Method for treating iron-containing red mud through coal-based shaft furnace technology

A red mud and shaft furnace technology, applied in the environmental protection field of comprehensive utilization of red mud resources, can solve the problems of increased difficulty in blast furnace smelting operations, bottlenecks in large-scale production, low metallization rate, etc., and achieve advanced and reliable production technology and high product quality The effect of stability and high ball strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

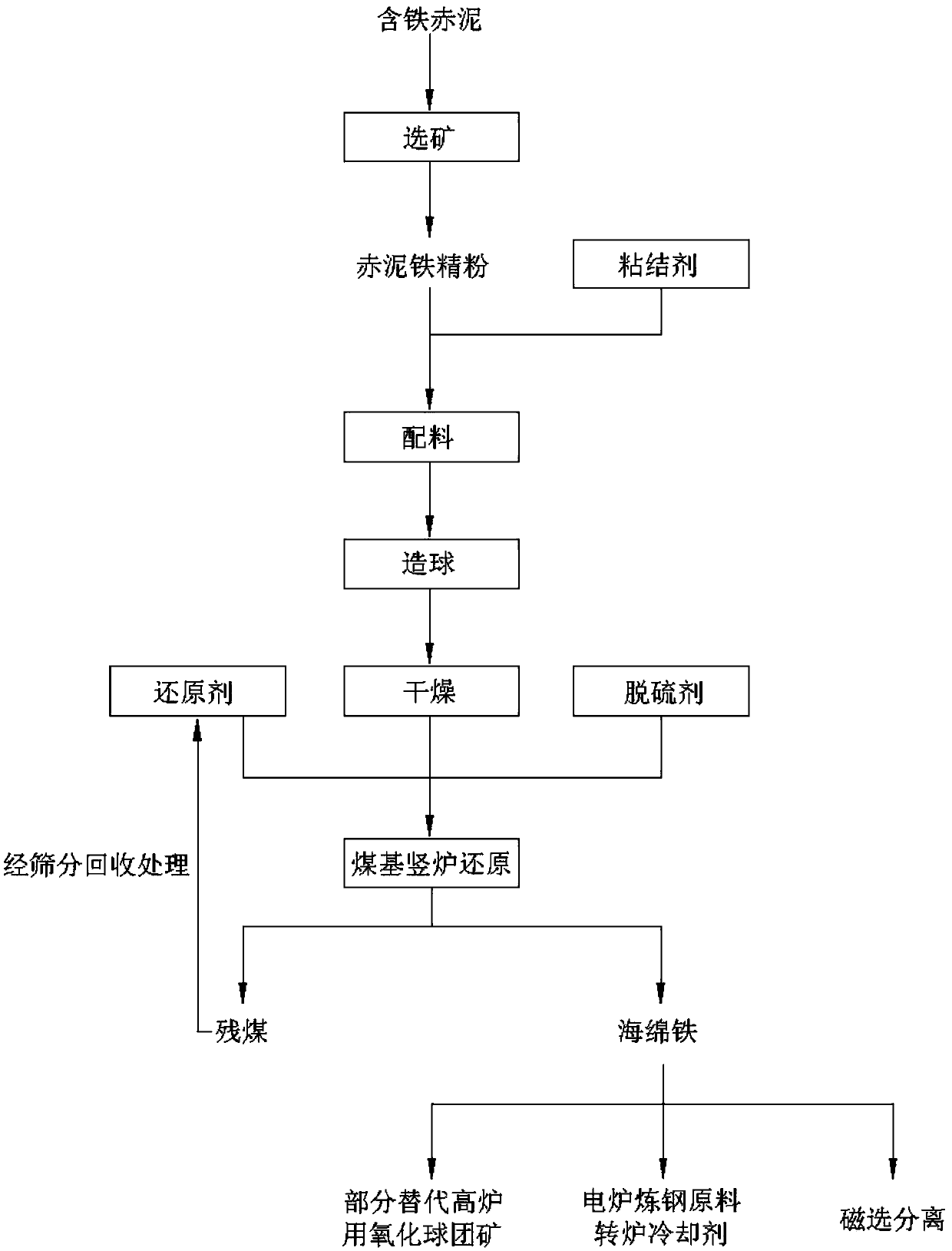

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of method of coal-based shaft furnace process iron-containing red mud, its steps are:

[0030] (1) The iron-containing red mud raw ore is ground, separated by high-gradient magnetic separation, and dried to obtain tailings and red mud iron powder; the water content of the red mud iron powder is ≤8%, and the particle size is less than 100 mesh.

[0031] The typical composition of red mud iron fine powder after beneficiation is as follows (mass content %):

[0032] TF

S

P

TiO 2

47.25

0.04

0.1

5.68

[0033] (2) In the red mud iron concentrate powder, a binder (the binder is a mixture of lignocellulose and molasses, lignocellulose: syrup=0.5:0.5), Add 2-5% water, mix well and press the ball, the diameter of the raw ball is 12-35mm, and the water content is less than 12%;

[0034] (3) After drying, the water content of the green pellets is less than 5%, and the anthracite with a particle size of less than 5mm, a...

Embodiment 2

[0045] Embodiment 2: a kind of method of coal-based shaft furnace process iron-containing red mud, its steps are:

[0046] (1) The iron-containing red mud raw ore is ground, separated by high-gradient magnetic separation, and dried to obtain tailings and red mud iron powder; the water content of the red mud iron powder is ≤8%, and the particle size is less than 100 mesh.

[0047] The typical composition of red mud iron fine powder after beneficiation is as follows (mass content %):

[0048] TF

S

P

TiO 2

47.25

0.04

0.1

5.68

[0049] (2) In the red mud iron concentrate powder, a binder (the binder is a mixture of lignocellulose and molasses, lignocellulose: syrup=0.5:0.5), Add 2-5% water, mix well and press the ball, the diameter of the raw ball is 12-35mm, and the water content is less than 12%;

[0050] (3) After drying, the water content of the green pellets is less than 5%, and the anthracite with a particle size of less than 5mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com