Gap adjusting device, ink-jet printer and modification method thereo

A technology for gap adjustment devices and inkjet printers, applied to power transmission devices, printing, transfer materials, etc., can solve the problems of thick recording media, inconvenience for users, and affecting printing quality, etc., achieve low modification costs, improve column print quality, increase the effect of adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

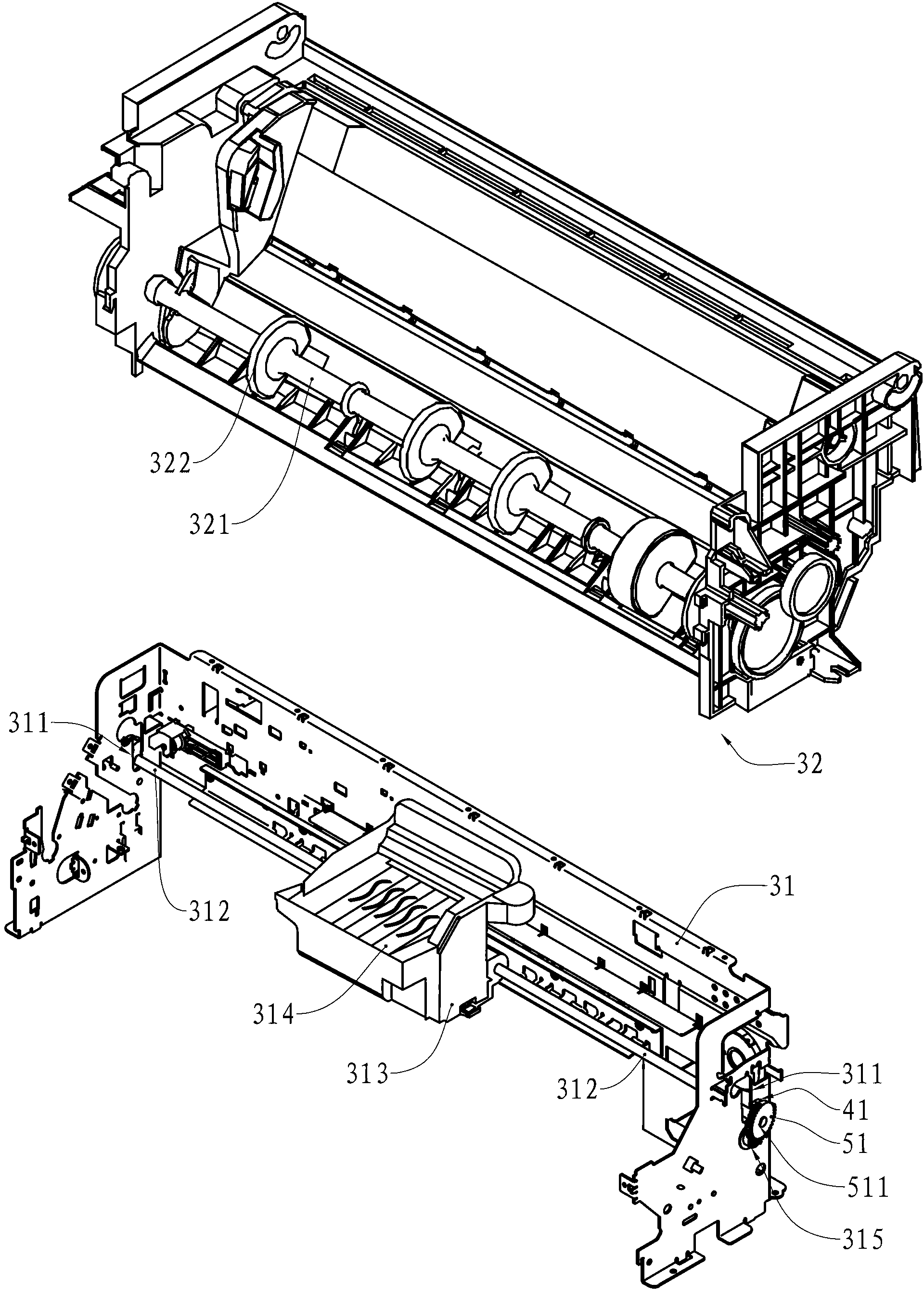

[0035] refer to Figure 7 , Figure 7 It is an exploded view of the structure of the inkjet printer embodiment of the present invention after removing the shell. A body frame 71 and a paper feed frame 72 are arranged inside the inkjet printer casing, and the paper feed frame 72 includes a paper feed shaft 721 .

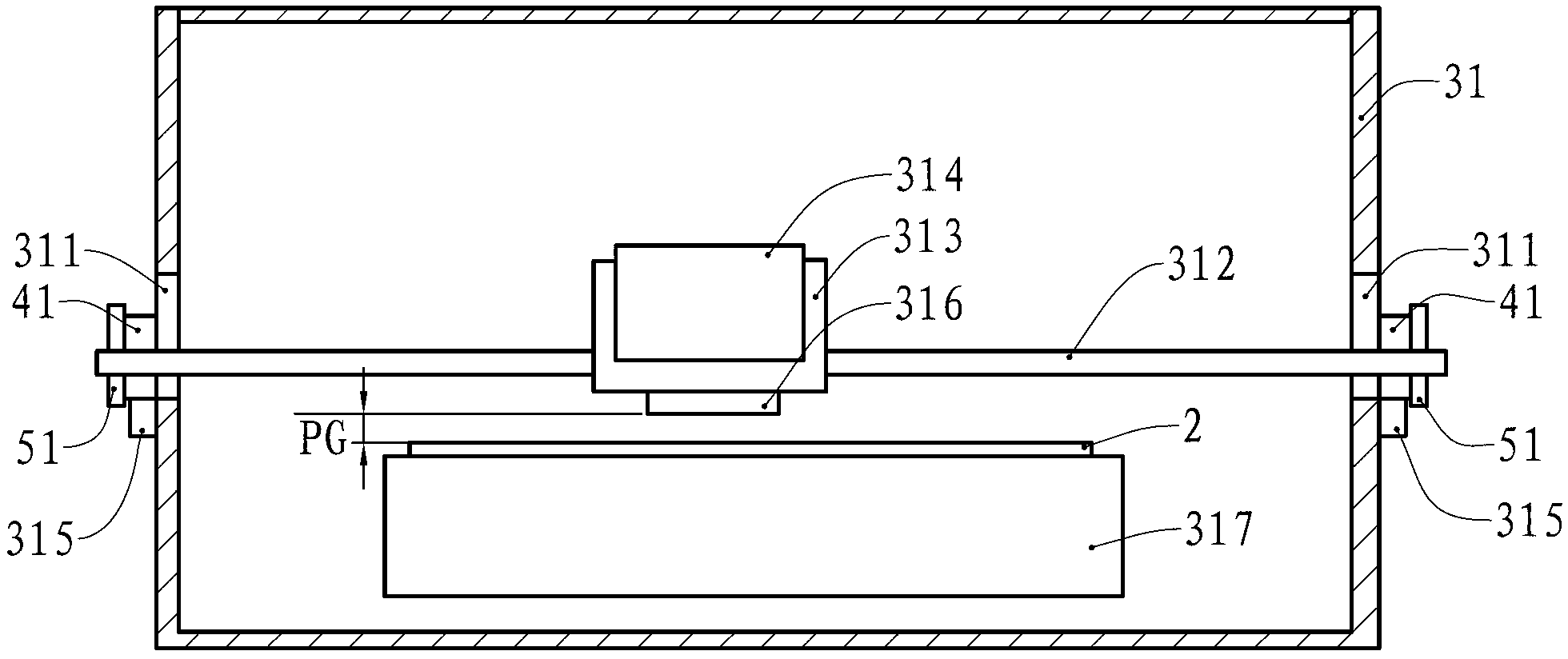

[0036] Two guide holes 711 are respectively provided on the two side walls of the body frame 71 , and the two ends of the guide rod 712 respectively pass through the guide hole 711 , and the guide rod 712 can move within the range limited by the guide hole 711 .

[0037] A character cart 713 is installed on the guide rod 712 , and a plurality of ink cartridges 714 are installed on the character cart 713 , and the character cart 713 can move back and forth along the guide rod 712 . A cam 81 is respectively installed at the two ends of the guide rod 712, as Figure 8As shown, a shaft hole 811 is provided in the middle of the cam 81 , the shaft hole 811 is a through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com