Robot printing sample-making system

A robot and printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low automation level, achieve the effect of improving printing quality and realizing standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

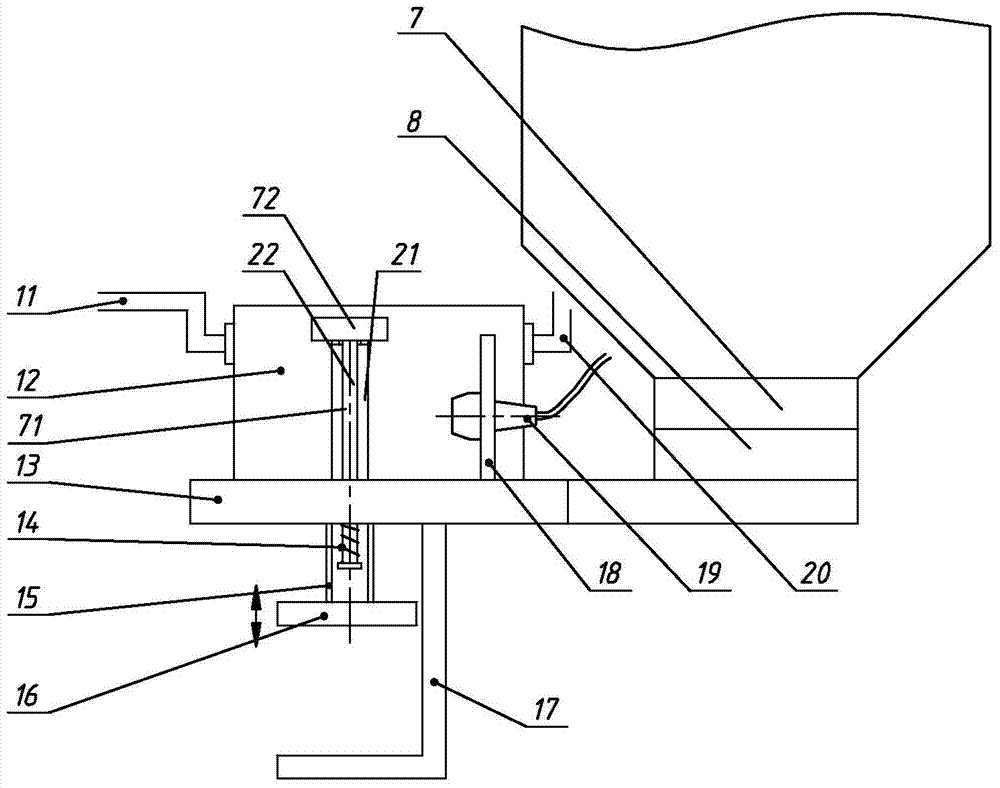

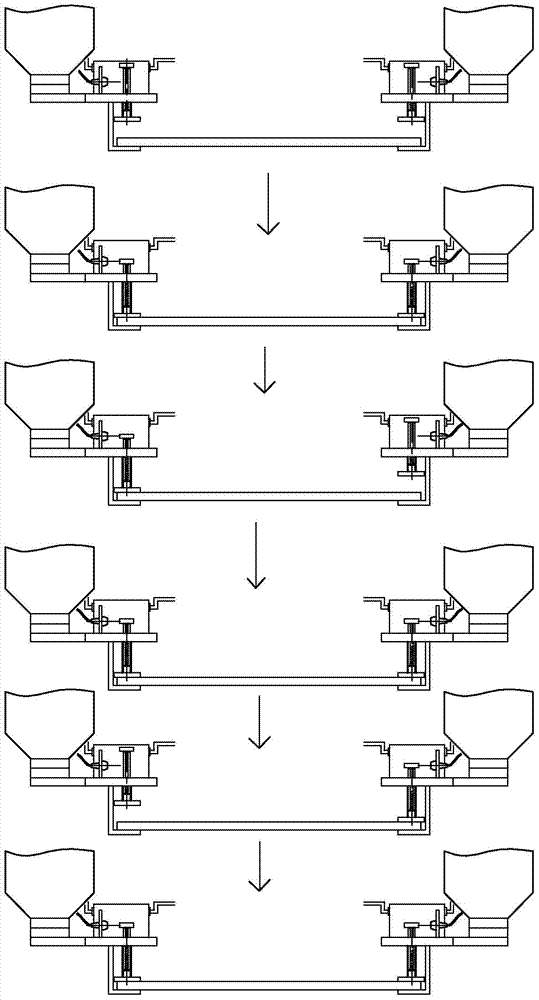

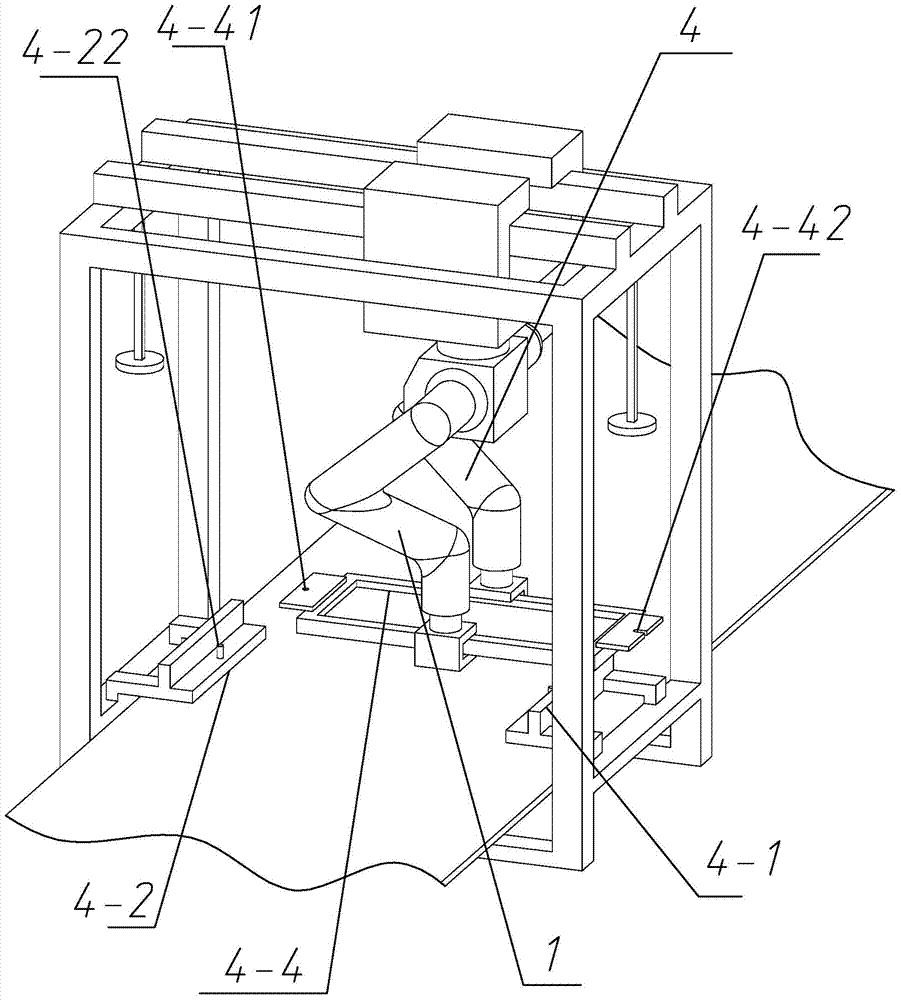

[0029] specific implementation plan

[0030] With reference to accompanying drawing, the present invention comprises frame 103, and two ends are provided with flat screen printing belt guide roller 102 on the frame 103, and flat screen printing belt guide 3 is installed on the flat screen printing belt guide roller 102, and described frame 103 also A pneumatic screen support frame and a frame 110 are installed to drive the screen to move up and down. A lateral movement guide rail 6 is arranged above the frame 110. The robot 101 is installed on the lateral movement guide rail 6. The lateral movement guide rail 6 moves laterally under the drive of the motor. , to realize the lateral movement of the robot 101, the printing guide belt 3 passes through the frame 110, and the screen clamping device, the slurry poking clamping device, the scraper are installed in the frame 110. clamping device, Figure 14 The position A shown in the figure is the placement position of the color past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com