Novel powder manufacturing apparatus and process

A new type of re-crushing technology, which is applied in the field of crushing and grinding, can solve the problems of materials being easily impacted, excessive particle size controllability of unqualified fine powder, and low powder making efficiency, so as to achieve slow running speed and improve the production efficiency. Powder effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

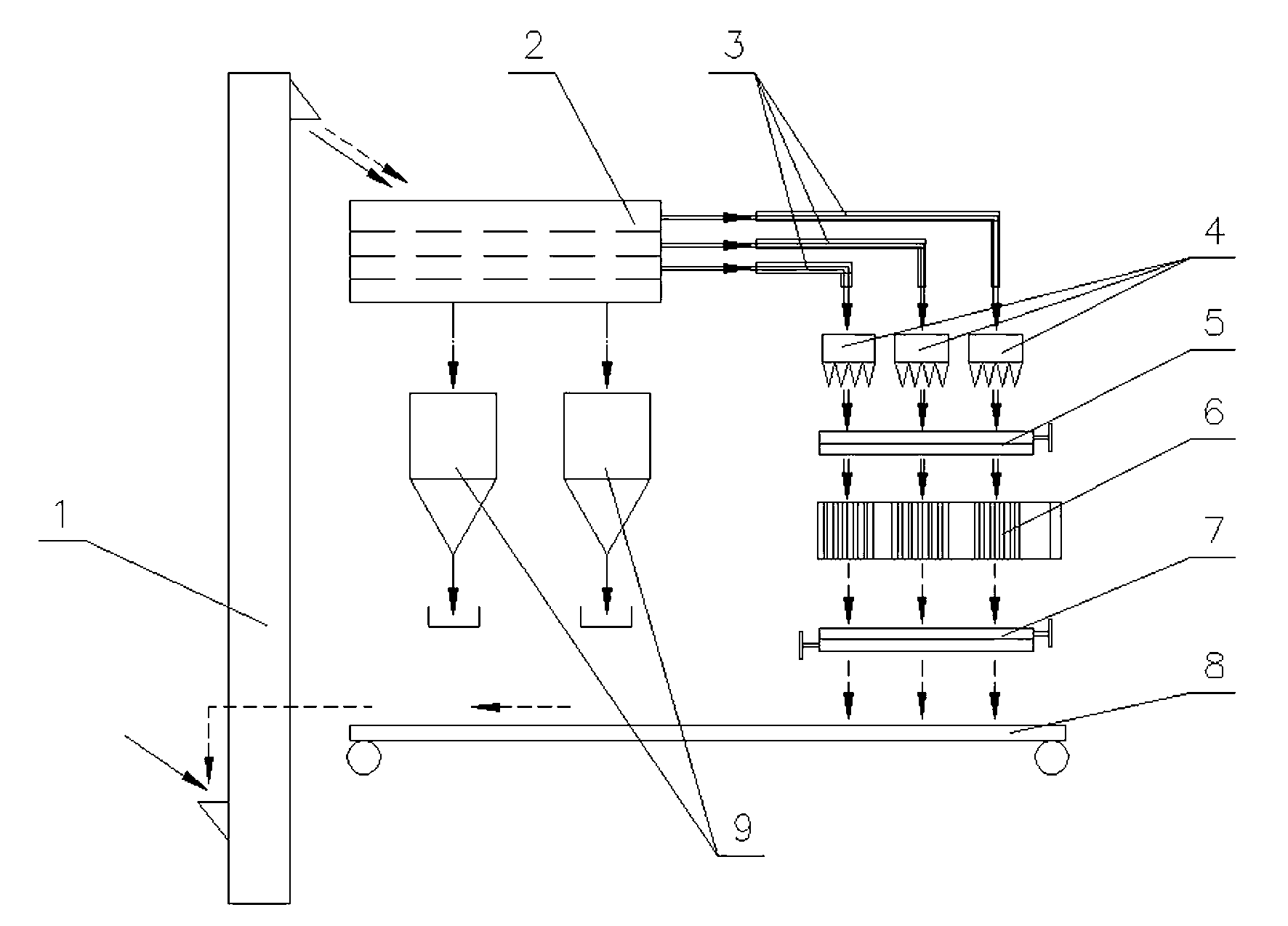

[0020] A new type of milling equipment, including a conveyor 1, a screening machine 2, a material distribution device 3, a material distribution bin 4, a feeding device 5, a crusher 6, a discharge device 7, a conveyor 8, and a powder bin 9. The outlet of the conveyor 1 is connected to the inlet of the screening machine 2, the upper outlet of the screening machine 2 is connected to the material distribution device 3, the material distribution bin 4 is connected to the screening machine 2 through the material distribution pipe, and the feeding device 5 is installed at the outlet of the material distribution bin 4 , the feeding device 5 is connected to the inlet of the crusher 6, the outlet of the crusher 6 is provided with a discharge device 7, the discharge device 7 is connected to the conveyor 8, the outlet of the conveyor 8 is connected to the inlet of the conveyor 1, and the lower outlet of the screening machine 2 It is connected with the powder bin 9 that does not need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com