Pavement milling machine

A milling machine and frame technology, applied in the field of road equipment, can solve problems such as oil cylinder leakage, reduced safety and reliability of road milling machines, and pipe bursts in hydraulic systems, so as to enhance safety and reliability and reduce hydraulic pressure. Effect of internal oil leakage and risk of cylinder subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

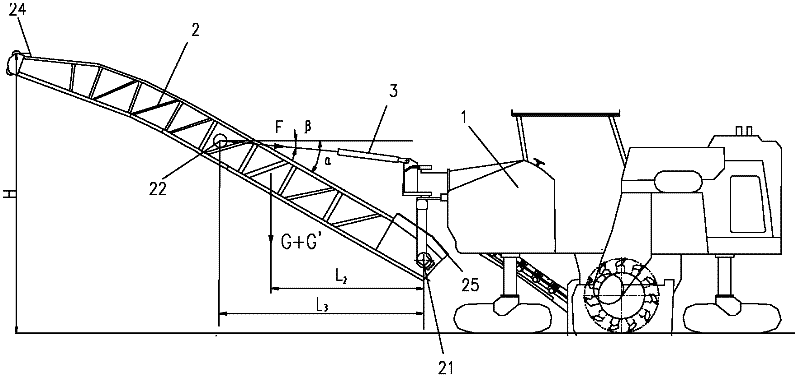

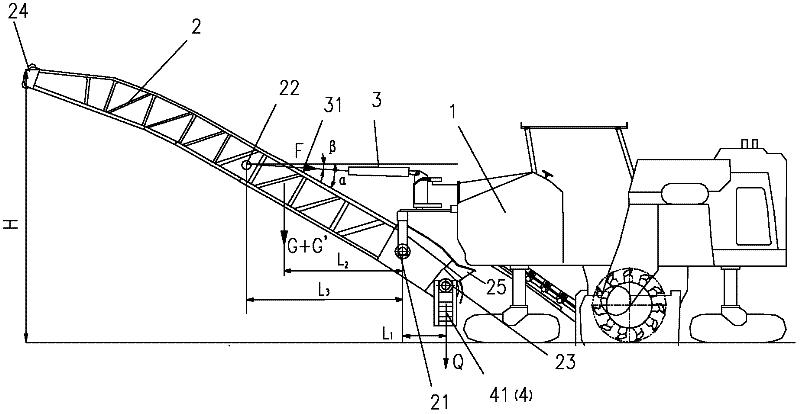

[0032] In the present invention, in the case of no contrary description, the used orientation words such as "up and down" are usually defined under the normal use of the road milling machine provided by the present invention, that is figure 1 and figure 2 direction shown.

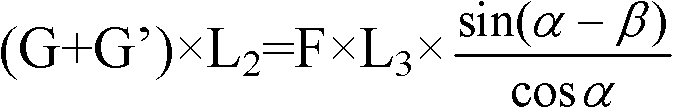

[0033] Such as figure 2 As shown, the present invention provides a road milling machine, which includes a frame 1, a conveyor belt conveyor 2 and a lifting cylinder 3, and the conveyor belt conveyor 2 has an input end 25 and an output end 24 arranged oppositely, The conveyor belt conveyor 2 is hinged on the frame 1 through the first hinge point 21, one end of the lifting cylinder 3 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com