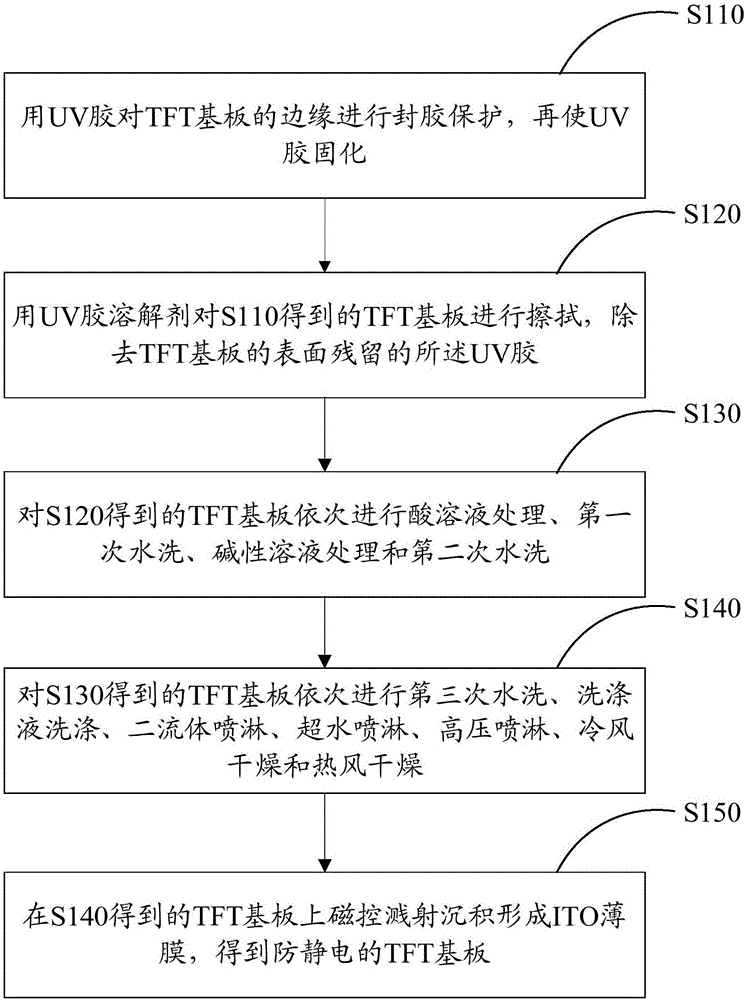

Process for producing antistatic TFT substrate

A production process, anti-static technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problem of poor anti-static effect of TFT-type liquid crystal display, easy detachment of anti-static film, surface oxides, glue, oil stains, etc. Problems such as excessive dust residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The edge of the TFT substrate to be treated is sealed and protected with UV glue, and then the UV glue is cured. The thickness of the TFT substrate is 1 mm. Put the sealed TFT substrate into a UV curing machine at a temperature of 60 ° C. Use ultraviolet rays to irradiate the TFT substrate with UV glue and UV glue for 30 minutes.

[0055] Use a dust-free cloth dipped in acetone to wipe on the surface of the cured TFT substrate to remove the UV glue remaining on the surface of the cured TFT substrate.

[0056] The sealed TFT substrate is sequentially subjected to acid solution treatment, first water washing, alkaline solution treatment and second water washing. The TFT substrate was placed in an acid tank containing a mixed solution of 70% sulfuric acid solution and 30% hydrofluoric acid solution (volume ratio 600:1), soaked for 60min, and the temperature was 30°C. There is a bubbling tube at the bottom of the acid tank, the bubbling makes the pickling accelerated and u...

Embodiment 2

[0063] The edge of the TFT substrate to be treated is sealed and protected with UV glue, and then the UV glue is cured. The thickness of the TFT substrate is 1.4 mm. Put the glue-sealed TFT substrate into a UV curing machine at a temperature of 55 ° C. Use ultraviolet rays to irradiate the TFT substrate with UV glue and UV glue for 25 minutes.

[0064] Use a dust-free cloth dipped in acetone to wipe on the surface of the cured TFT substrate to remove the UV glue remaining on the surface of the cured TFT substrate.

[0065] The sealed TFT substrate is sequentially subjected to acid solution treatment, first water washing, alkaline solution treatment and second water washing. The TFT substrate was placed in an acid tank containing a mixed solution of 70% sulfuric acid solution and 30% hydrofluoric acid solution (volume ratio 300:1), soaked for 70 minutes, and the temperature was 25°C. The bottom of the acid tank is equipped with a bubbling tube, the bubbling makes the pickling ...

Embodiment 3

[0072] The edge of the TFT substrate to be treated is sealed and protected with UV glue, and then the UV glue is cured. The thickness of the TFT substrate is 1.2mm. Put the sealed TFT substrate into a UV curing machine at a temperature of 58°C. Use ultraviolet rays to irradiate the TFT substrate with UV glue and the UV glue for 28 minutes.

[0073] Use a dust-free cloth dipped in acetone to wipe on the surface of the cured TFT substrate to remove the UV glue remaining on the surface of the cured TFT substrate.

[0074] The sealed TFT substrate is sequentially subjected to acid solution treatment, first water washing, alkaline solution treatment and second water washing. The TFT substrate was placed in an acid tank containing a mixed solution of 70% sulfuric acid solution and 30% hydrofluoric acid solution (volume ratio 1000:1), soaked for 50 minutes, and the temperature was 28°C. There is a bubbling tube at the bottom of the acid tank, the bubbling makes the pickling accelera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com