Printing correction unit and method for ink gun

A correction method and technology for a correction device, which are applied to printing devices, printing and other directions, can solve the problems of reducing printing speed, affecting printing speed, increasing printer cost, etc., and achieving the effect of improving printing skew and improving printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specially enumerated below, and in conjunction with the attached drawings, the detailed description is as follows:

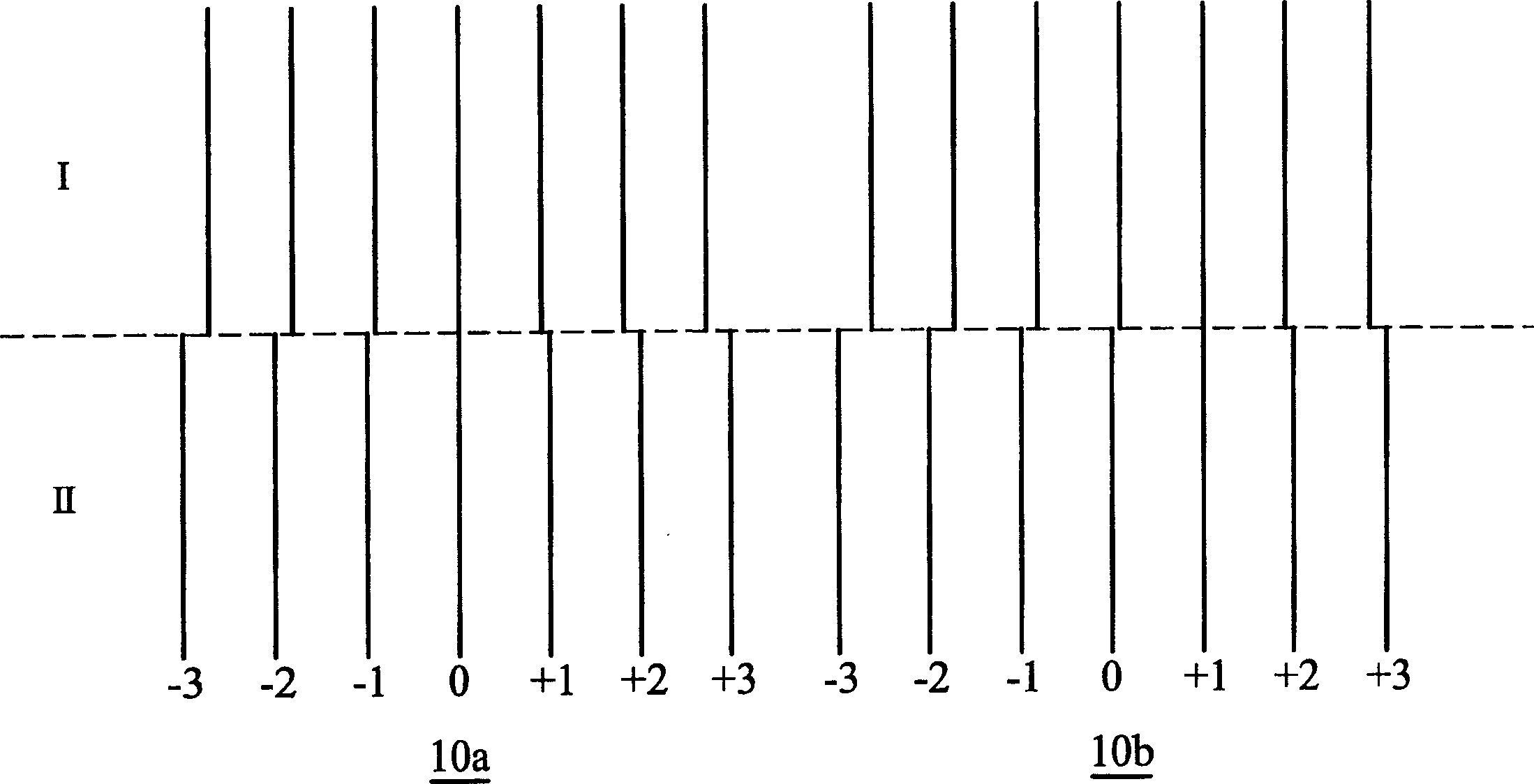

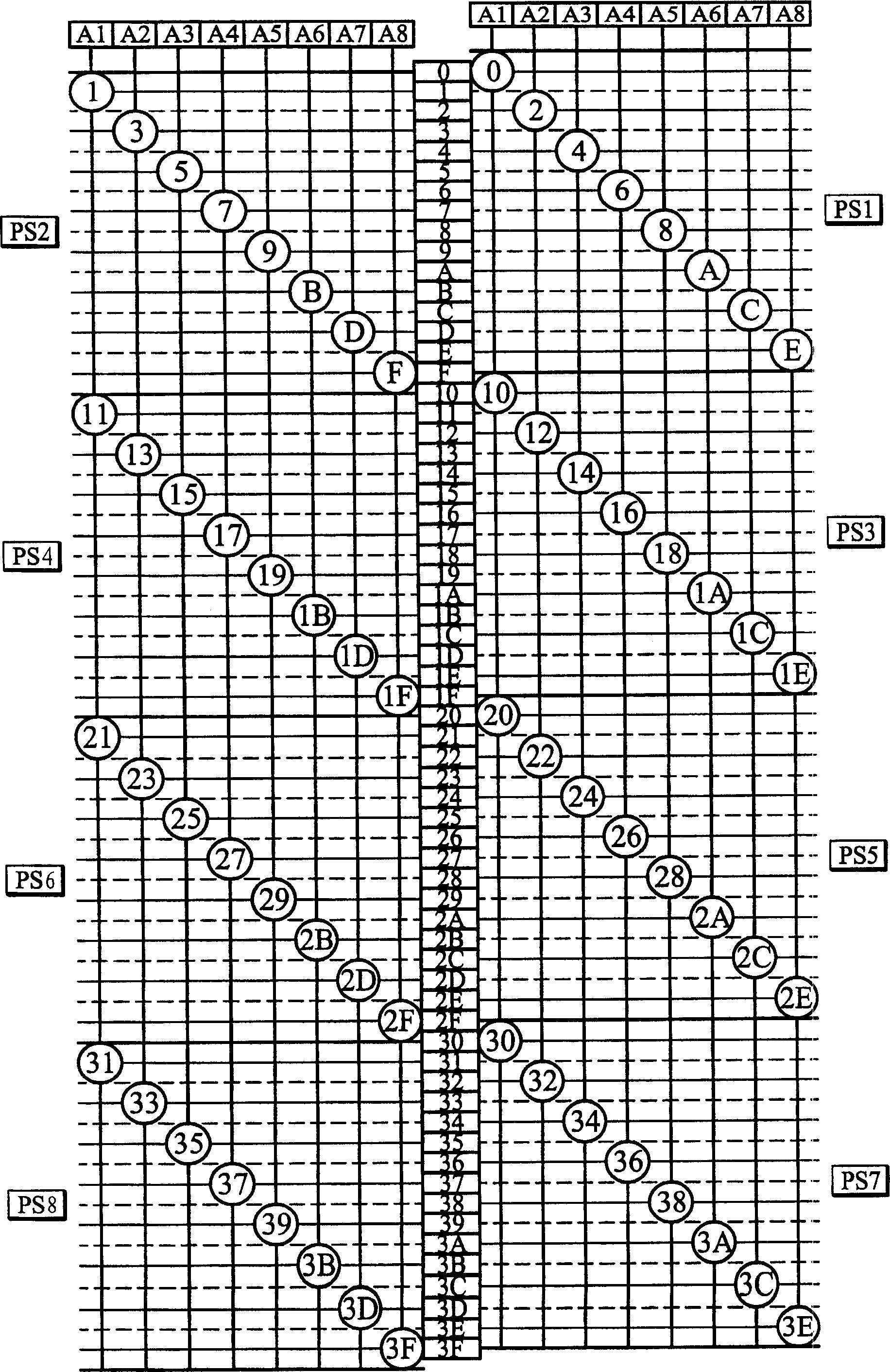

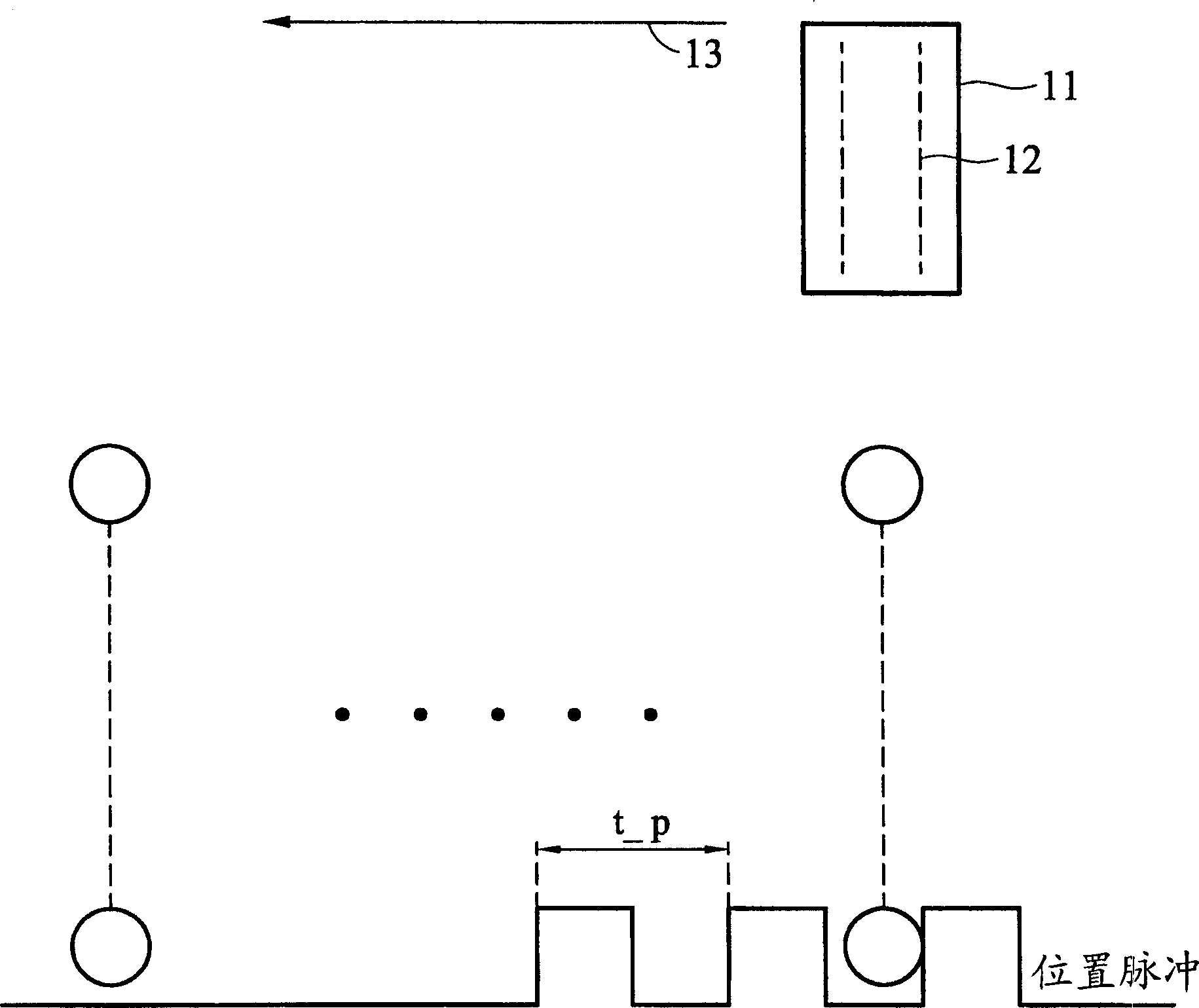

[0045] Figure 1a is a schematic diagram of inkjet image skew detection, where 10a It is the graphic printed by the inkjet head after receiving a test print data under normal circumstances, and 10b It is the graph printed after receiving a test print data under the condition that the inkjet head is skewed. exist Figure 1a Among them, area I is the printing situation where the inkjet head does not receive any displacement correction, and area II is the printing after the inkjet head receives different displacements in the rightward or leftward displacement direction and does not receive any displacement. result. In this figure, the inkjet head receives one, two, and three d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com