Biomass circulating fluidized bed direct-fired boiler and system coupling same with gasifier for power generation and coproduction of activated carbon

A circulating fluidized bed and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low energy utilization rate of biomass raw materials, sintering of bed materials, etc., to increase product added value, reduce high-temperature corrosion, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

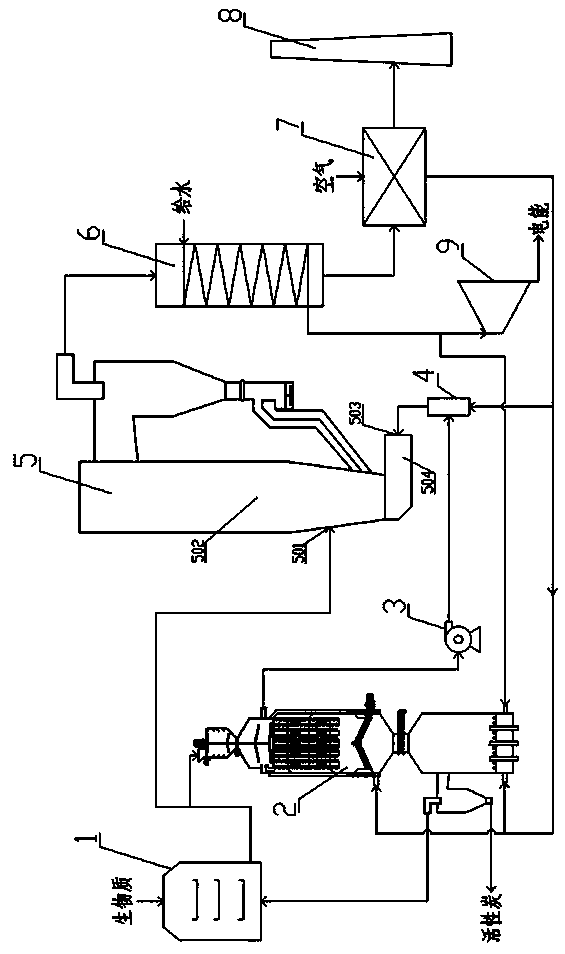

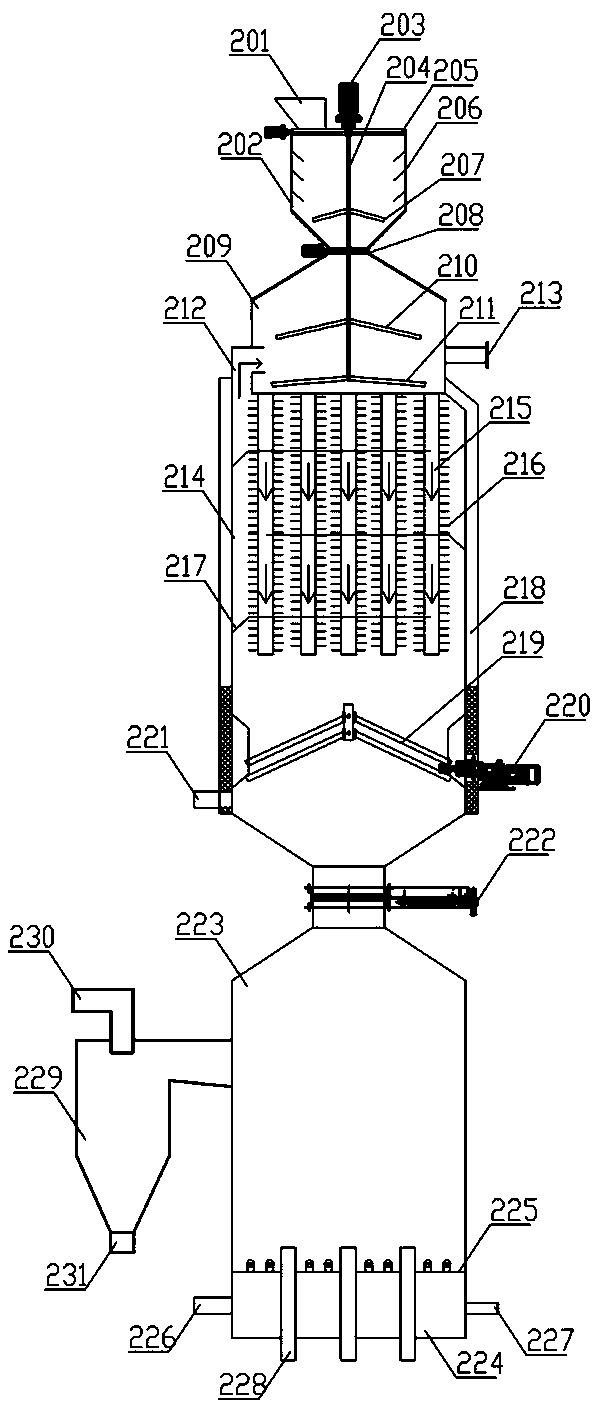

[0045] Such as Figure 1-3 As shown, a biomass circulating fluidized bed direct-fired boiler and its system for generating activated carbon coupled with a gasifier for power generation and co-generation of activated carbon of the present invention uses a gasifier to gasify biomass, and the gasified gas produced is sent to the biomass cycle Coupling power generation in a fluidized bed direct-fired boiler, the biomass carbon produced is activated to obtain activated carbon.

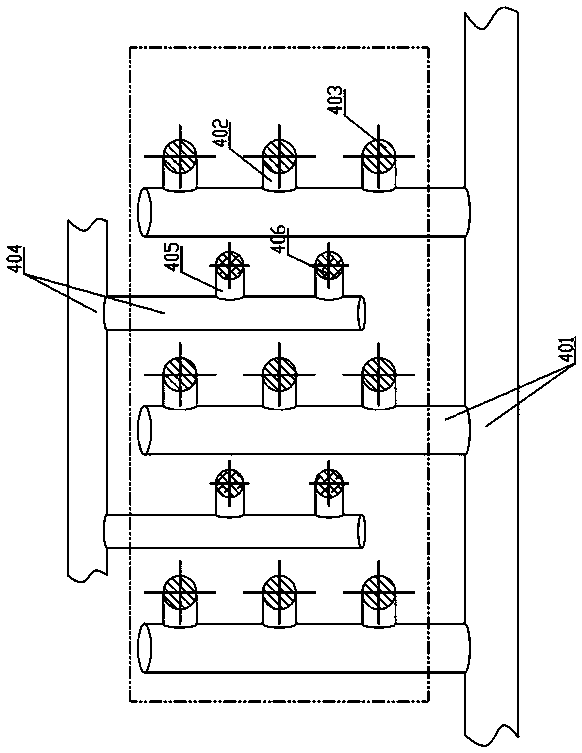

[0046] The biomass circulating fluidized bed direct-fired boiler 5 of the present invention includes a biomass feed port 501, a furnace 502, a gas inlet 503, and a fluidized air chamber 504. The fluidized air chamber 504 is connected to gas through the gas inlet 503 The auxiliary combustion equipment 4 includes the existing pre-combustion chamber of the boiler. The auxiliary gas combustion equipment 4 is installed on both sides of the original pre-combustion chamber of the fluidized air chamber 504. It consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com