Method for preparing bio-oil by catalytically degrading lignin

A biomass oil and catalytic degradation technology, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of unstable biomass oil yield, low biomass oil yield, and high reaction conditions. Inexpensive, selectivity-enhancing, alkali-metal-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

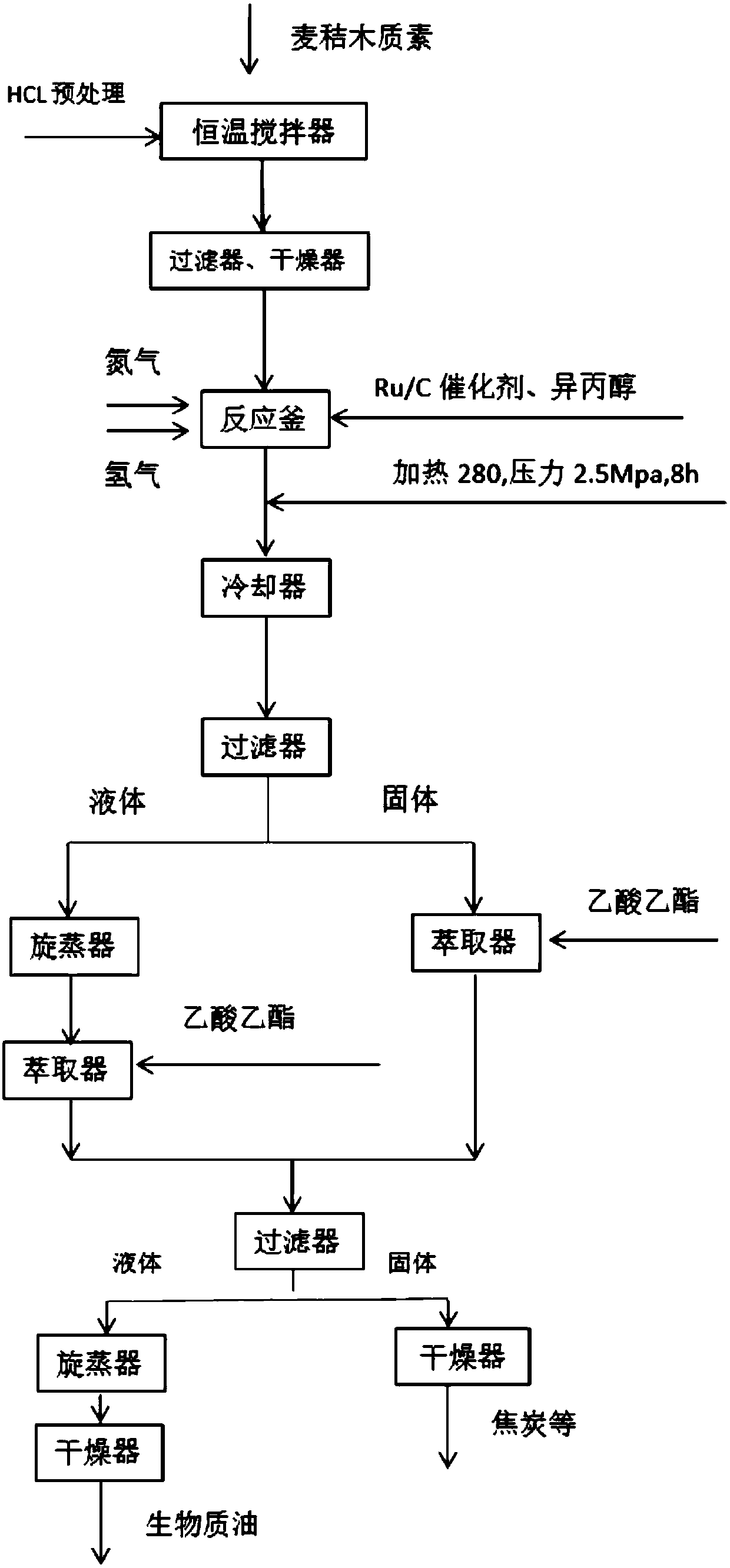

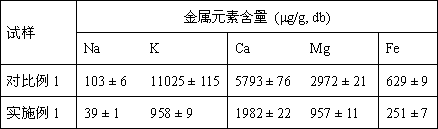

[0025] 1) Grind wheat straw lignin to 40 mesh, sieve, take 100g into a beaker containing 2L hydrochloric acid solution (pH=3), then stir at 50°C for 2 hours, then filter to obtain solid and wash with deionized water until neutral. Finally, the samples were dried to obtain pretreated lignin. The metal ion content in the pretreated lignin was detected, see Table 1.

[0026] 2) Weigh 50g of treated lignin, add 1g of Ru / C catalyst and mix evenly, then add 160ml of isopropanol, stir evenly and seal the reaction vessel, wherein the Ru content in Ru / C catalyst is 5wt%.

[0027] 3) Feed in nitrogen to drive away the air in the reactor, feed in hydrogen to drive away the nitrogen in the reactor, finally feed in hydrogen, and keep the pressure to 2.5Mpa.

[0028] 4) React at 280°C for 8 hours, put the reaction kettle into a cooler to cool, and filter the solution in the kettle to obtain solids and liquids after cooling.

[0029] 5) Add the obtained liquid to a rotary evaporator to ev...

Embodiment 2

[0036] 1) Grind wheat straw lignin to 40 mesh, sieve, take 100g into a beaker containing 2L hydrochloric acid solution (pH=3), then stir at 50°C for 2 hours, then filter to obtain solid and wash with deionized water until neutral. Finally, the samples were dried to obtain pretreated lignin.

[0037] 2) Weigh 50g of treated lignin, add 1.25g of Ru / C catalyst and mix evenly, add 200ml of isopropanol, stir evenly and seal the reaction vessel, wherein the Ru content in Ru / C catalyst is 8wt%.

[0038] 3) Feed in nitrogen to drive away the air in the reactor, feed in hydrogen to drive away the nitrogen in the reactor, finally feed in hydrogen, and keep the pressure to 2.5Mpa.

[0039] 4) React at 280°C for 6 hours, put the reaction kettle into a cooler to cool, and filter the solution in the kettle to obtain solids and liquids after cooling.

[0040] 5) Add the obtained liquid to a rotary evaporator to evaporate isopropanol, then add ethyl acetate to extract to obtain ethyl acetat...

Embodiment 3

[0047] 1) Grind wheat straw lignin to 40 mesh, sieve, take 100g into a beaker containing 2L hydrochloric acid solution (pH=3), then stir at 50°C for 2 hours, then filter to obtain solid and wash with deionized water until neutral. Finally, the samples were dried to obtain pretreated lignin.

[0048] 2) Weigh 50g of treated lignin, add 1.15g of Ru / C catalyst and mix evenly, heat 180ml of isopropanol, stir evenly and seal the reaction vessel, wherein the Ru content in Ru / C catalyst is 10wt%.

[0049] 3) Feed in nitrogen to drive away the air in the reactor, feed in hydrogen to drive away the nitrogen in the reactor, finally feed in hydrogen, and keep the pressure to 2.5Mpa.

[0050] 4) React at 280°C for 7 hours, put the reaction kettle into a cooler to cool, and filter the solution in the kettle to obtain solids and liquids after cooling.

[0051] 5) Add the obtained liquid to a rotary evaporator to evaporate isopropanol, then add ethyl acetate to extract to obtain ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com