Induction quenching method of gearshift shaft of change gear case

An induction quenching and shifting fork technology, applied in the field of gearbox shifting fork shaft processing, can solve the problems of increased brittleness of parts, improper handling, brittle fracture, etc., to meet the performance requirements, simple structure and process, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

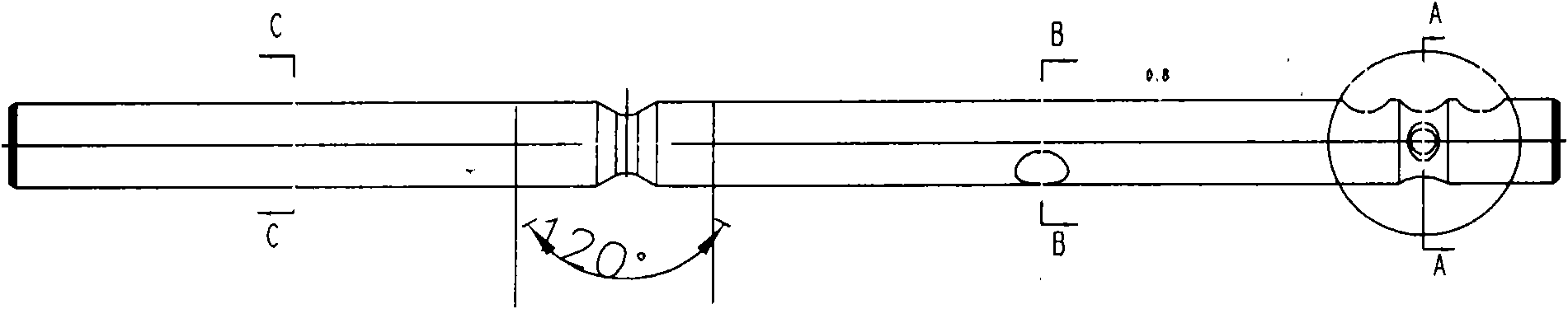

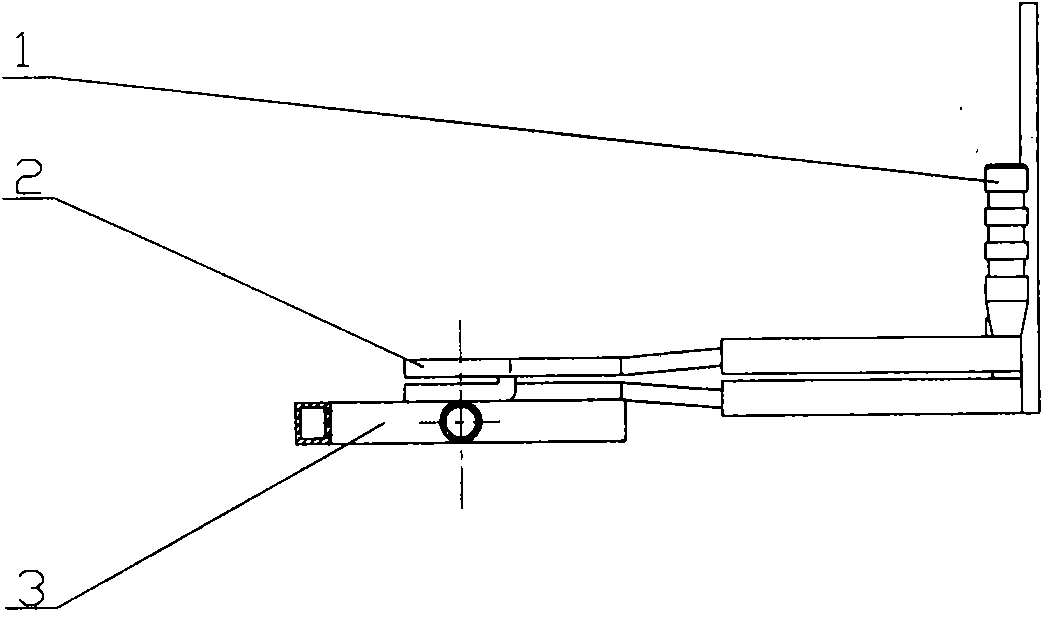

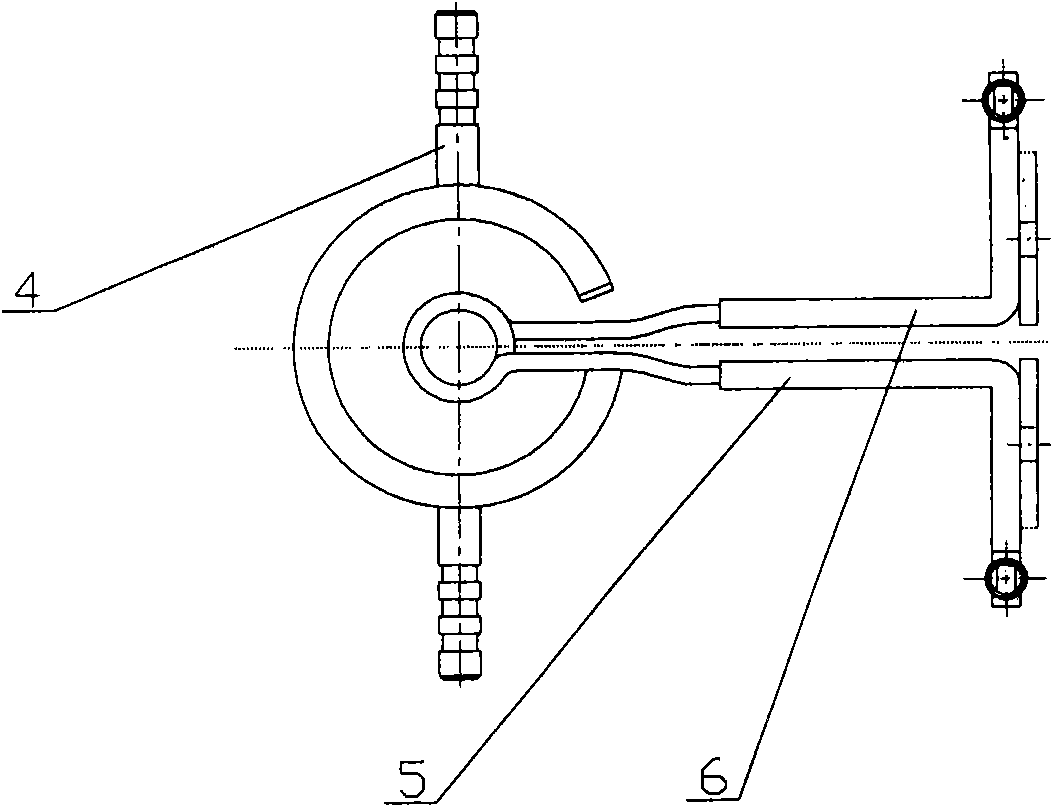

[0012] Shift fork shaft 1, reverse gear

[0013] Shift fork shaft 2, 3, gear

[0014] Shift fork shaft 4, 5, gear

[0015] Part number: 1702041-A7G

[0016] 1702036-A7G

[0017] 1702031-A7G

[0018] Induction hardening technical requirements:

[0019] Material: 45A08M-12.2

[0020] Pre-heat treatment: quenching and tempering 223~254HBW according to A08M-7.1

[0021] Induction hardening area: surface hardness 56~62HRC according to A08M-8.2

[0022] Effective hardened layer depth DS450HV51.0~3.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com