Multifunctional acrylic ester emulsion

An acrylate and multi-functional technology, applied in the field of emulsion, can solve the problem of single function, etc., and achieve the effect of high tensile strength, good waterproof effect, and small shrinkage of mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

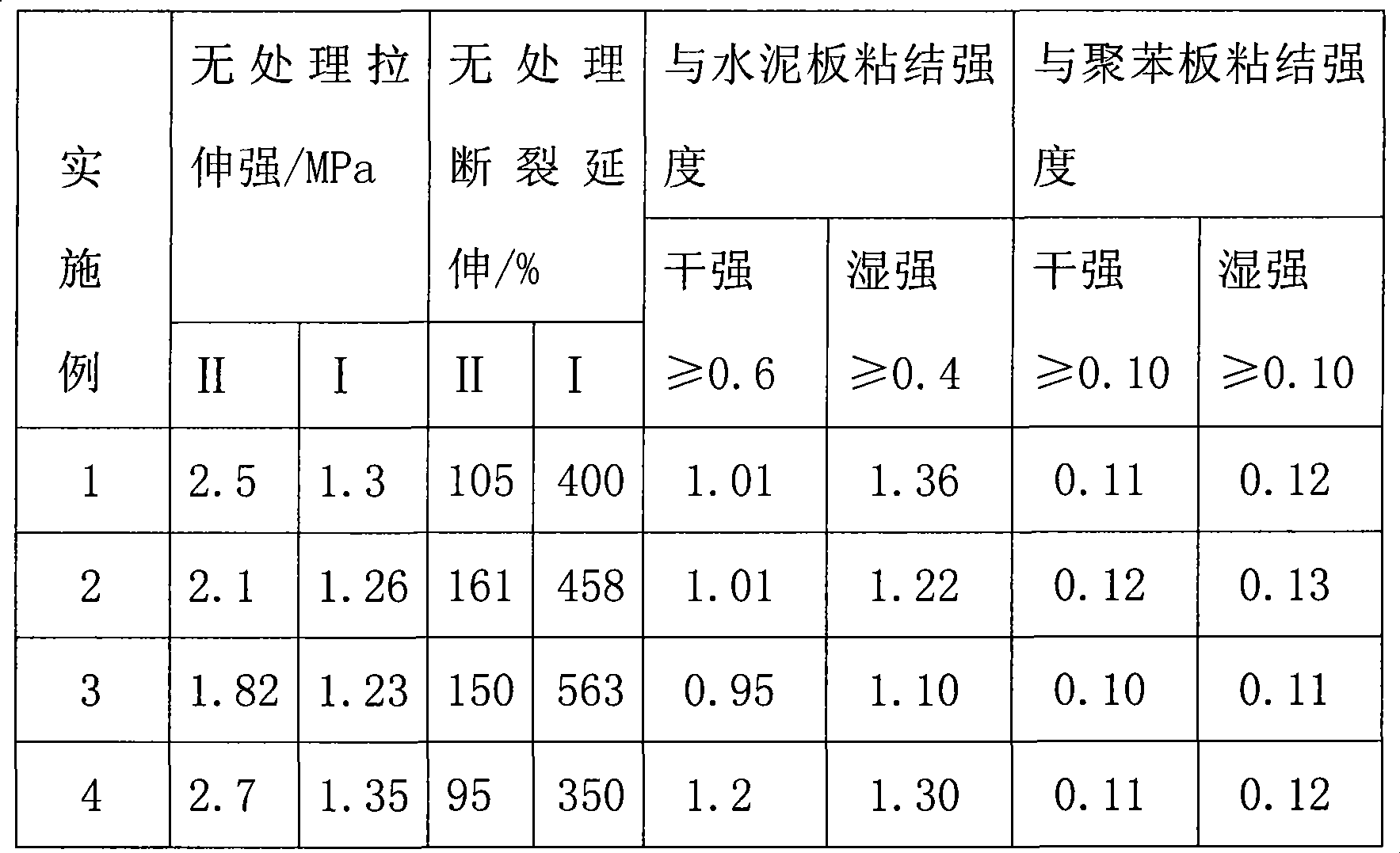

Examples

Embodiment 1

[0027] Preparation of pre-emulsion: 192 grams of deionized water, 9.62 grams of nonylphenol polyoxyethylene ether (NP-10), 12.04 grams of dodecyl diphenyl ether disulfonic acid sodium salt (DOWFAX2A1), 5.42 grams of vinyl sulfonate Sodium sulfonate (SVS), 10.85 grams of allyl hydroxypropyl sodium sulfonate (COPS-1) were stirred and dissolved in the pre-emulsification tank, and then 2.17 grams of vinyltriethoxysilane (A-151), After adding 5.42 grams of N-methylolacrylamide, 8.14 grams of acrylic acid, 357.97 grams of butyl acrylate, 116.61 grams of styrene, and 54.24 grams of methyl methacrylate, continue stirring for 30 minutes to obtain a pre-emulsion.

[0028] Preparation of initiator solution: 81.36 grams of deionized water, 2.44 grams of ammonium persulfate and 2.44 grams of sodium bicarbonate were stirred and dissolved to obtain an initiator solution.

[0029] 130.71 grams of deionized water, 0.37 grams of ammonium persulfate, 0.51 grams of nonylphenol polyoxyethylene eth...

Embodiment 2

[0031] Preparation of pre-emulsion: 192 grams of deionized water, 9.62 grams of alkyl alcohol polyether type nonionic (A-980), 12.04 grams of ethoxylated ammonium sulfate (CO-436), 5.42 grams of sodium vinyl sulfonate (SVS), 10.85 grams of allyl hydroxypropyl sodium sulfonate (COPS-1) was stirred and dissolved in the pre-emulsification tank, and then 2.17 grams of A-151, 5.42 grams of acrylamide, 8.14 grams of methacrylic acid, After the addition of 357.97 grams of butyl acrylate and 170.85 grams of styrene was completed, the stirring was continued for 30 minutes to obtain a pre-emulsion.

[0032] Prepare the initiator solution: 81.36 grams of deionized water, 2.44 grams of ammonium persulfate, and 2.44 grams of sodium bicarbonate were stirred and dissolved to obtain the initiator solution.

[0033] Add 130.71 grams of deionized water, 0.37 grams of ammonium persulfate, 0.51 grams of alkyl alcohol polyether type nonionic (A-980), 0.64 grams of ethoxylated phenol ether ammonium...

Embodiment 3

[0035] Preparation of pre-emulsion: 192 grams of deionized water, 9.62 grams of alkyl alcohol polyether type nonionic (A-980), 12.04 grams of ethoxylated ammonium sulfate (CO-436), 5.42 grams of sodium vinyl sulfonate (SVS), 10.85 grams of allyl hydroxypropyl sodium sulfonate (COPS-1) was stirred and dissolved in the pre-emulsification tank, and then 2.17 grams of 3-aminopropyltriethoxysilane (KH-550) was added under stirring , 5.42 grams of N-methylolacrylamide, 8.14 grams of methacrylic acid, 78.85 grams of ethyl acrylate, 300 grams of isooctyl acrylate, and 150 grams of methyl methacrylate. After the addition, continue to stir for 30 minutes to obtain pre-emulsified liquid.

[0036]Prepare the initiator solution: 81.36 grams of deionized water, 2.44 grams of ammonium persulfate, and 2.44 grams of sodium bicarbonate were stirred and dissolved to obtain the initiator solution.

[0037] Add 130.71 grams of deionized water, 0.37 grams of ammonium persulfate, 0.51 grams of alky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com