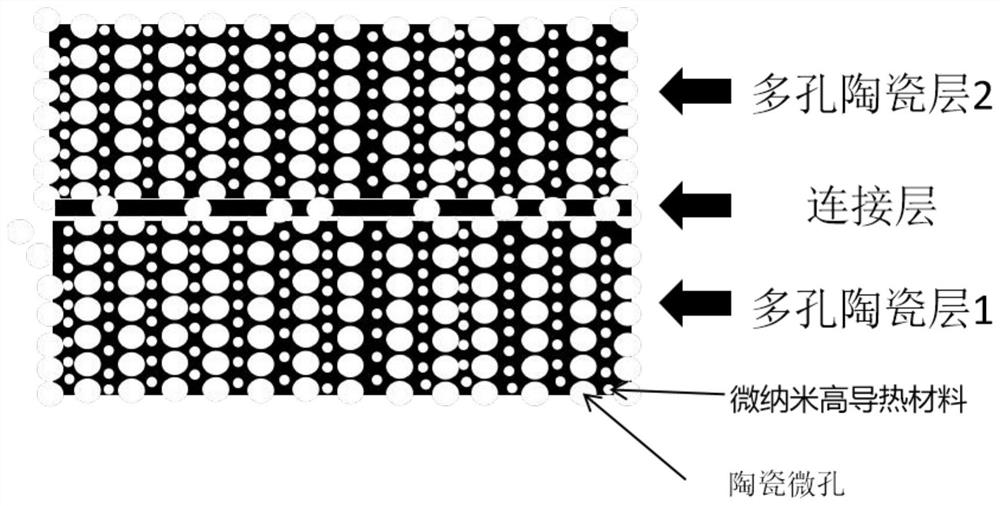

Multi-layer porous ceramic material and preparation method thereof

A technology of porous ceramics and ceramic powders, applied in the field of atomizers, can solve the problems of inconsistent heat transmission, uneven distribution, weak oil-locking and oil-conducting ability, etc. Loss and increase the effect of oil locking and oil guiding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]On the other hand, there is also provided a method for preparing a multilayer porous ceramic material, the method comprising:

[0041]Ceramic powder, additives, co-solvents, pore formers and nano-high thermal conductivity materials are made into ceramic bodies through ball milling, granulation, and cold forming processes;

[0042]Use ceramic powder, additives, pore formers and nano high thermal conductivity materials to press into ceramic slurry;

[0043]The ceramic slurry and the ceramic body are alternately distributed in sequence to obtain the pre-composite material;

[0044]The pre-composite material is sintered to prepare a multilayer porous ceramic composite material.

[0045]In the foregoing embodiment, in the method for preparing composite porous ceramics, the ceramic powder is at least one of alumina, zirconia, silicon oxide, yttrium oxide, silicon carbide, boron nitride, aluminum nitride, silicon nitride, etc., Ceramic powder particle size D50It is 1μm~30μm. Additives include alumi...

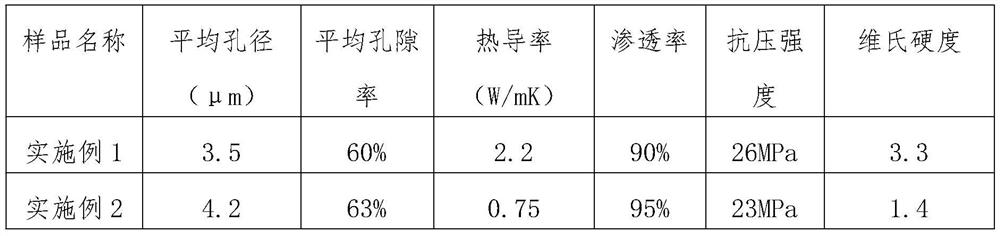

Embodiment 1

[0050](1) Take a certain amount of alumina powder, powder particle size D505μm, 8wt% SiO2, 8wt% hollow zirconia, 5wt% ammonium dihydrogen phosphate, 3wt% TiO2And 3wt% MgO2, 3wt% Al-Mg-Cu alloy powder, 65%wt% absolute ethanol, the above raw materials can be milled using a ball mill, the milling time is 2h, and the speed is 200r / min.

[0051](2) Dry the above ball mill slurry at 120°C to obtain the dried ceramic powder. Add a certain amount of 5% PVA solution, and then granulate. There is no special requirement for the granulation particle size, which can ensure that the cold compacted body has Certain strength, no stratification, no defects, etc.

[0052](3) Use cold isostatic pressing or other molding methods to make ceramic green bodies from the granulated powder.

[0053](4) Take a certain amount of alumina powder, powder particle size D505μm, 5wt% SiO2, 5wt% hollow alumina, 5wt% ammonium dihydrogen phosphate, 3wt% TiO2And 3wt% MgO2, 5wt% Al-Mg-Cu alloy powder, 50%wt% absolute ethanol, 40w...

Embodiment 2

[0057](1) Take a certain amount of ZrO2Powder, powder particle size D505μm, 8wt% SiO2, 8wt% hollow glass powder, 5wt% ammonia dihydrogen phosphate, 3wt% Al-Mg-Cu alloy powder, 3wt% TiO2And 3wt% MgO2, 65% wt% absolute ethanol, the above raw materials can be milled using a ball mill, the milling time is 2h, and the speed is 200r / min.

[0058](2) Dry the above ball mill slurry at 120°C to obtain the dried ceramic powder. Add a certain amount of 5% PVA solution, and then granulate. There is no special requirement for the granulation particle size, which can ensure that the cold compacted body has Certain strength, no stratification, no defects, etc.

[0059](3) Use cold isostatic pressing or other molding methods to make ceramic green bodies from the granulated powder.

[0060](4) Take a certain amount of Si3N4Powder, powder particle size D505μm, 5wt% SiO2, 5wt% hollow glass powder, 5wt% ammonia dihydrogen phosphate, 5wt% Cu-Ni-Zn alloy powder, 3wt% TiO2And 3wt% MgO2, 50%wt% absolute ethanol, 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com