Preparation method for composite denitration catalyst with layered structure

A denitration catalyst, layered structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of limited scale application, low catalyst effect, narrow temperature window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) With 150g of 1.0wt% oxalic acid solution, add 1.6g of ammonium molybdate and stir to dissolve, then add 25.4g of cerium nitrate to its dissolution, and pre-prepared 30wt% organic (hexadecyltrimethylammonium bromide) Add 50 g of modified montmorillonite (organic matter content: 30 wt%) slurry to the above solution, place it at 20° C. and stir for 3 days to obtain a suspension, wherein the molar ratio of molybdenum to cerium is 0.15:1;

[0024] (2) Stir the above suspension at 80°C for 6h to obtain a mixture, then add 0.10g (accounting for 0.2wt% of the mixture) of polyethylene oxide, stir the mud, extrude, and dry at 120°C for 8h to obtain a catalyst Precursor;

[0025] (3) The above catalyst precursor was placed in a muffle furnace and calcined at 550° C. for 5 h to obtain a sample, wherein the total content of cerium and molybdenum metal elements was 44%. The transmission electron microscope image of the prepared catalyst is shown in figure 1 As shown, it can be ...

Embodiment 2

[0028] (1) With 120g of citric acid solution of 1.5wt%, stir and add 1.0g ammonium molybdate to its dissolution, then add 14.4g of cerium chloride to its dissolution, pre-prepared 18wt% organic (tetradecyltrimethyl Ammonium bromide) modified attapulgite (organic matter content 25wt%) slurry 80g was added to the above solution, placed at 30°C and stirred for 2 days to obtain a suspension, wherein the molar ratio of molybdenum to cerium was 0.1:1;

[0029] (2) Stir the above suspension at 100°C for 4h to obtain a mixture, then add 0.2g of polyethylene oxide (accounting for 0.35wt% of the mixture), stir the mud, extrude, and dry at 110°C for 16h to obtain a catalyst Precursor;

[0030] (3) The above catalyst precursor was put into a muffle furnace and calcined at 600° C. for 4 hours to obtain a sample, wherein the total content of cerium and molybdenum metal elements was 39%.

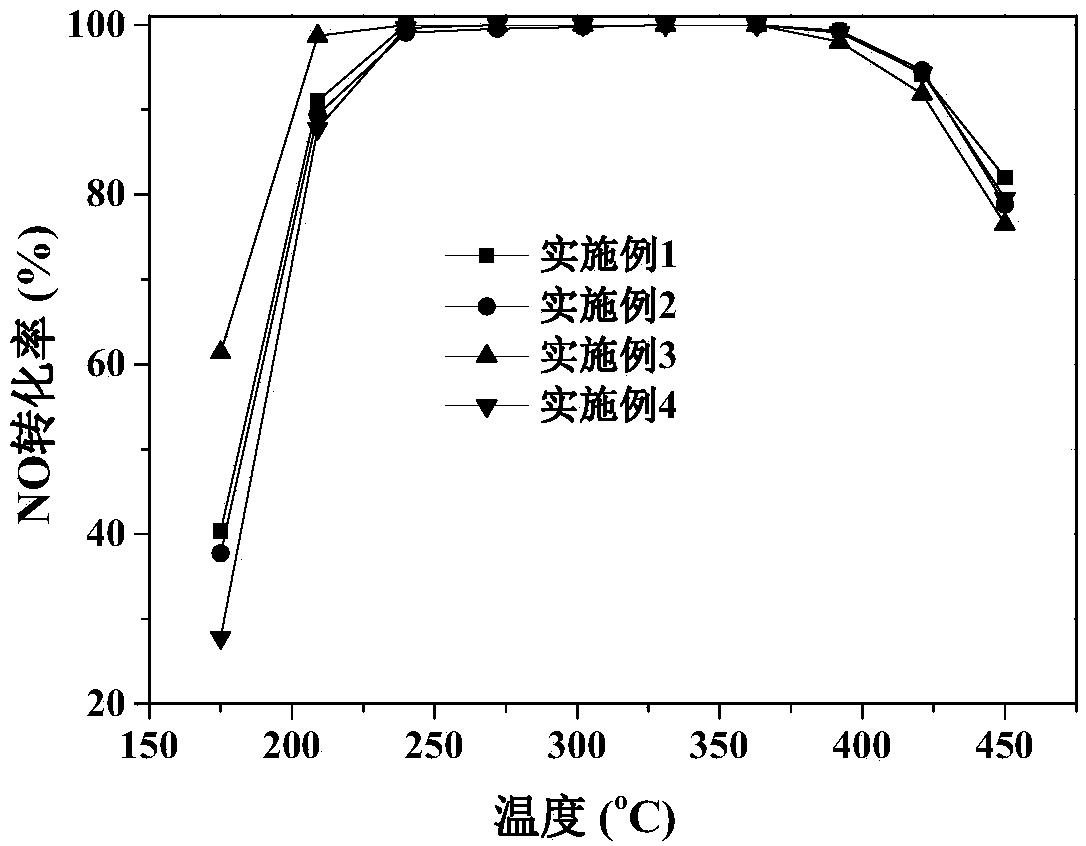

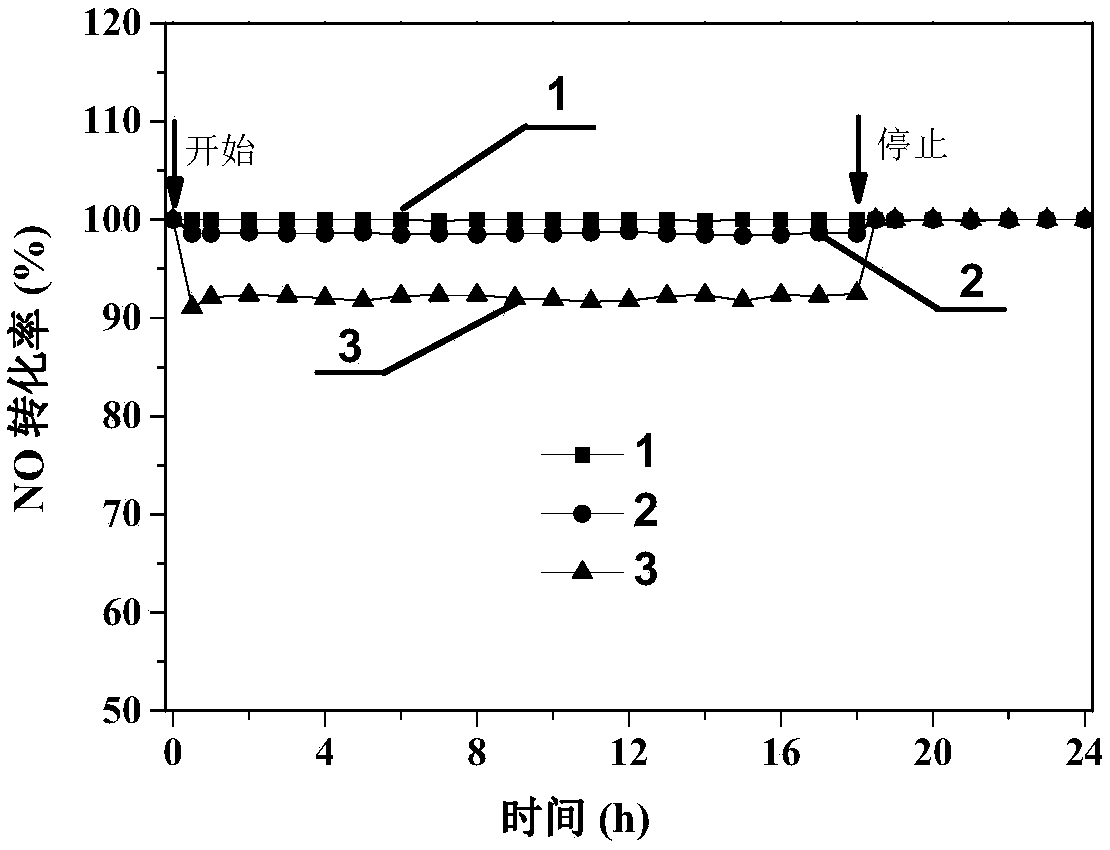

[0031] (4) Denitrification rate test: the composition of the simulated gas is: NO (850ppm), NH 3 (850...

Embodiment 3

[0033](1) With 150g of 2.0wt% oxalic acid solution, stir and add 1.4g ammonium paramolybdate until it dissolves, then add 25.4g cerium nitrate until it dissolves, the pre-prepared 20wt% organic (octadecyl trimethyl bromide Ammonium chloride) modified montmorillonite (organic matter content 35wt%) slurry 75g was added to the above solution, placed at 40°C and stirred for 1 day to obtain a suspension, wherein the molar ratio of molybdenum to cerium was 0.15:1;

[0034] (2) Stir the above suspension at 90°C for 5h to obtain a mixture, then add 0.3g of polyethylene oxide (accounting for 0.55wt% of the mixture), stir the mud, extrude, and dry at 100°C for 24h to obtain a catalyst Precursor;

[0035] (3) The above catalyst precursor was placed in a muffle furnace and calcined at 500° C. for 6 hours to obtain a sample, in which the total content of cerium and molybdenum metal elements was 42%.

[0036] (4) Denitrification rate test: the composition of the simulated gas is: NO (850pp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com