Long and thin-walled tube induction hardening deformation control device

A technology of induction quenching and deformation control, applied in quenching devices, manufacturing tools, furnaces, etc., to achieve the effect of simple process, strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

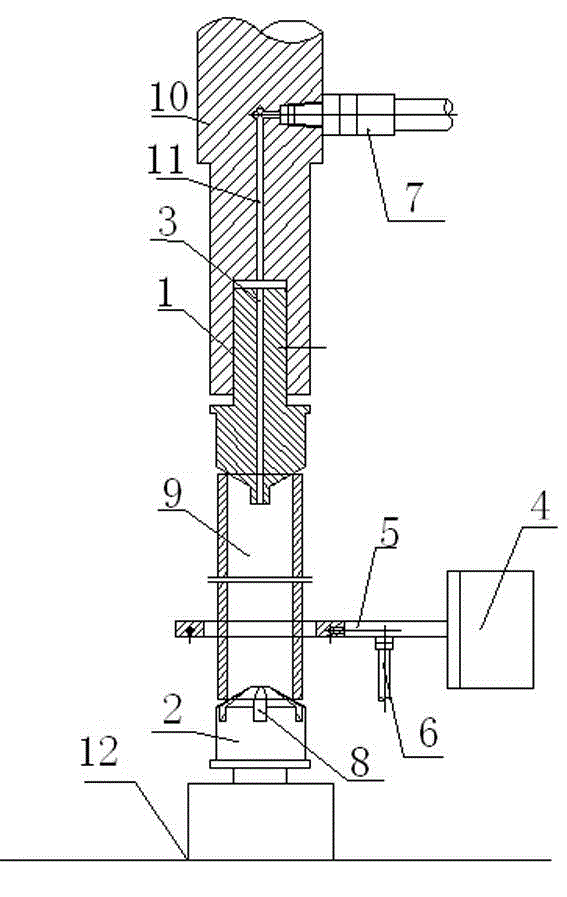

[0016] The invention is like figure 1 Shown.

[0017] The slender and thin-walled tube induction hardening deformation control device includes a pressure rod 10 and an equipment base 12, the pressure rod 10 is above the equipment base 12, the pressure rod 10 is provided with a water hole 11, and the side wall of the pressure rod 10 is provided with cooling Liquid inlet 7; the lower end of the pressure rod 10 is provided with an upper pressure head 1, and the upper pressure head 1 is provided with a water outlet hole 3, which corresponds to the water hole 11; the equipment base 12 corresponds to the upper pressure head 1 with a lower pressure head 2 Another induction electrode 4 is provided on the equipment base 12, the induction electrode 4 is connected with an induction coil 5, the induction coil 5 moves up and down between the upper indenter 1 and the lower indenter 2, and the inductive coil 5 is connected to the coolant water pipe 6 .

[0018] The upper indenter 1 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com