Method for preparing semicoke from low-rank coal

A low-rank coal and semi-coke technology, applied in the field of semi-coke preparation, can solve the problems of low fixed carbon content and calorific value, can not meet blast furnace injection, poor grindability of semi-coke, etc., and achieves fixed carbon and calorific value. High, simple operation method of equipment and device, good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

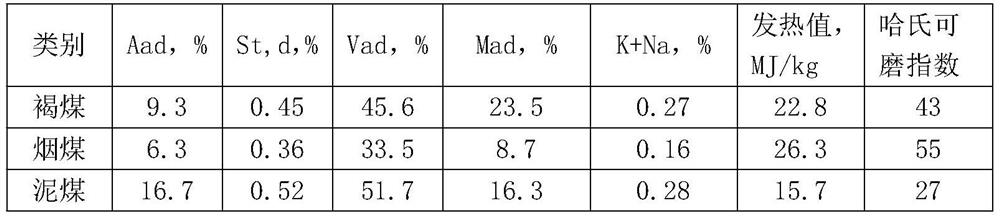

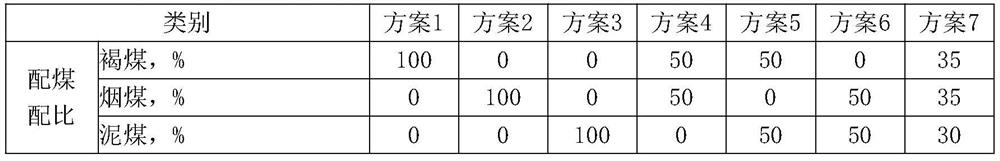

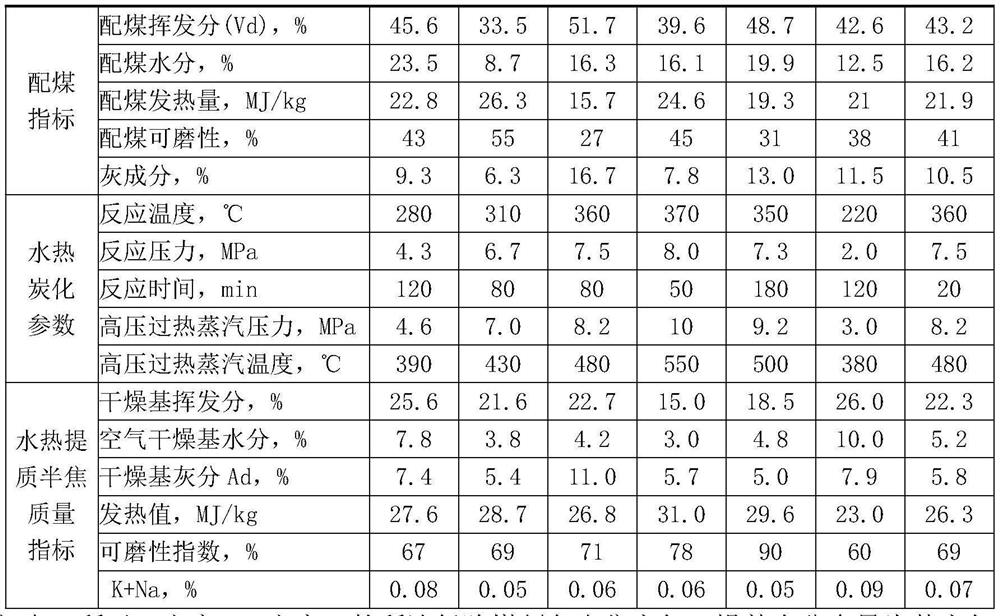

[0039] The present invention will be further described below in conjunction with the examples, as shown in Table 1-Table 2.

[0040]A method for preparing semi-coke from low-rank coal, comprising the following steps:

[0041] 1) Low-rank coal pre-crushing, the low-rank coal is pre-crushed, so that the coal with a particle size of less than 3mm accounts for 75-80% of its total mass;

[0042] 2) Carry out hydrothermal carbonization treatment on low-rank coal, first load crushed low-rank coal into the high-pressure reactor, seal the high-pressure reactor after coal loading is completed; control the reaction temperature and pressure in the high-pressure reactor; Introduce high-pressure superheated steam to heat the coal-water mixture in the high-pressure reactor for 20 to 180 minutes, and the low-rank coal undergoes a hydrothermal carbonization reaction to obtain a hydrothermal carbonization liquid;

[0043] 3) Separating the hydrothermal carbonization liquid, performing solid-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com