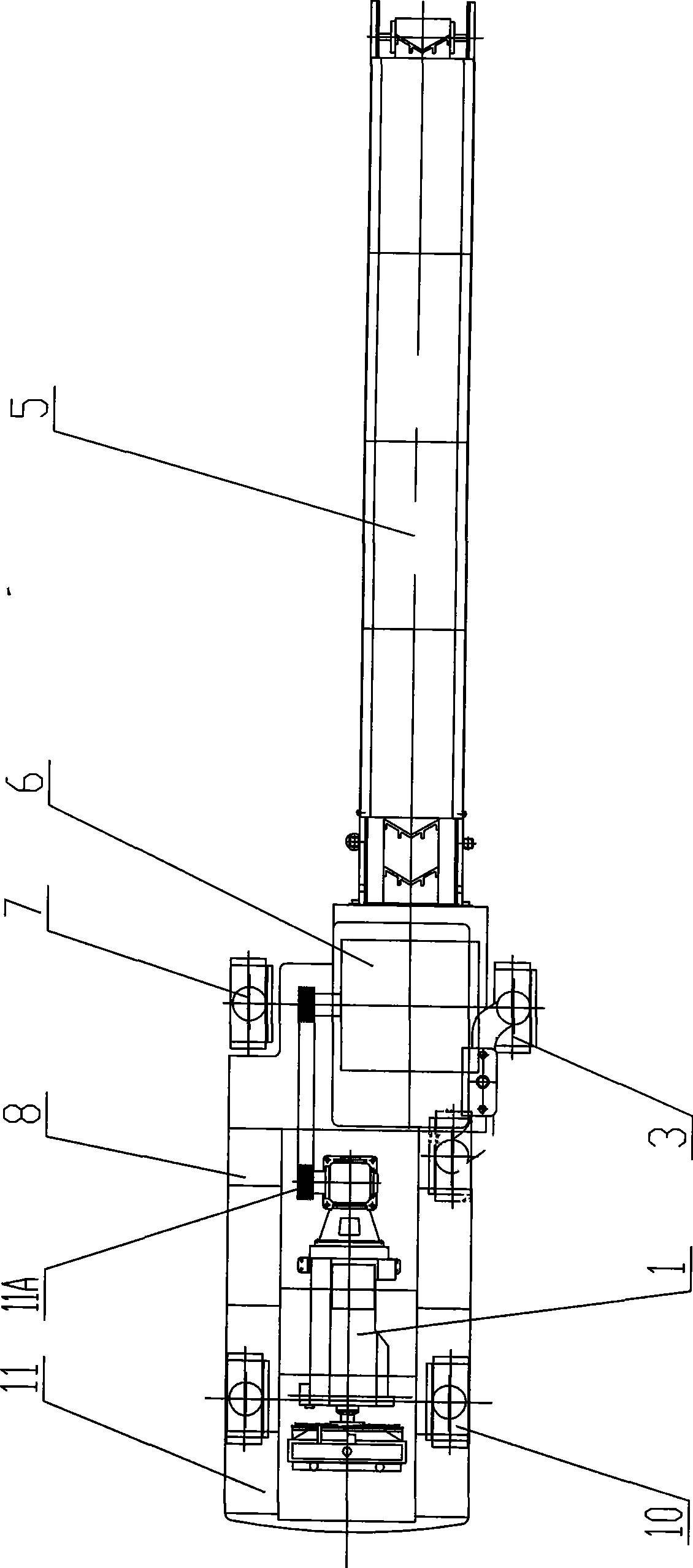

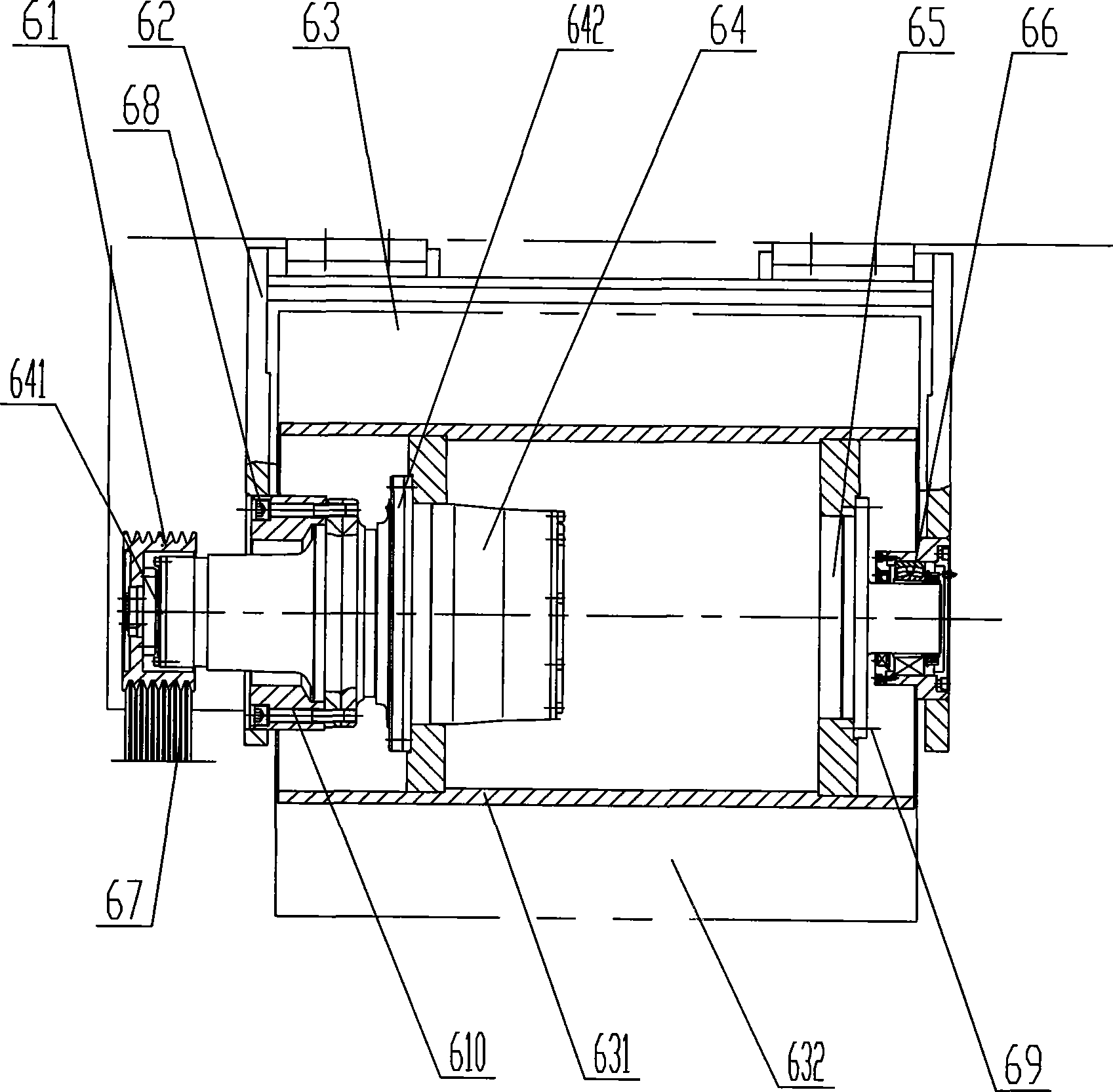

[0018] Such as figure 1 , figure 2 As shown, the present invention comprises engine 1, frame 2, front swing wheel 3, driver's cab 4, single-stage belt conveyor 5, working device 6, front wheel 7, hydraulic oil tank 8, water tank 9, rear steering wheel 10, diesel oil Box 11. The engine 1 is fixed on the frame 2, and the front and rear ends of the frame 2 are respectively supported on two rear steering wheels 10, the front swing wheel 3 and the front wheel 7 by the lifting support column 31. The hydraulic oil tank 8 and the diesel tank 11 are arranged on one side of the fuselage, and the water tank 9 is arranged on the lower side of the fuselage for supplying water to the sprinkler system. The working device 6 is arranged between the front wheel 7 and the front swing wheel 3, and the single-stage belt conveyor 5 is arranged on the front side of the working device 6, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com