Ink box cleaning method

A technology of ink cartridges and ink chambers, applied in the field of recycling and regeneration of printing consumables, can solve problems such as difficulty in ensuring the adsorption force/purity of porous materials, hidden dangers of color mixing, troublesome operation, etc., to avoid defective flexible printed circuit boards, protect service life, and avoid Effects of water pressure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

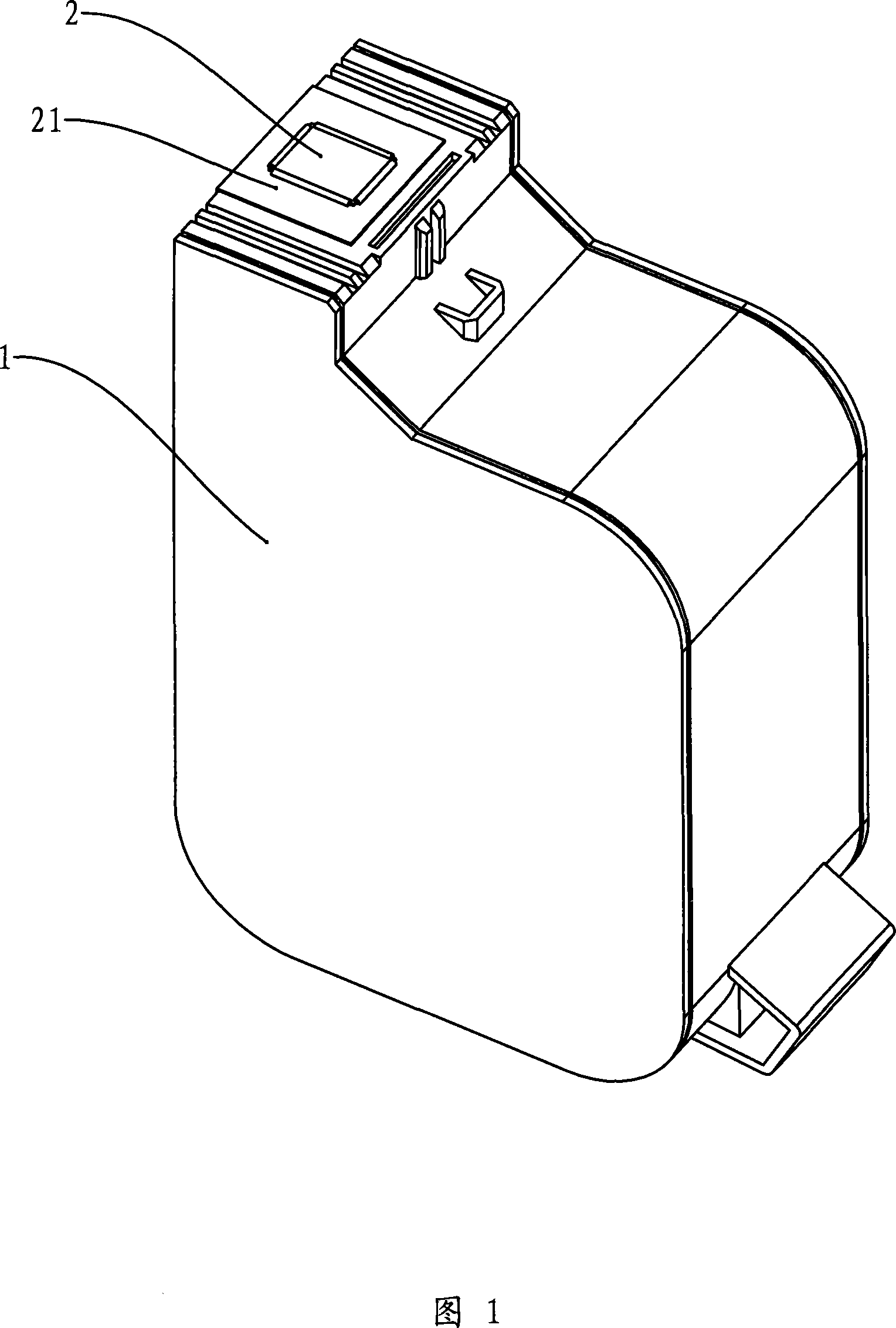

[0027] A method for regenerating ink cartridges, comprising the steps of:

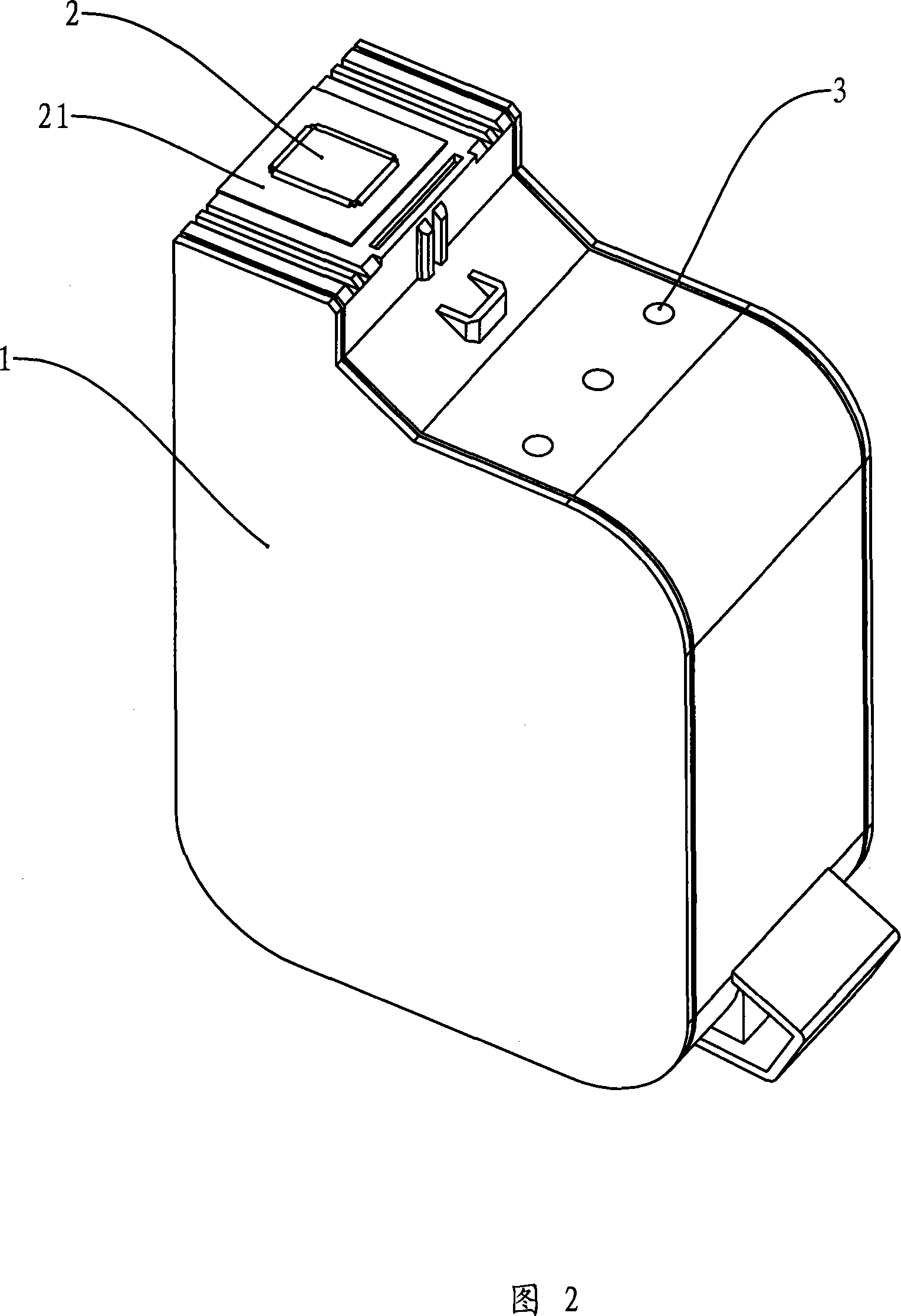

[0028] (1) Referring to Figure 2, three pressure relief holes 3 with a diameter of 1-3mm are opened at the bottom of the ink cartridge;

[0029] (2) Positive pressure injection of warm water with a temperature of 20°C-50°C from the top ink filling port, so that the warm water flows out from the pressure relief hole 3 and the ink outlet of the ink cartridge at the same time. Generally, it is better to clean until the water flowing out is clear and transparent;

[0030] (3) Use a centrifugal dehydrator to dehydrate and reset, and the speed of the centrifugal dehydrator is controlled at 1000 rpm-3000 rpm;

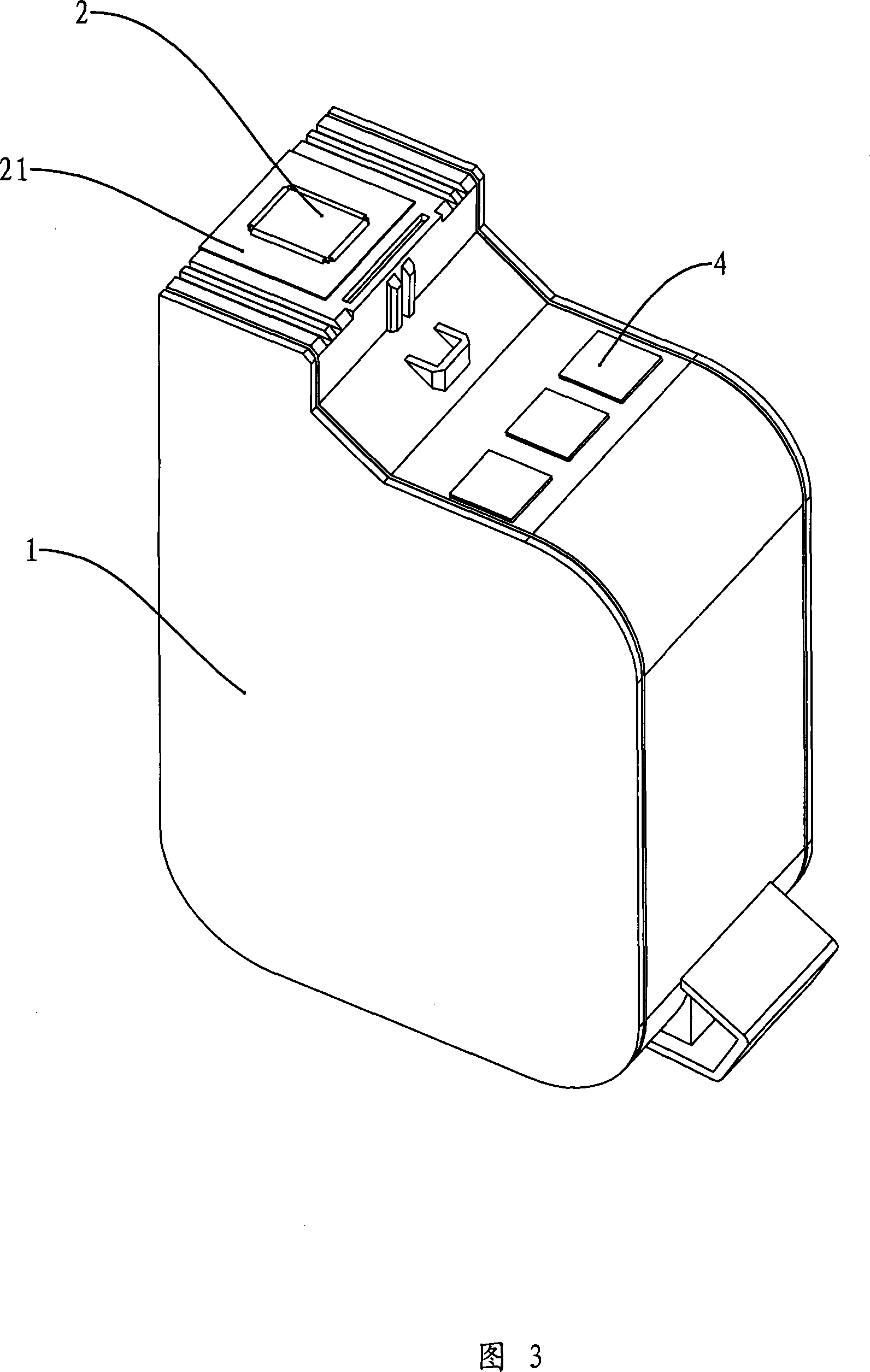

[0031] (4) Dry porous materials. The specific drying method can be realized in the following two ways: ①Insert the needle tube from the ink injection hole on the top, and the needle tube head is 9-12mm away from the filter screen, and the temperature is 10-50°C. Dry to the rated weight; ②Put the ink c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com