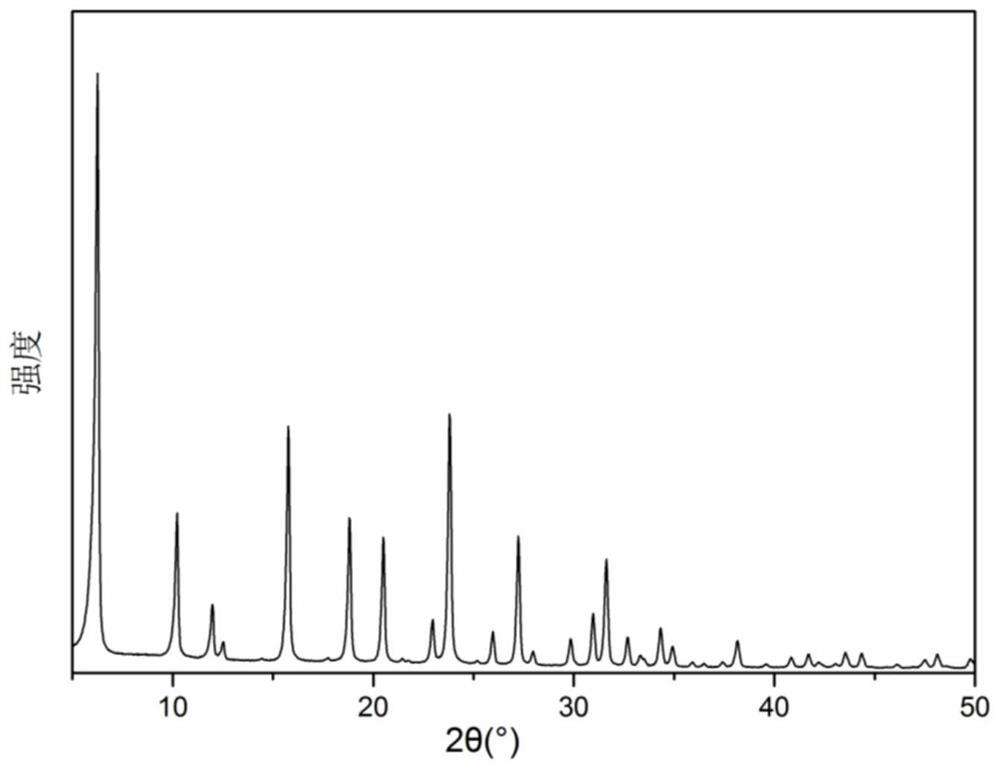

Fluorine-containing high-silicon Y molecular sieve and preparation method thereof

A molecular sieve and high silicon technology, applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of expensive crown ethers, high toxicity, and limited industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

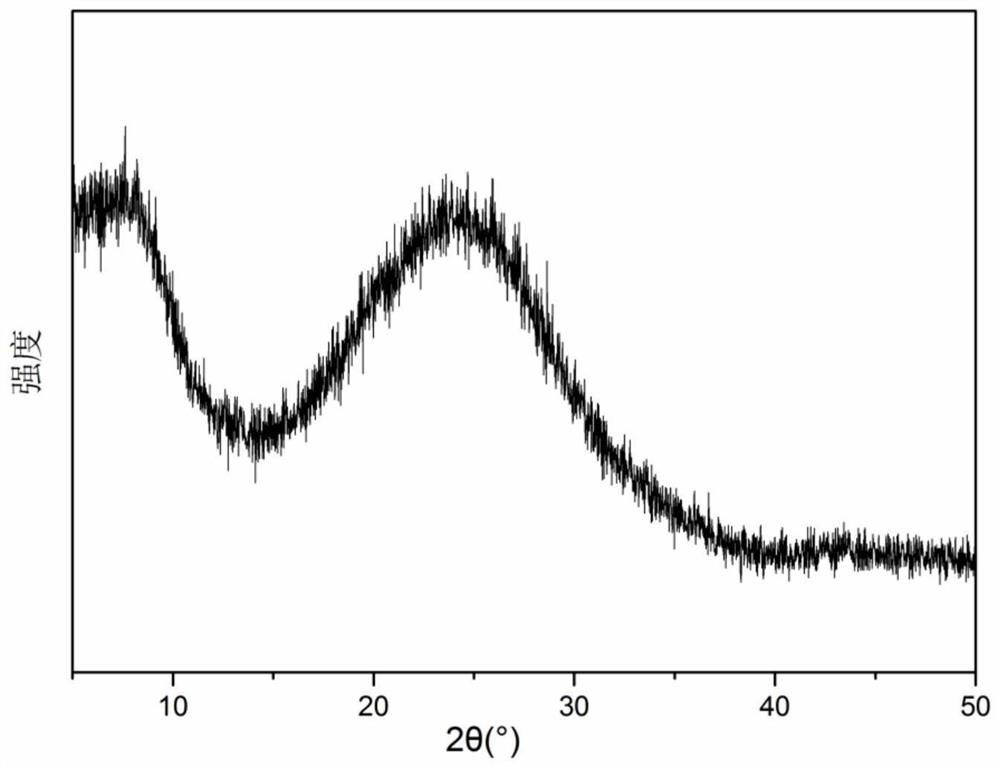

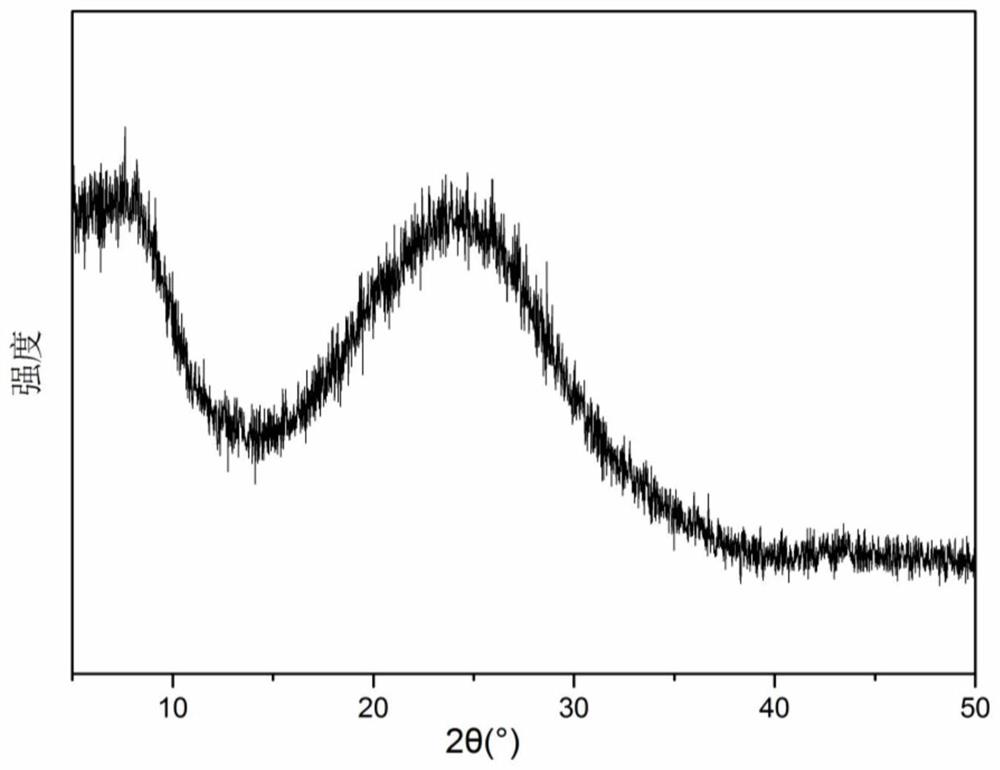

Embodiment 1

[0128] The preparation of embodiment 1 sample S1

[0129]Preparation of guiding agent A: 0.23g sodium hydroxide (analytically pure, Tianjin Kemiou Chemical Reagent Co., Ltd.), 0.35g sodium aluminate (chemically pure, China Pharmaceutical (Group) Shanghai Chemical Reagent Company) were dissolved in 19.06g IV Methylammonium hydroxide (25% aqueous solution, Aladdin Reagent (Shanghai) Co., Ltd.) was stirred until clarification, and then 14.00 g of ethyl orthosilicate (chemically pure, China Pharmaceutical (Group) Shanghai Chemical Reagent Company) was added dropwise and cooled at room temperature. Stir for 2h. The above solution was left to stand at 25°C for 12h and then transferred to 80°C for 48h of rotational aging.

[0130] Prepare synthetic gel C: join 0.13g sodium aluminate, 0.07g sodium hydroxide in 10.84g tetrapropyl ammonium hydroxide (25wt%) solution and stir until clear, and dropwise add 13.33g silica sol (SiO 2 : 30wt%, Shenyang Chemical Co., Ltd.) stirred for 0.5h, ...

Embodiment 2

[0134] The preparation of embodiment 2 sample S2

[0135] Preparation of directing agent A: Dissolve 1.03g of alumina (China Pharmaceutical (Group) Shanghai Chemical Reagent Company, 65wt%) in 19.24g of tetraethylammonium hydroxide (25% aqueous solution, Aladdin Reagent (Shanghai) Co., Ltd.) and stir Until clarification, 14.00 g of ethyl orthosilicate (chemically pure, China Pharmaceutical (Group) Shanghai Chemical Reagent Company) was added dropwise and stirred at room temperature for 2 h. The above solution was rotatably aged at 75°C for 36h.

[0136] Preparation of synthetic gel C: 0.08g of sodium aluminate (Al 2 o 3 : 51wt%, Na 2 (2:41wt%, Tianjin Guangfu Chemical Co., Ltd.) was added to 4.71g tetraethylammonium hydroxide (25wt%) solution and stirred until clarification, and 13.33g silica sol (SiO 2 : 30wt%, Shenyang Chemical Co., Ltd.) stirred for 0.5h, then added 0.80g hydrofluoric acid (40wt%), then added 2.46g of the above-mentioned directing agent and stirred for ...

Embodiment 3

[0140] The preparation of embodiment 3 sample S3-S30

[0141] See Table 1 for the raw material types, molar ratio, crystallization conditions, water-to-silicon ratio, and product crystal structure and composition of samples S3-S30. See Table 2 for the aging temperature, time, aging method and amount of the directing agent. The batching process Same as the preparation of sample S1 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com